Energy harvesting is revolutionizing industrial operations by transforming ambient energy, such as heat, into electrical power

Learning Objectives

- Understand the role of energy harvesting technologies in industrial applications, specifically how they convert thermal energy into electrical power to enhance operational efficiency and reduce environmental impacts.

- Learn about the applications and benefits of energy harvesting in predictive maintenance and remote monitoring and how it supports continuous operation and data-driven decision-making.

- Explore the sustainability benefits and future potential of energy harvesting, including its ability to reduce waste and emissions and its integration with renewable energy sources and advanced digital technologies.

Energy harvesting insights

- Energy harvesting technology enhances operational efficiency and environmental sustainability by enabling remote monitoring and predictive maintenance without reliance on traditional power sources.

- Thermoelectric generators (TEGs) used in energy harvesting not only convert waste heat into electrical power, enabling sensors on industrial machinery to operate continuously without external power sources, thus significantly enhancing predictive maintenance and remote monitoring capabilities.

The push for sustainability is reshaping global industries, compelling them to embrace innovative technologies that optimize operations and minimize environmental impacts. Among these technologies, energy harvesting stands out prominently. This method converts ambient energy, such as heat, into usable electrical power and is proving particularly critical in applications like wireless sensors for remote monitoring and predictive maintenance.

By revolutionizing how industries manage power consumption, energy harvesting is playing a key role in enhancing both operational efficiency and environmental sustainability.

