Siemens has now extended the lower power range of synchronous reluctance technology from 5 down to 0.55 kilowatts (kW). The synchronous reluctance drive systems from Siemens now cover the complete power range from 0.55 kW to 30 kW.

Siemens has now extended the lower power range of synchronous reluctance technology from 5 down to 0.55 kilowatts (kW). The synchronous reluctance drive systems from Siemens now cover the complete power range from 0.55 kW to 30 kW. In addition to the previously available shaft heights from 132 to 200, motors are now offered with shaft heights ranging from 80 to 120. A reluctance motor and an inverter specifically matched to one another form an Integrated Drive System (IDS), and enable especially efficient operation in comparison to induction motors. Predefined parameters in the form of a code on the motor rating plate simplify commissioning. Reluctance technology is used in process technology with pumps, fans, compressors, mixers and centrifuges, as well as in conveyor technology and mechanical engineering.

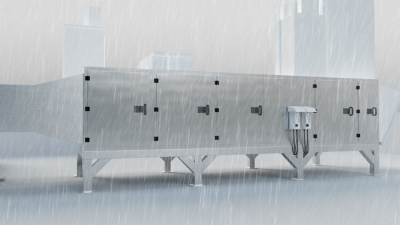

The new drive series is based on the 1LE1 Simotics motor platform, featuring a similar design and handling, and is matched to the Sinamics G120 inverters. The power range of Simotics reluctance motors has now been extended to cover the range from 0.55 to 30 kW. The motors are available with aluminum enclosures for general ambient conditions (Simotics GP) or with gray cast iron enclosures for severe ambient conditions (Simotics SD). In the partial load range, reluctance motors are considerably more efficient than induction motors of the same power.

The synchronous principle ensures that the speed remains constant. Furthermore, the sensorless vector control optimizes performance. These two characteristics enable efficient control of the drive system. A motor with a low intrinsic moment of inertia and vector control offers the advantage of short run-up times. The low losses in the rotor also facilitate high thermal utilization of the motor. For example, this enables the motor to be operated at 87 Hz with some 70 percent higher power.

The Sinamics G120 standard inverter is equipped with vector control specifically designed for the reluctance motors. Identification of the pole position at switch-on prevents jerking movements of the drive. The devices can be integrated into any automation solution, such as TIA (Totally Integrated Automation), by means of Profibus and Profinet interfaces.

– Edited from a Siemens press release by CFE Media.