The market for planetary precision gearboxes is forecast to expand significantly, driven by high levels of demand within the mobile robots segment.

Mobile robots insights

- Mobile robots are helping drive the precision gear market, which is expected to reach $5 billion by 2027.

- The market itself may seem somewhat consolidated, but there is plenty of potential growth in the software.

The mobile robots segment is growing rapidly and is forecast to become the leading industry for sales of planetary precision gear products by 2026, according to our analysis of the precision gear products market.

Precision gearboxes are designed to have low or zero backlash, meaning the clearance between interlocking teeth is much smaller than in standard gearboxes. They are designed to be attached to servo motors and used wherever fast, precise motion is needed. Hence, the markets for precision gearboxes and motion controls systems are closely related.

What is driving precision gear product growth?

Precision gearboxes and geared motors have seen considerable growth over the past couple of years. We estimate the market for precision gear products grew by 17% from 2021 to 2022. By 2027, this market will grow to over $5 billion, albeit at a slower rate than that of the past couple of years.

As an important component within a motion control system, demand for precision gearboxes and geared motors has been boosted by increased automation and use of robotics within the manufacturing sector, where concerns about labour shortages and potential future supply chain issues resulted in high volumes of orders, combined with multiple price increases resulting from global economic uncertainty.

Three types of precision gears

Precision gearboxes can be classified into three main types:

-

Planetary

-

Strain wave

-

Cycloidal.

Over the last year, the markets for strain wave and cycloidal solutions have grown faster than their planetary counterparts, owing to their greater use in articulated and collaborative robots, which have seen high levels of demand. While strain wave and cycloidal gearboxes – having the lowest backlash ratings – are most often employed within industrial robots, precision planetary gearboxes can be found in a variety of industries and applications, including the fast-growing mobile robots segment.

Planetary design dominates the precision gear market

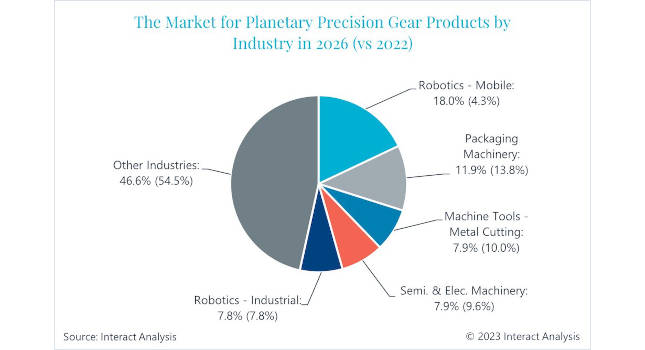

Just under 50% of precision gear products sold in 2022 had a planetary design, with packaging machinery as the leading market for planetary gear products over the year, accounting for 14% of global sales. This was followed by metal cutting machine tools, semiconductors and electronics machinery, materials handling, and industrial robots (mainly delta robots), and there was little between each of the leading markets in 2022, demonstrating the wide range of applications for planetary precision gears.

We predict the market for planetary precision gears will change substantially between 2022 and 2026, with mobile robots surging ahead to account for 18% of products sold by 2026 (up from 4.3% in 2022). The chart below shows how the mobile robots segment is expected to overtake packaging machinery over the 4 year period, with 2022 data in brackets for comparison.

Packaging machinery is currently the largest market for planetary gear products, but mobile robots is the fastest-growing.

In contrast, planetary gear sales are not expected to grow by more than 5% year-on-year in other industries, making mobile robots the fastest-growing market segment by far, with a predicted CAGR of 55% for 2022-26.

The huge growth within the mobile robots sector is driven by an increasing demand for warehouse automation, following the fallout from the COVID-19 pandemic, which led to a boom in e-commerce. From visiting trade shows such as Hannover, Automatica and SPS, it’s clear many suppliers are developing components targeting the mobile robots market. We anticipate the vast majority of mobile robots employing precision gear products will have planetary gears (~95%). There are very small amounts forecast to be fitted with strain wave or cycloidal technology, as mobile robots do not require the ultra-high precision for positioning and moving that they offer.

Market not as consolidated as it appears

Precision planetary gear products appears at first glance to be a consolidated market. Wittenstein was the top global producer of precision planetary gear products in 2021, with around 25% of product sales, and the next largest suppliers were Neugart, Nidec Shimpo, Apex Dynamics and Stöber. Together, these 5 companies represented 56% of the global market and were followed by a long tail of suppliers, mainly based in Europe and China, commanding smaller market shares. While new suppliers pop up in China, they are not expected to have a substantial impact on the top 5, with the largest companies expected to continue to dominate the market for the foreseeable future.

However, our discussions with various suppliers from across the industry have revealed the growing importance of digitalization within industrial automation, and this is also true for precision gearboxes. By attaching sensors in order to measure parameters like temperature and vibration, and creating a real-time model using digital twin software, the current state of the gearbox can be closely monitored, and potential future failures predicted and resolved before any fault can occur.

Therefore, perhaps it is in developing the accompanying software, rather than hardware, where new suppliers can break into this market and start challenging the top industry players. It may well be that in the future we see smaller companies break through as a result of this increasing trend towards digitalization.

– Interact Analysis is a CFE Media and Technology content partner. Edited by Chris Vavra, web content manager, Control Engineering, CFE Media and Technology, [email protected].