Choosing the right grease and proper grease application are essential for implementing a sound lubrication strategy and preventing costly mechanical failures.

Grease insights

- Using high-performance greases and following best lubrication practices can significantly improve equipment longevity, reduce downtime and enhance overall operational efficiency.

- This article will explore best practices for selecting and applying the right high-performance grease to help enhance equipment’s durability and efficiency.

One of the most important components in any manufacturing plant is the lubrication of its machinery and equipment. Lubricants play a vital role in the performance and longevity of any machinery.

Unfortunately, a significant percentage of mechanical failures are caused by lubrication issues, often due to improper grease selection, contamination or breakdown under stress. Bearings seize, robotic joints fail and construction equipment grinds to a halt, not because of mechanical defects, but because the wrong grease was applied or the right grease couldn’t withstand extreme conditions.

The good news is that these failures are entirely preventable with the proper grease selection and application.

Understanding the science behind grease and how its key components impact load performance and shear stability in varying applications can help optimize equipment performance and liability. Choosing the right grease helps avoid common lubrication pitfalls, reducing failures and improving machinery longevity.

The science behind grease: a precision-engineered solution

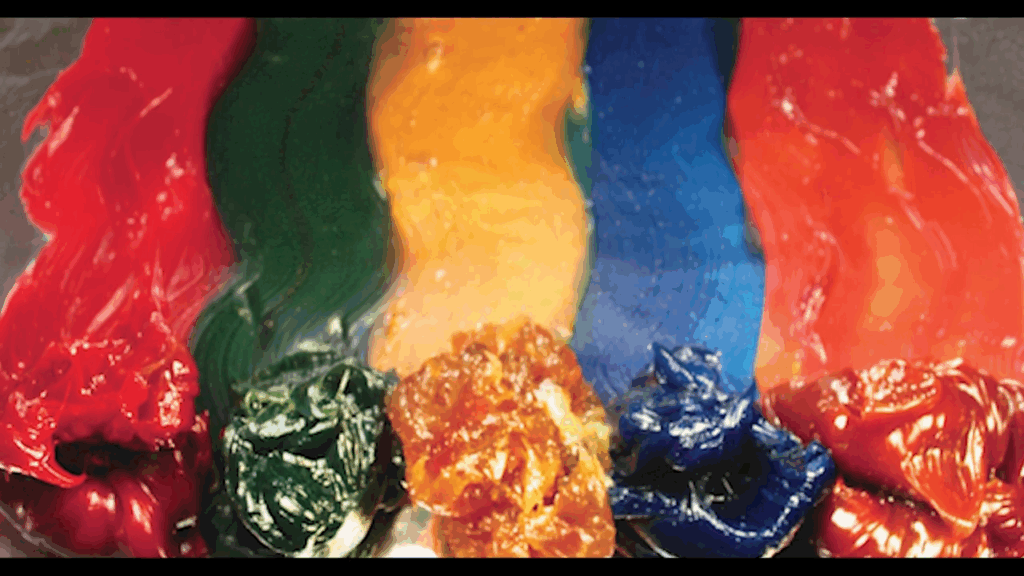

Whenever a new machine or component is installed, one of the first things to be addressed is the type of lubricant or grease to use. Lubricating grease is a semi-solid structure that consists of three main components: oil, additives and thickener and it is used primarily to reduce friction in several critical components and applications.

Understanding the key properties of grease can help operators in the selection of the right lubricant for their operational needs. There are three main properties:

Base oil type: The base oil type is crucial in selecting the right grease for machinery as it determines the grease’s performance under different operating conditions, such as temperature, load and speed. Base oils make up 80% to 90% of grease, so their properties impact the grease’s ability to lubricate effectively. The American Petroleum Institute has five base oil designations and characteristics:

- Group I, II and III are base oils derived from crude oil, suitable for general applications but can break down at extreme temperatures or loads.

- Group IV and V are synthetic base oils that are ideal for a wide range of temperatures and extreme conditions, providing greater resistance to oxidation, temperature changes and wear.

