The right maintenance, repair and operations (MRO) plan can save manufacturing facilities a lot of trouble in the long run if companies take ownership and find the right resources.

Respondents

- John Gaddum, factory automation service manager, Bosch Rexroth, Hoffman Estates, Ill.

- Lance Gilbert, managing partner, Net Results Group, Louisville

- Pratibha Pillalamarri, senior product marketing manager, Aspen Technology, Houston

Question: What are the key challenges faced by organizations in managing MRO activities effectively?

John Gaddum: Taking ownership and finding dependable resources for reliable repairs. Most companies don’t put much analysis into their repairs and end up losing a lot of time and money from substandard repairs.

Lance Gilbert: The key challenges faced by organizations in effectively managing MRO activities include an aging workforce and the subsequent turnover, where there is a need for younger, technologically savvy resources. The aging workforce often possesses inherent knowledge and experience crucial for MRO activities, and as they retire or leave, organizations face the risk of losing valuable institutional knowledge. The challenge lies in bridging the gap by attracting and retaining younger talent with the requisite technological skills to ensure continuity and proficiency in MRO operations.

Question: How do you prioritize maintenance tasks to ensure optimal equipment performance and longevity?

Lance Gilbert: To prioritize maintenance tasks for optimal equipment performance and longevity, companies often grapple with the challenge of insufficient visibility into their storerooms, particularly across the entire enterprise. A crucial aspect is gaining a comprehensive understanding of available inventory, ensuring accurate and up-to-date records of spare parts and essential components.

This visibility enables informed decision-making, allowing maintenance teams to prioritize tasks based on criticality, availability of resources, and overall impact on equipment performance. Addressing the challenge of inventory management is foundational to implementing an effective and strategic approach to prioritize maintenance tasks and enhance equipment reliability.

Pratibha Pillalamarri: Maintenance tasks can be prioritized by evaluating equipment criticality based on production, safety and environmental impact. These include:

-

Prioritizing critical assets to minimize disruptions

-

Utilizing predictive maintenance solutions to detect issues as they form

-

Scheduling proactive tasks guided by predictive alerts

-

Assessing risks associated with maintenance and prioritizing accordingly to ensure safety and continuity

-

Considering resource availability for efficient task completion

-

Performing cost-benefit analyses to prioritize tasks that result in highest performance and reliability improvements while reducing downtime.

This cohesive approach enhances equipment reliability and efficiency by leveraging solutions that assess criticality, quantify risks, provide prescriptive guidance and optimize maintenance scheduling.

Question: In your experience, what role does technology play in streamlining MRO processes and reducing downtime?

Lance Gilbert: In my experience, technology plays the paramount role in streamlining MRO processes, positioning it as the number one priority. MRO is a significant contributing factor to achieving operational efficiency and maintaining a competitive edge in the market. Leveraging technology in MRO processes is instrumental in reducing downtime by optimizing asset performance, enabling predictive maintenance and ensuring efficient inventory management.

The integration of technologies such as predictive analytics, condition monitoring and robust enterprise asset management (EAM) systems enhances decision-making, minimizes unplanned downtime and contributes to achieving cost-effective and competitive operations.

Question: Can you share examples of successful MRO cost reduction initiatives that you’ve implemented or witnessed?

