Air compressors are among the most energy-intensive systems in industrial facilities, but with the right asset management strategies, companies can significantly reduce energy consumption, improve reliability and support sustainability goals.

Air compressor insights

- Smart asset management best practices include inventory mapping, key performance indicator (KPI) tracking and energy recovery.

- Data is a critical component for reducing energy usage in air compressor systems.

- Worker training programs are a significant factor in maintaining energy-efficient air compressor systems.

Energy efficiency is not a trend; it’s a strategic necessity for industrial businesses. Air compressors are a prime target for optimization as one of the most energy-intensive systems in manufacturing, consuming up to 30% of a facility’s total electricity. The key to unlocking this opportunity lies in smart asset management.

By systematically monitoring, maintaining and optimizing air compressor systems, companies can achieve significant energy and cost savings.

Understanding industrial asset management

In industrial settings, asset management is a strategic process that ensures equipment is continuously monitored, maintained and optimized throughout the life cycle. Increasingly, companies are turning to digital, data-driven solutions that enable real-time tracking, predictive maintenance and operational control through integrated platforms.

These systems allow manufacturers to compare production data with quality metrics, access live service updates and streamline maintenance using mobile tools and cloud-based technology. By incorporating life cycle planning and energy performance tracking, modern asset management solutions improve productivity, reduce downtime and futureproof operations.