The role of energy harvesting in industrial applications

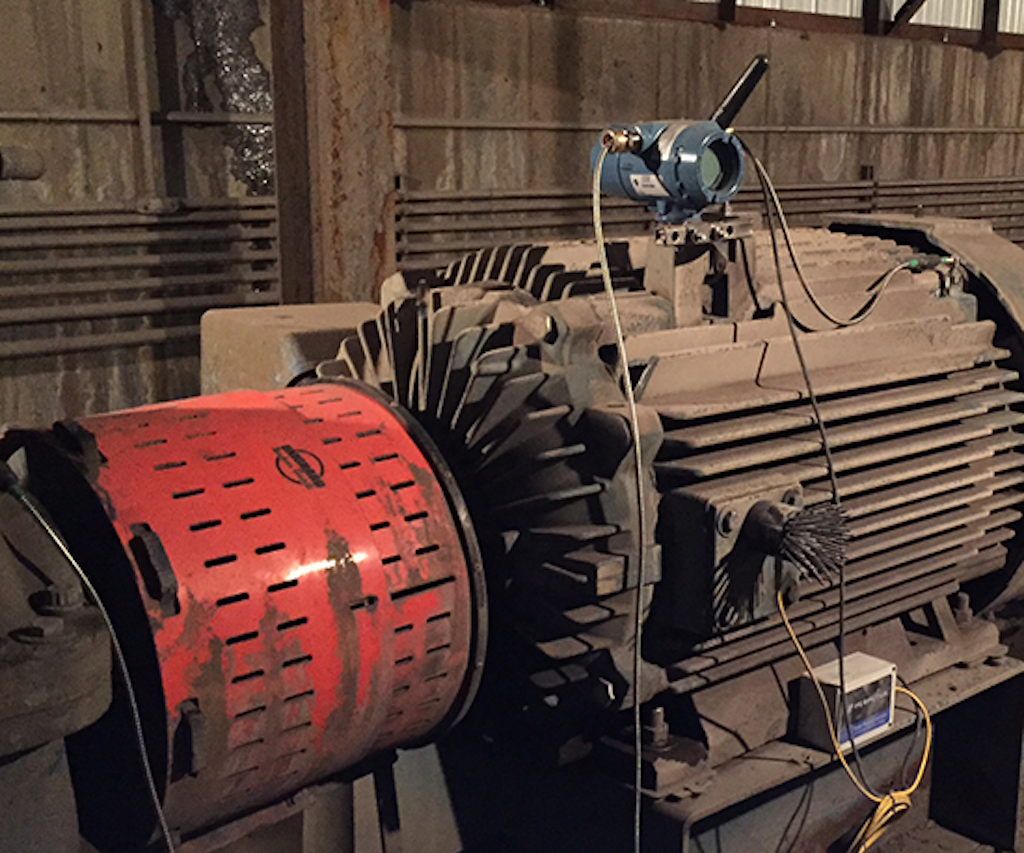

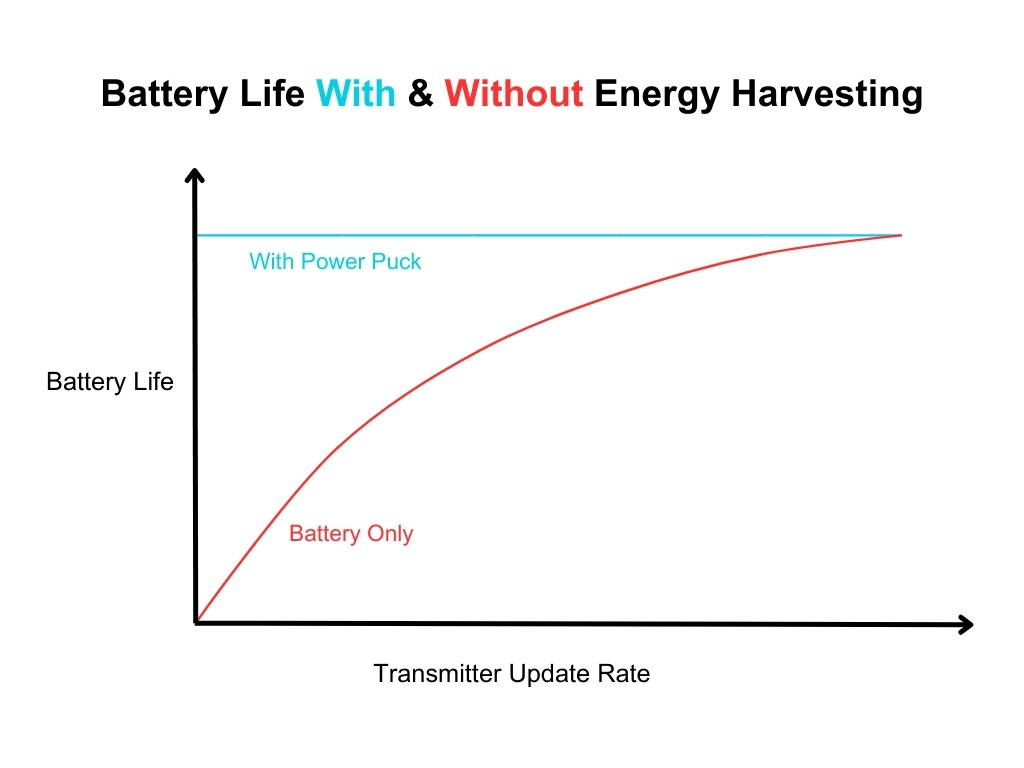

Energy harvesting technologies, especially those converting thermal energy into electrical power, offer robust solutions for powering devices in locations where traditional power sources are impractical. Industrial sensors, which are crucial in monitoring operational parameters in remote or hazardous environments, traditionally depend on batteries.

However, batteries are costly, require frequent replacement and pose significant environmental burdens from manufacturing, transportation and disposal processes.