Base oil viscosity: Grease is made up of 80% to 90% oil, which makes the viscosity of the base oil crucial. Viscosity affects the oil’s resistance to flow and plays an important role in maintaining proper lubrication, preventing wear and reducing excessive heat.

Additive package: Additives enhance grease with antioxidants and corrosion inhibitors, modify base oils properties with pour-point depressants and viscosity index improvers and provide grease with extreme pressure characteristics and metal deactivation.

Consider extreme pressure greases

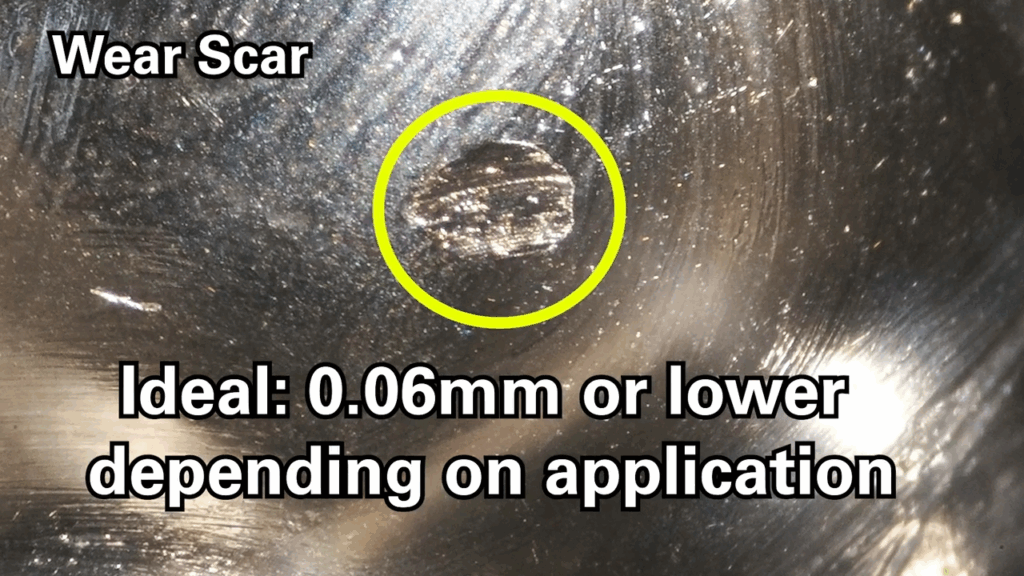

An extreme pressure (EP) grease is specifically formulated to handle heavy shock loads and high-pressure environments, providing protection against wear, contamination and environmental factors while prolonging the life of bearings and other components.

EP greases are enhanced with additives like graphite and molybdenum disulfide (known as “moly”), creating an extra barrier between machine surfaces. These greases can withstand extreme temperatures and pressures and offer water resistance to wash-out and corrosion in moist environments.

EP greases are rigorously tested for water resistance and pressure handling ability, with grading based on performance.

Why greases fail: common lubrication pitfalls

When implementing an ineffective lubrication strategy, plant operators often make mistakes that can negatively impact equipment wear, lifespan and overall efficiency. These errors can also lead to costly repairs and unplanned downtime.

- Failure mode 1: Lack of EP protection: High-load applications such as robotic automation, construction equipment and hydraulic systems require EP additives to prevent excessive wear. Non-EP greases without moly or calcium sulfonate shear under pressure, leading to metal-on-metal contact and overheating.

- Failure mode 2: High-temperature breakdown: An important indicator of quality in grease is its dropping point — the temperature at which it passes from a semisolid state to a liquid under defined test conditions. A grease should have a dropping point that is safely above the highest operating temperature to avoid run-out during application. Using a grease that exceeds its dropping point leads to the grease losing its ability to lubricate and creating wear and potential machinery failure.

