In an October 30, 2023, webcast “Motors and drives: How to optimize industrial energy use,” Michael Lyda from Advanced Energy specifies and analyzes how to optimize energy use for motors and drives and other factors to consider.

Motor and drive insights

- Motors and drives can run for a very long time and keep a plant efficient, but it needs the right equipment and knowledge behind it.

- Understanding the codes and standards behind motors and drives can help engineers enormously in maintaining their equipment.

Over their operating lives, most ac induction motors exhibit common problems, from transients to voltage imbalances and single phasing.

Therefore, being familiar with general troubleshooting techniques is important. To start, it’s vital to understand the operating parameters and forces acting against a motor; to perform tests and make observations based on those parameters; and to remove system components to isolate a problem.

Proper size and power source connection must be verified. Regular measurement procedures, starting with nominal voltage, current and frequency can be the starting point for long-running optimal motor and drive operation.

In an October 30, 2023, webcast, Michael Lyda from Advanced Energy analyzed how to optimize energy use for motors and drives and other factors to consider.

The transcript of this presentation has been provided with minor edits and adaptions for clarity.

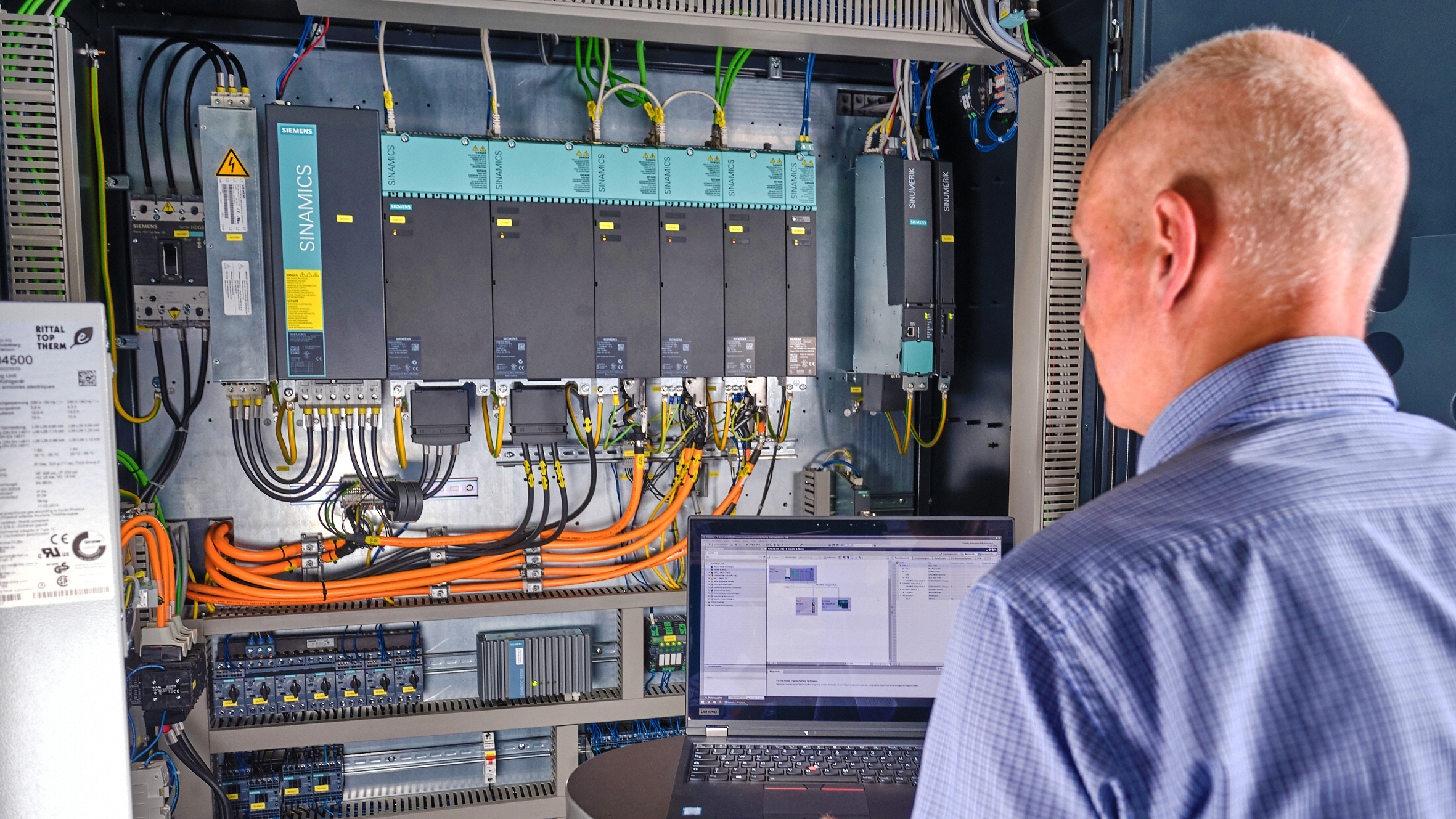

Michael Lyda: What does a VFD drive do? It takes in three-phase power. It can also take in single-phase power. You have single-phase drives, as well, but most of the ones that you’re going to be working with take in three-phase ac power, convert it to dc and then stores that on a dc bus and then converts that power back to ac power through the form of a pulse width modulated signal or pulse width modulator (PWM) signal. The way it does that is through an ac-to-dc rectifier on the front side, on the grid side of things and then a dc-to-ac inverter on the backside with that dc bus in between the rectifier and inverter.