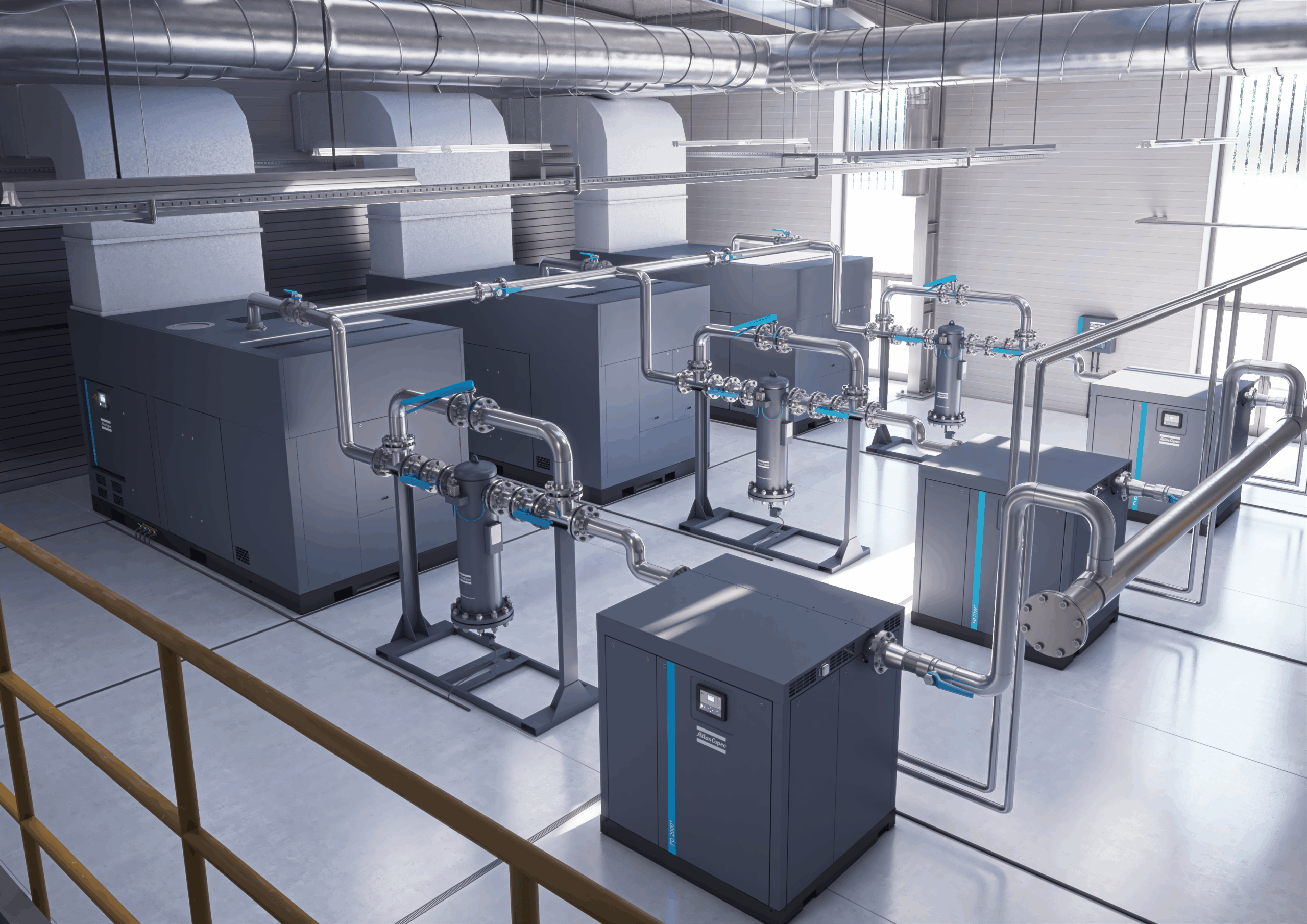

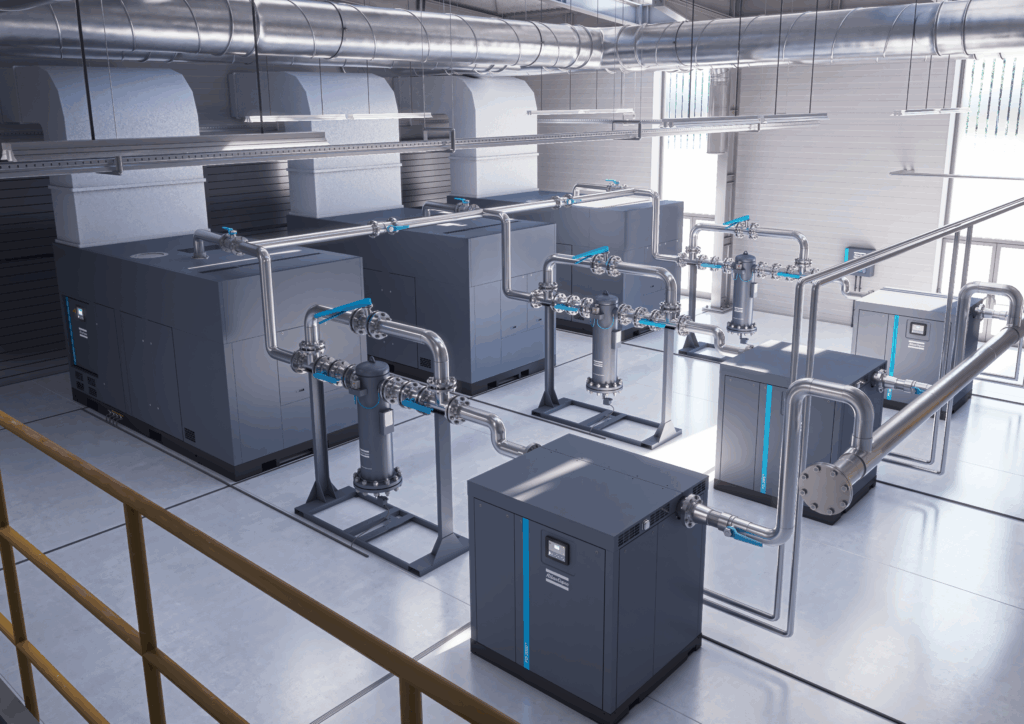

For air compressors, effective asset management includes life cycle planning, performance monitoring, predictive maintenance and operational optimization. Integrated platforms support real-time tracking, automated service alerts and data-driven decision-making, all of which are essential to maintaining uptime and improving energy efficiency.

Smart asset management strategies, such as system audits, leak detection, pressure optimization and energy recovery, can substantially cut energy waste and operating costs. Diagnostic tools that evaluate the entire compressed air network help uncover inefficiencies and offer actionable insights for continuous improvement. By adopting these strategies organizations can enhance reliability, reduce expenses and make meaningful progress toward sustainability goals.

The role of air compressors in industrial operations

Air compressors are foundational to industrial operations, powering applications from pneumatic tools and process equipment to automation systems. Compressors worldwide are specifically tailored to industries like manufacturing, food and beverage and automotive sectors where a continuous, clean air supply is essential for precision, reliability and safety.

Despite their utility, air compressors are often among the largest energy consumers in a facility and inefficiencies can significantly inflate operational costs. The challenge is addressed through innovations like variable speed drive (VSD) technology, which can reduce energy consumption by up to 35% and monitoring systems that detect leaks and pressure drops early.

Common inefficiencies such as over-pressurization, poor system sizing and lack of maintenance are mitigated through proactive diagnostics and tailored service plans. These solutions not only enhance performance but also contribute to sustainability goals by minimizing energy waste and extending equipment lifespan.

Three key elements of air compressor asset management

There are three major components of asset management for air compressors.

1. Inventory and asset mapping

Effective asset management for air compressors starts with inventory and asset mapping. Cataloging all compressor systems, including their age, condition and usage patterns, provides a clear picture of operations. This baseline allows facilities to prioritize maintenance, allocate resources wisely and plan for future upgrades. Auditing tools can then be used to assess the entire compressed air system, from generation to distribution, identifying inefficiencies and offering actionable insights.