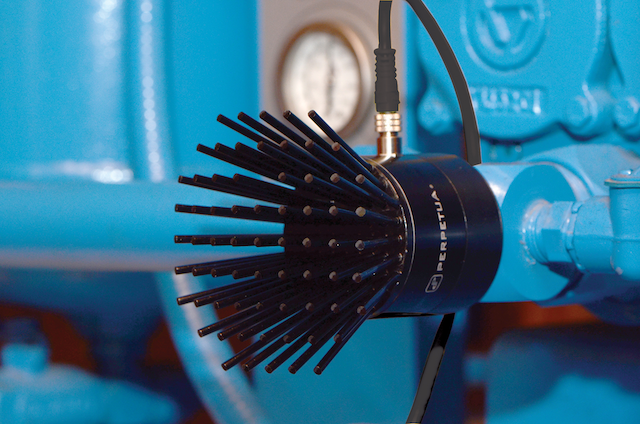

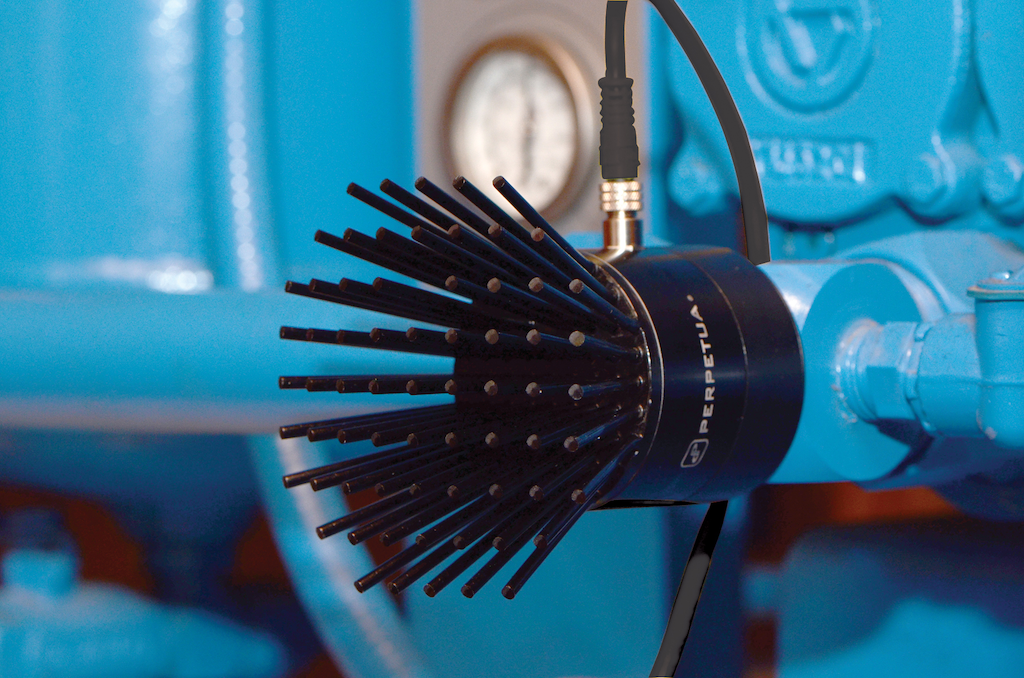

Thermoelectric generators (TEGs), operating on the Seebeck effect — the direct conversion of temperature differences into electricity — exemplify effective energy harvesting devices. These devices are ideal for industrial settings where heat is routinely produced as a byproduct. For instance, sensors mounted on factory machinery can use the machine’s heat output to generate power through TEGs, ensuring continuous operation without the need for external power sources.