VFDs drives use IGBTs, which are insulated gait bipolar transistors, for the fast switching capability. Sometimes when you go into a facility or you’re walking around a new chiller or something and you start hearing some high-pitched audible noise, it’s likely that maybe there’s some drives that are being used in that facility or maybe there’s some drives on the feed water pumps or the pumps on your chiller. It’s typically very noticeable when you walk in, the sound is coming out of the motor but it’s because it’s being controlled with a variable-speed drive.

The IGBTs are basically turning off and on very fast in the realm of 2,000 to even some modern drives today could do 20,000 times per second, two or 20 kilohertz off and on the IGBTs. The faster rate that they’re turning off and on, the cleaner signal that the motor is going to be seeing. The drive is simulating an ac waveform, but it’s really a square wave, a pulse width modulated signal or square wave. And this is my diagram. Obviously, not all drives these days are like this, but most of the basic ones are.

What are some suitable applications for VFDs? Centrifugal loads, so pumps fans and blowers are very ripe for adding VFDs drives, throttle flow processes and variable processes. And these days new air compressors are very popular VFD applications. Of course, with the air compressors it’s not typically something you can retrofit. If you take an old air compressor, you can’t just put a VFD on the compressor and then it’s going to operate. It needs to be a certain type of compressor. If you’re looking at VFD air compressors, you likely need to buy a new one. That’s an all-in-one package. Screw compressors are good. Typically, VFD compressors, the screw compressors are going to be a good fit for those.

Boiler, chiller feed water pumps, RO feed water pumps, anything like that, good opportunities. Fans, everywhere, exhaust fans, return fans, supply fans from your HVAC units. If the units don’t come with those already, they’re typically good applications. And then these last two items will be specific to your facility, high operating hours. And what does that mean? Well maybe if you have a 24/7 facility, you’re running over 8,000 hours a year, then if you have a lot of your utilities running constantly, then you’re going to have a lot of equipment with high operating hours and the higher the operating hours, the more time you have to capture the energy savings and offset the cost of the drive, the capital investment cost.

And then, in addition to the operating hours, also look at larger motors. Here I put an example, 75 HP, but the larger it is, if it’s running at high operating hours, then it’s going to allow for quicker payback to offset that capital investment. Once you’ve identified the applicants for using your VFDs drives, you may need to dig a little bit deeper to determine the best candidates. If you’ve done a motor management survey or built a database of your motors, maybe you’ve captured what the run hours are or you’ve captured the running currents, things like that. If not, you’ll need to go through and gather that information.

If there’s an equipment operator or the facility’s maintenance person, if you’re not that person, definitely go do an interview with them and learn more about which applicant, which motors you should be looking at. And then once you have those run hours estimated or exact run hours, what I would recommend is, say, if you’re a 24/7/365 facility, I would say look at all centrifugal loads with over 6,000 hours of annual usage. Maybe you don’t run as much if you’re a five-day-a-week facility. Maybe you want to focus on 4,000 run hours as a start or something like that. It really just depends on your facility as to what your definition of high run hours and what your definition of a large motor is.

Next we have three different applications. One, we’re going to start with a poor candidate, then we’ll go to good candidate, then we’ll go to an excellent candidate and look at the load profiles of these different applications and you could hopefully take this example back to your facility and match it with some of your own applications. This one is a very highly loaded application. Why shouldn’t we add a variable frequency drive to high loaded applications? That’s because the VFD itself does use energy so if you put a VFD on a motor and the motor is running near full load, you just add unnecessary power to the circuit and actually you’re going to raise the electricity usage, the electricity to power the VFD itself so adding A VFD doesn’t make sense in this case.

On the next example, we have a moderately loaded application. So most of the operating time is spent around 70% loads. It looks like 60% to 70% load. This presents a great opportunity to slow the motor by adding a variable-speed drive and capture some energy savings based on the affinity loss. If we can slow it down, then we can use less energy. Then finally, the third example, you notice the difference would say number two and number three. We have the moderately to low loaded application. Some loading starting at 40% up at 40, quite a bit at 55%, 60%, and then only a little bit above 70%.

This is an excellent candidate for adding VFD drive and definitely presents a great opportunity for significant energy savings. Likely, if you looked in your facility and you found a motor like this, it’s likely oversized for the application. You could consider, do I want to match the motor more appropriate to the application or do I want to add a variable-speed drive? Adding the speed drive, it still gives you that top-end torque requirement if you need it, if you ever need to run it 100% for short periods of time, but then it’s going to give you a lot of energy savings below that 80 or 70% loaded.