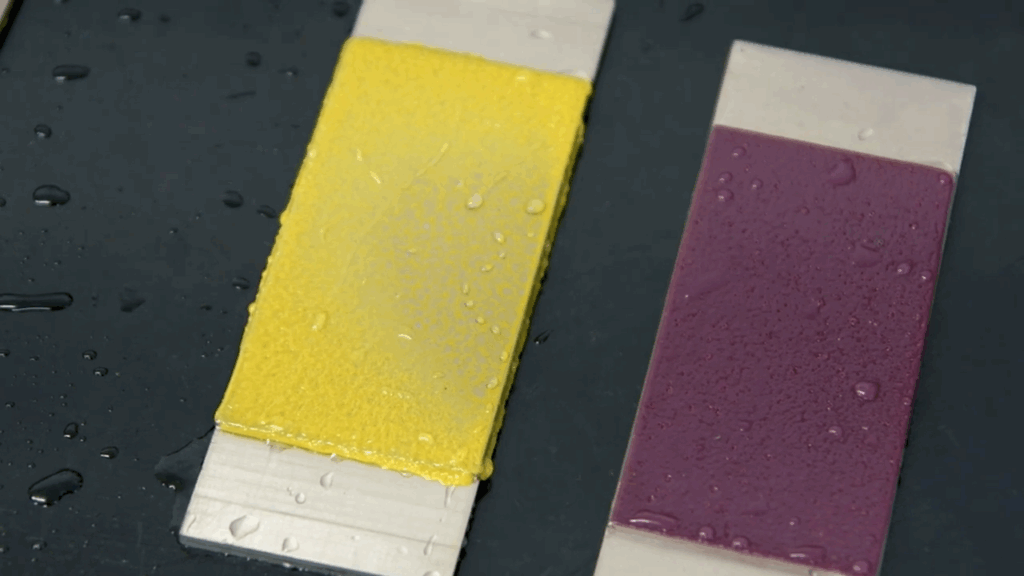

- Failure mode 3: Contamination and water washout: Using greases with low water resistance can create washout and increase risk of contamination. Water can weaken the structure of grease, washing away lubrication and leading to higher friction and wear.

How high-performance greases improve equipment longevity

Implementing a sound lubrication approach featuring the right high-performance greases can help operators enhance equipment longevity, as these formulations offer specialized protection against common wear factors. Key benefits include:

- EP greases with moly additives reduce wear under extreme pressure, making them ideal for heavy equipment, manufacturing machinery and industrial robotics.

- Calcium sulfonate thickeners provide built-in EP protection, ideal for industrial bearings and hydraulic systems.

- Synthetic base oils prevent oxidation and breakdown in extreme heat, while lithium- and aluminum-complex greases have higher dropping points to ensure continuous lubrication.

- Polymer-enhanced greases improve water resistance, preventing contamination-related failures.

Best practices for grease selection and application

To maximize machinery performance, efficiency and lifespan, operators should follow these best practices when selecting and applying grease:

- Follow original equipment manufacturer recommendations: It is recommended to follow manufacturer guidelines or consider load, temperature and environmental conditions when choosing a grease.

- Choose the right formulation: It’s important to choose the right grease for the application, such as EP greases for high load conditions and synthetic-based greases for extreme temperatures.

- Implement a preventive lubrication strategy: Regularly monitoring and addressing potential contamination risks will help maintain ideal grease performance.

Lubrication as an engineering strategy

Lubrication is not just a maintenance task; it is a critical engineering strategy that directly impacts equipment lifespan, operational efficiency and cost savings. Proper grease selection is crucial in reducing premature equipment failures, as it ensures optimal performance and longevity of machinery components.

With the right grease, equipment runs longer, breakdowns are reduced and businesses save money. Instead of treating lubrication as an afterthought, companies should integrate lubrication into their performance and reliability strategies.

To take lubrication strategy to the next level, assess a production facility’s current grease selection and determine if it is optimized for load, temperature and contamination risks. Upgrade to an EP, high-temperature or polymer-enhanced formulation where needed.