Ultra-Slim Altivar 32 Drive from Schneider Electric optimizes panel space, reduces wiring, adds functionality to save time and money

Schneider Electric has announced a new variable speed drive, the Altivar 32, which provides a high degree of performance and connectivity by reducing panel space, improving uptime and maximizing machine performance. With its ultra-slim, book-style design and the ability to directly attach a self-protected disconnect, the Altivar 32 allows users to mount it side-by-side and integrate it into tight spaces, minimizing wiring and machine costs.

“The Altivar 32 is the first industrial drive that has the capability to integrate a self-protected disconnect, thereby offering our customers significant time and cost savings,” said Ivan Spronk, product marketing manager, Schneider Electric. “In addition, this drive has certified safety functions for safe power removal, safe limited speed and safe stopping, as well as integrated decision capabilities, such as input/output (I/O) event logic, counting and timing functions further reducing panel space and wiring costs.”

The drive can operate as the heart of a simple control system and perform functions usually managed by a PLC, which allows users to use Boolean and arithmetical operations, timers, counters, comparators, and short automated sequences to customize the drive to specific machine application and save on installation components. All of these functions can be programmed using Schneider Electric’s SoMove software, available for free at www.schneider-electric.us/go/drives.

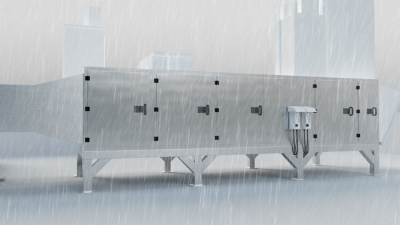

Designed to operate without the need for encoder feedback, the Altivar 32 drive delivers exceptional speed and torque control for asynchronous or synchronous AC motors. It also features conformal coating to protect circuit boards from dust, moisture and other airborne contaminants, which allows it to be used in harsh environments.

To further enhance the user experience, Altivar 32 is embedded with Bluetooth technology which enables monitoring, viewing and performing machine diagnostics while keeping cabinet doors safely closed. It also includes standard RJ45 connectors for Modbus and CANOpen networks, and onboard HMI and navigation wheel for easy adjustments.

“Challenged by tougher economic conditions, machine builders expect solutions that are easier to use and maintain, but at the same time generate higher return on investment,” adds Spronk. “By taking advantage of Altivar 32 drive’s multiple innovative features, OEMs can deliver cost-effective solutions, while improving their machine performance.”

Schneider Electric

– Edited by Amanda McLeman, Plant Engineering, www.plantengineering.com