Enhancing predictive maintenance and remote monitoring

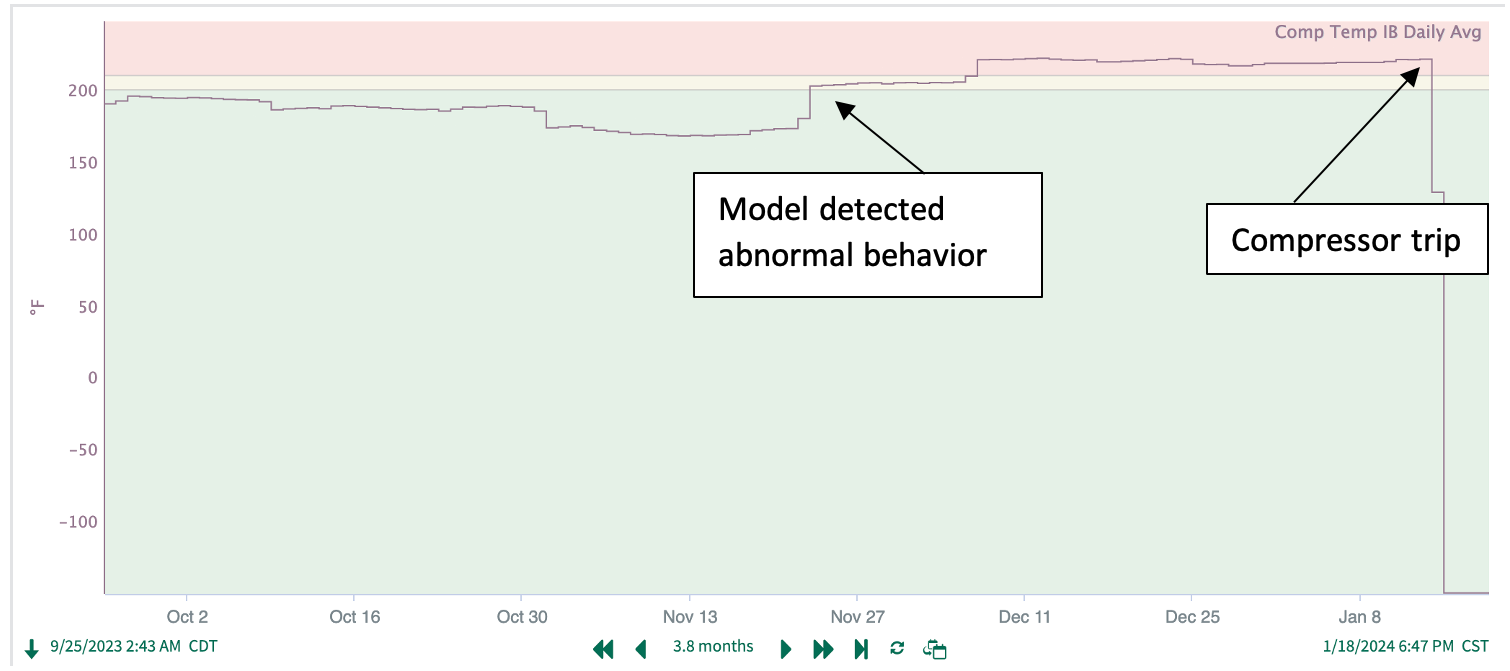

Energy harvesting significantly boosts the effectiveness of predictive maintenance and remote monitoring across various industries by providing a dependable and continuous power source for sensors. This continuous power supply is crucial as it allows sensors to consistently monitor and transmit data regarding the health of equipment, which is essential for timely maintenance and preventing potential failures.

The integration of energy harvesting technologies enables deeper and more complex sensor networks. With sensors that do not rely on traditional power sources, industries can place them in more remote or less accessible areas of machinery or infrastructure. This broader deployment allows for the collection of more comprehensive data, which can be used to create a detailed picture of equipment health and operational conditions.

The data collected from these sensors can feed into sophisticated predictive analytics and machine learning algorithms. These technologies can analyze patterns and predict potential failures with greater accuracy than ever before.

For instance, sensors on a turbine could detect subtle changes in vibration patterns that precede a mechanical failure, allowing maintenance teams to address the issue before the turbine experiences a catastrophic breakdown.

Sustainability benefits of energy harvesting

Adopting energy harvesting technologies can substantially reduce environmental waste associated with conventional battery use. These technologies minimize the hazardous waste and carbon emissions produced during the battery lifecycle by eliminating the need for batteries altogether. Additionally, using ambient energy as a power source significantly lowers a facility’s overall energy consumption, supporting global sustainability goals aimed at reducing carbon emissions and environmental degradation.

Energy harvesting’s potential to lessen environmental impacts is well recognized. Renewable energy sources like solar and wind, which are often used in energy harvesting, are generally considered more environmentally friendly than traditional fossil-fuel-based resources. They typically result in lower air and water pollution and do not produce harmful carbon dioxide emissions that contribute to climate change.

Despite these benefits, it’s essential to consider that all energy sources, including renewables, have some impact on the environment. These impacts can vary greatly depending on the technology and scale of the implementation but are generally less detrimental than those associated with nonrenewable energy sources.

Practical applications of energy harvesting

Energy harvesting technologies are making significant strides across various sectors. In the oil and gas sector, energy harvesting technologies are increasingly used to enhance operational efficiency and safety. These industries, characterized by remote and harsh environments, benefit significantly from deploying TEGs. These devices are particularly valuable in capturing waste heat from high-temperature processes such as flaring, refining or gas compression to generate electricity. This not only recycles energy that would otherwise be lost but also powers sensors and monitoring equipment crucial for maintaining system integrity and detecting early signs of equipment failure.

In the manufacturing sector, TEGs are employed to capture waste heat from industrial processes, converting it into electrical energy. This technology is particularly useful in environments with significant temperature gradients, where it can enhance energy efficiency by using the heat produced by machinery or industrial processes.

The future of energy harvesting

The future of energy harvesting appears bright as digital transformation continues to influence various industries. Advances in materials science and improvements in thermoelectric efficiency are expected to expand the practical applications of these technologies, making them more effective across a variety of operational conditions. Additionally, the potential for integration with other renewable energy sources, such as solar or kinetic energy, suggests the development of hybrid systems that provide even greater reliability and flexibility.

The integration of energy harvesting with the internet of things and artificial intelligence technologies promises to further revolutionize industrial maintenance and monitoring. Smart sensors that cannot only collect but also analyze data in real time will dramatically improve the ability of industries to predict and preempt equipment failures. This advanced integration represents a significant move toward fully automated, self-sustaining industrial systems that are efficient and environmentally responsible.

Long-term economic and environmental impact

The long-term benefits of integrating energy harvesting into industrial applications extend beyond immediate operational improvements. Economically, the reduced need for maintenance and the extended life span of equipment can significantly lower overall costs. Environmentally, decreasing reliance on nonrenewable power sources and reducing waste production contribute substantially to a smaller carbon footprint, aiding industries in meeting stringent environmental regulations and fulfilling public expectations for sustainable operations.

Energy harvesting is reshaping the landscape of industrial innovation, sustainability and operational efficiency. As industries strive to reduce their environmental footprints while enhancing data-driven decision-making, technologies that use ambient energy sources, such as heat, are becoming increasingly essential. With ongoing advancements, energy harvesting is set to revolutionize industrial power management, establishing a new standard for sustainable industrial practices.