Predictive and Preventive Maintenance

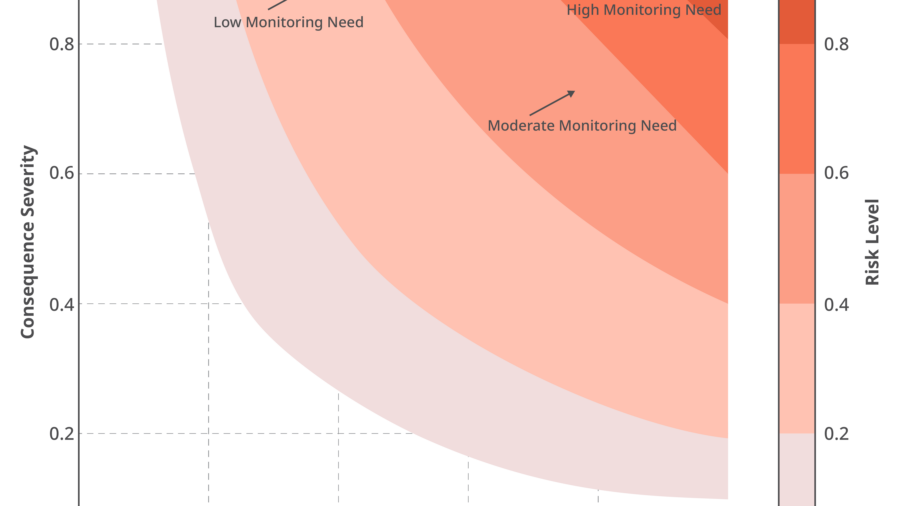

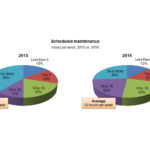

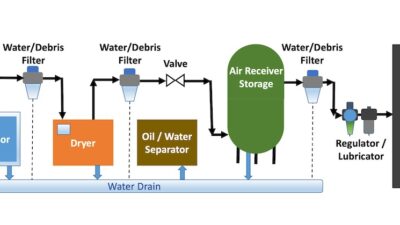

Predictive maintenance is a strategy for maintaining industrial equipment and machinery that involves using data and analytics to predict when equipment is likely to fail, so that maintenance can be performed before the failure occurs. This approach allows organizations to schedule maintenance during planned downtimes, rather than having to perform it as an emergency reaction when equipment failure occurs, which can cause significant disruptions to production and lead to costly downtime. Preventive maintenance (PM) is a strategy for maintaining industrial equipment and machinery that involves performing regular inspections, cleaning, testing and maintenance tasks on a set schedule to detect and prevent equipment failures before they occur. The goal of preventive maintenance is to reduce the likelihood of equipment failure and prolong the useful life of the equipment which can result in cost savings and improved overall equipment performance.