2. Data collection and monitoring

Monitoring and data collection are essential for sustaining performance and reliability. Most compressor manufacturers offer platforms that track key parameters such as pressure, temperature and power usage in real time. These internet of things-enabled tools give operators visibility into daily operations and support predictive maintenance by identifying trends and anomalies before they cause failures. For example, vibration, oil and thermal analysis can detect early signs of wear, enabling maintenance teams to act proactively and prevent costly downtime.

3. Performance benchmarking and life cycle management

Performance benchmarking and life cycle management complete a strong asset management strategy. By tracking key performance indicators (KPIs) such as specific power (kilowatts/100 cubic feet per minute), runtime efficiency and leak rate, companies can pinpoint underperforming units and make informed decisions about retrofitting, upgrades or replacements. With tools like return on investment (ROI) calculators and energy efficiency rebates, organizations can invest wisely while also supporting sustainability goals by reducing energy use and carbon emissions.

Benefits of effective asset management for energy efficiency

By leveraging smart technologies like VSD compressors and real-time data assessment, companies can significantly reduce energy costs and lower their carbon footprint. These innovations not only optimize energy use but also contribute to improved uptime and reliability, as predictive maintenance minimizes unexpected breakdowns.

Additionally, connected equipment enables data-driven decision-making, allowing operators to fine-tune performance and extend the life span of critical machinery. This holistic strategy supports sustainable operations while maximizing productivity and cost-effectiveness.

How companies leverage smart asset management for energy efficiency

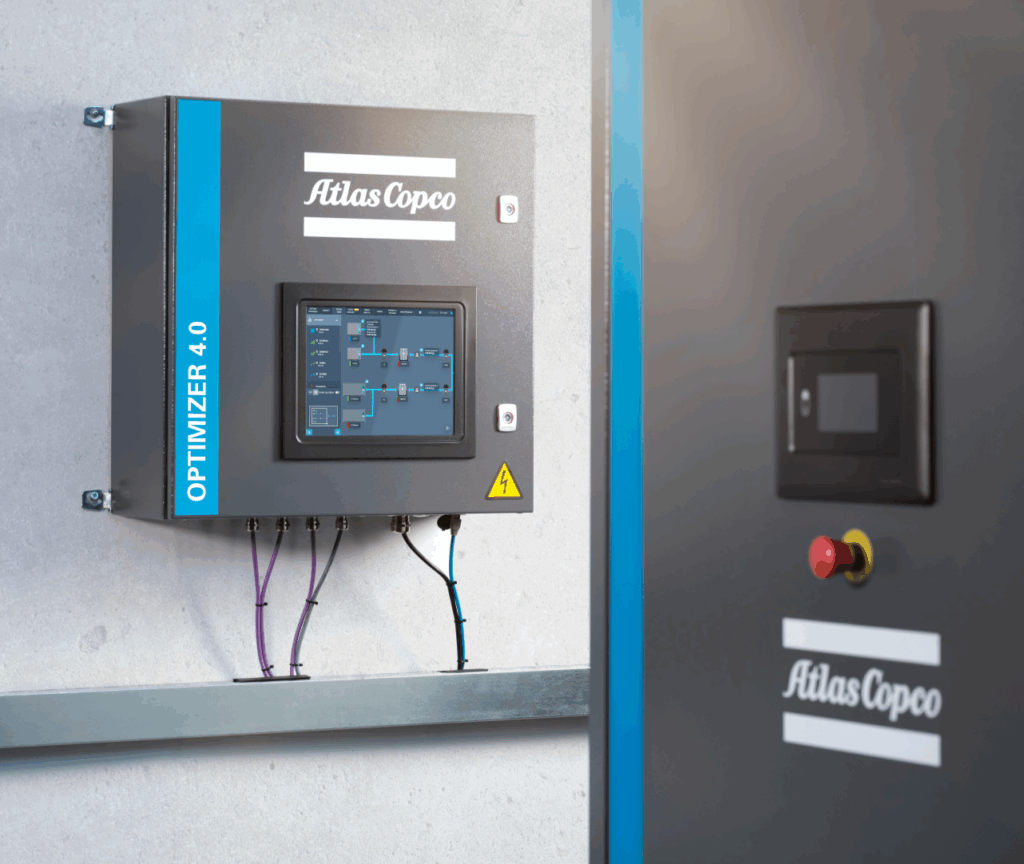

Various companies across diverse industries have successfully leveraged compressor asset management technologies to enhance energy efficiency and operational performance. For instance, a glass ceramics manufacturer optimized its compressor room using Atlas Copco’s Optimizer 4.0 system. This centralized control platform allowed the company to balance compressor loads more effectively, reduce idle running and fine-tune pressure settings. As a result, the manufacturer achieved annual energy savings of approximately $39,000, demonstrating how intelligent control systems can deliver immediate financial returns.