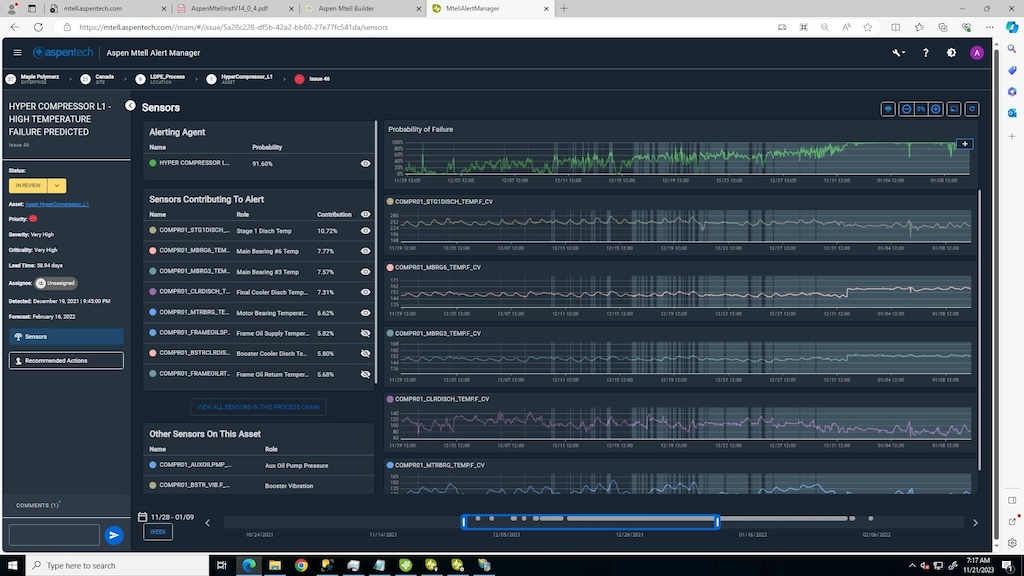

Pratibha Pillalamarri: In one case, OCP Ecuador utilized a prescriptive maintenance solution to enhance the availability and reliability of pumps and generators. Within six weeks of implementation, they achieved impressive results, including a 20% increase in uptime and a 25% reduction in annual maintenance expenses. The solution also extended the camshaft lifespan from 20,000 to 50,000 hours, leading to substantial cost savings.

In another, a large chemical company in Asia implemented a prescriptive maintenance solution across two complexes, deploying over 200 live agents to protect various equipment such as compressors, pumps and reactors. The solution provided early warnings to prevent unplanned shutdowns, enabling production loss avoidance and shutdown prioritization for maintenance planning. The estimated annual value protected by avoiding downtime reaches up to $3.6 million.

Question: What metrics do you consider most important for measuring the effectiveness of MRO operations and what role do analytics play?

Lance Gilbert: The key metrics for measuring MRO effectiveness include improved capacity, equipment availability and cash flow. Analytics play a crucial role in interpreting these metrics, providing insights for data-driven decision-making and optimizing MRO strategies.

Question: What challenges do you encounter when managing MRO for a diverse range of equipment and assets?

Lance Gilbert: Managing MRO for a diverse range of equipment and assets presents challenges such as unplanned outages and decreasing maintenance productivity. The varied nature of equipment requires a strategic approach to ensure timely and effective maintenance, minimizing disruptions and optimizing overall productivity. Addressing these challenges involves implementing proactive maintenance strategies, leveraging technology and adopting a holistic MRO approach tailored to the diverse asset portfolio.

Question: How do you ensure effective communication and collaboration between maintenance teams and other departments?

Lance Gilbert: Ensuring effective communication and collaboration between maintenance teams and other departments involves implementing team-building exercises and fostering an understanding of each other’s operations. By promoting a collaborative culture and facilitating opportunities for teams to interact and comprehend the nuances of different departments, organizations can enhance communication channels and strengthen the synergy between maintenance and other functional areas.

Pratibha Pillalamarri: Encourage cross-training initiatives to familiarize employees with different departments’ functions and promote knowledge sharing. This facilitates better understanding and collaboration between teams. Implement solutions that consider equipment within the broader context of processes, rather than viewing it in isolation. A comprehensive maintenance strategy encompasses not only the equipment itself but also its upstream and downstream processes.

Such a solution evaluates the impact of processes on equipment and offers a dashboard to facilitate task management and insight sharing, thereby enabling cross-departmental collaboration. By implementing these strategies, organizations foster effective communication and collaboration, leading to improved efficiency, productivity and overall success.