In our Facebook-obsessed, Twitter-gone-mad world, you can find out anything instantly. It should come as no surprise that most of the stuff you find out is stuff you don't need to know. We now live in a world where professional athletes Twitter from the bench and one major news story – the death of Michael Jackson – can bring an entire system to its knees.

In our Facebook-obsessed, Twitter-gone-mad world, you can find out anything instantly. It should come as no surprise that most of the stuff you find out is stuff you don’t need to know.

We now live in a world where professional athletes Twitter from the bench and one major news story — the death of Michael Jackson — can bring an entire system to its knees. Everyone apparently needs to talk to everyone about everything all the time. Yet we don’t always want or need to know everything about everyone. We are left to sort through the sludge to find the gold.

So the challenge today is not the availability of information. The trick is to separate the stuff you need to know from the stuff you are being told, and then to further separate the stuff you need to know from the stuff you need to know NOW. In journalism, we call that editing. In the business of manufacturing, we call that productivity.

In manufacturing, information can save us or drown us. It is at once both the giant wave coming to sweep us away and the lifesaver to keep us afloat. In calm waters or choppy seas, information surrounds us and sustains us.

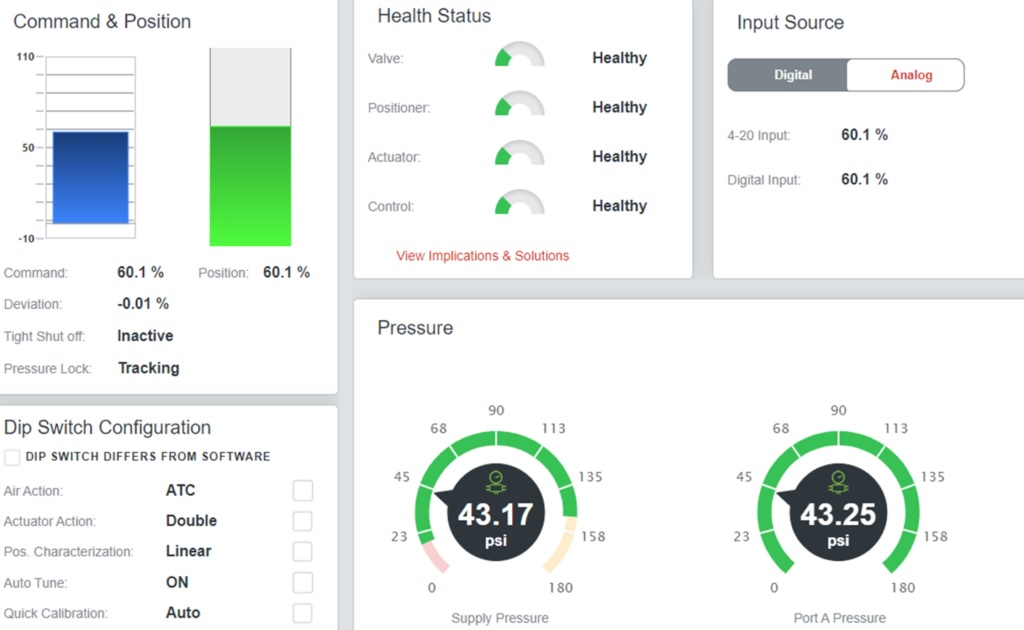

The ability to deliver a lot of information to the operator is remarkable. Want to know the temperature on your steam valves? It’s right there. Need to know the throughput of Line 5? Just press the right key. How much energy is being consumed in the day shift vs. the night shift? There’s a dashboard that can be automatically sent to your BlackBerry at 11 p.m.

But is that what you need to run an effective manufacturing plant? The data is accurate, but is it necessary?

When you’re drowning in data, here’s an S.O.S. call to help yourself out from under the mountain of data heading into your operation: What you want is data that is:

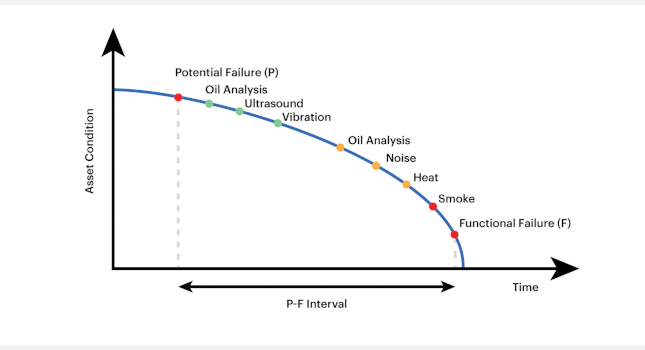

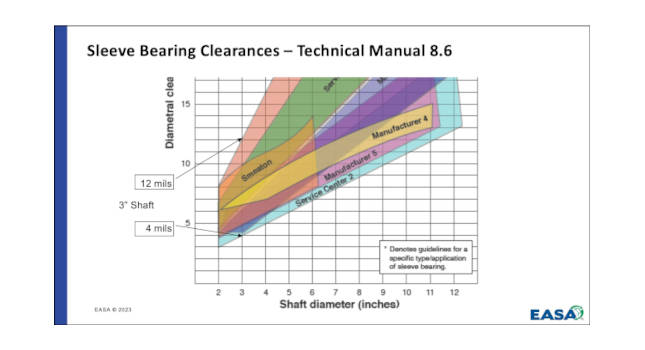

Strategic : You need information that addresses the long-term health of your plant. For example, there are temperature- or vibration-monitoring devices that give you a look at the future of your equipment. These can be used to plan maintenance — and we know from Plant Engineering data that most of you don’t plan maintenance. For the hundredth time: Run-to-failure isn’t a strategy.

The economic downturn has provided many manufacturers with a chance to look at their long-term plans and decide what the future of their operation could look like. You have to take time to think long-term.

Operational : The ability of a good plant manager to understanding what’s happening on his floor is that perfect mix of great data and what an old boss of mine called MBWA — Management By Wandering Around. A plant manager can wander right to the source of problems with good data. He can see the trouble spots, or find the productivity increases, and address both issues promptly. Sometimes, finding what works better than expected is as valuable as finding what’s not working. Best practices, shared with your team, can help pave the way to more improvements. Information helps you find those nuggets more easily.

Seismic : Stuff breaks. Lines crash. It is in these moments of crisis when a good manager rises to the occasion. Information delivered quickly to plant team members can help operations recover more quickly from the operational earthquakes that affect every facility at one time or another. If you’ve done a good job with the first two areas, of course, seismic events are less likely to occur and easier to overcome.

But the first step is to sift through the information that lands on your doorstep and desktop. We’d like to think we’re part of that information process, and so I’d always like to know what information you need, when you need it and what the best way is to deliver it to you.

I am connected through Twitter ( twitter.com/bobvavra ) and through the Plant Engineering magazine page on LinkedIn. I also have an email address, and the last time I checked, I also had a phone, but that may be too 20th Century for some people.

As someone who spends all day with information, the key is to sort through all of that knowledge in some meaningful, manageable way. In the end, it is a matter of editing. The correct question is not, “What do I need to know now?’ but rather, “NOW what do I need to know?”