In the fast-moving consumer goods sector, another company conducted a comprehensive system audit. By identifying inefficiencies in compressor sizing and pressure settings and implementing targeted upgrades, the company realized $23,000 in yearly energy savings. These improvements not only reduced operational costs but also enhanced system reliability and lowered the risk of unplanned downtime, which is critical in a sector where production continuity is essential.

A cardboard packaging company also achieved a 20% reduction in energy use through a combination of leak detection, system redesign and the integration of VSD compressors.

Similarly, a food manufacturer implemented a heat recovery system that captured waste heat from compressors and redirected it to support boiler operations. This innovation significantly reduced both energy costs and carbon emissions, aligning with the company’s sustainability goals.

Meanwhile, a South American bearing manufacturer adopted a holistic asset management strategy that included compressor monitoring and predictive maintenance. The result was an 18% reduction in energy consumption and a carbon footprint reduction of 263 tons of carbon dioxide equivalent, underscoring the environmental and economic impact of smart compressor management. Whether through centralized control, predictive analytics or energy recovery, companies are achieving measurable improvements in efficiency, sustainability and profitability.

Technologies enabling smart asset management in compressed air systems

Smart asset management tools are designed to reduce energy consumption, enhance equipment reliability and streamline maintenance operations through automation and data-driven insights. One key innovation is the use of remote monitoring platforms that connect air compressors and related equipment to the cloud. These systems provide real-time visibility into performance metrics such as pressure, temperature and power consumption.

By enabling continuous monitoring, companies can generate performance reports, receive automated alerts for anomalies and schedule maintenance proactively thus preventing small issues from turning into costly downtime.

Some platforms are modular, offering features such as service tracking, energy reporting and uptime analytics. These capabilities allow operators to optimize system performance under real-world conditions and make informed decisions about servicing and upgrades.

Many industrial firms are adopting centralized asset tracking platforms. These systems give organizations the ability to monitor equipment location, status and history, which can be especially important for facilities with assets distributed across multiple sites. Centralized tracking supports life cycle management, regulatory compliance, such as the International Organization for Standardization’s ISO 50001 and predictive maintenance, reducing operational disruptions and extending the lifespan of critical machinery.

Another area of advancement is the integration of artificial intelligence (AI) and machine learning into diagnostic systems. AI-powered analytics can detect abnormal behavior in compressors such as changes in vibration, oil quality or thermal performance long before a failure occurs. These tools help maintenance teams prevent breakdowns and extend equipment life. Some systems also include real-time air quality monitoring in accordance with ISO 8573-1 standards, alerting operators to deviations and offering actionable guidance.

Cloud-based asset management platforms further enhance visibility and control by consolidating performance data, maintenance history and predictive alerts into a single interface. This allows for more strategic planning, timely interventions and better alignment with energy and sustainability goals.

To support mobile workforces, companies are also turning to smartphone apps that provide production insights, quality metrics and predictive alerts directly to operators and engineers. These apps enable faster decision-making and reduce response times when problems arise on the shop floor. In high-precision environments, this real-time responsiveness helps maintain product quality, reduce scrap and optimize throughput.

Overall, by adopting these smart asset management technologies, companies are not only improving operational performance but also taking major strides toward greater energy efficiency.

Two ways to improve air compressor energy efficiency

There are two best practices for bolstering energy efficiency in air compressors.

Routine energy audits: Conducting routine energy audits is one of the most effective ways to identify inefficiencies and uncover opportunities for improvement in compressed air systems. Many air compressor manufacturers offer comprehensive audit tools to help evaluate the entire compressed air network from generation to distribution. These audits help detect leaks, pressure drops and improper equipment size, all of which can lead to significant energy waste. By routinely assessing system performance, companies can implement targeted upgrades and operational changes that reduce energy consumption and improve overall efficiency.

Asset management training: Training staff in asset management tools and technologies is another must when it comes to improving energy efficiency in air compressors. Emphasizing the importance of empowering operators and maintenance teams with the knowledge to use monitoring platforms. These tools provide real-time insights into compressor performance, maintenance needs and energy usage. When staff are well-versed in interpreting this data, they can respond quickly to anomalies, schedule preventive maintenance and make informed decisions that enhance system reliability and uptime.

The benefits of improved air compressors are clear – reduced energy costs, lower carbon emissions, improved uptime and longer equipment life. Real-world case studies show that organizations across sectors are already achieving measurable results by adopting remote monitoring technologies and by following best practices such as regular energy audits and KPI tracking. These strategies not only improve operational performance but also align with broader goals like ISO 50001 compliance and long-term ROI.

Start by assessing a plant’s current compressed air system, identify inefficiencies, evaluate maintenance practices and explore the digital tools available to support smarter asset management. With the right approach, air compressors can become a cornerstone of an energy efficiency success story.