When electricity was cheap, efficiency was not necessarily top of mind for many. However, current energy prices force manufacturers to further analyze where they use energy and how they spend their energy dollars. According to NEMA, electric motor and generator driven systems account for nearly 70% of the electricity consumed in the U.

When electricity was cheap, efficiency was not necessarily top of mind for many. However, current energy prices force manufacturers to further analyze where they use energy and how they spend their energy dollars.

According to NEMA, electric motor and generator driven systems account for nearly 70% of the electricity consumed in the U.S. industrial manufacturing sector. Thanks to leading motor manufacturers and groups such as Motor Decisions Matter, manufacturers are beginning to replace motors with NEMA Premium motors, improve rewind practices and follow U.S. Department of Energy and Electrical Apparatus Service Association best practices.

However, some manufacturers are still using EPAct and pre-EPAct motors. Some manufacturers and OEMs are still applying larger motors than loads require, which is extremely inefficient. Some are still starting motors that could be used with soft starters or adjustable speed drives across the ac line.

These 7.5 hp motors are driving hydraulic pumps on automated winders in an Emerson Motor Co. plant.

Too large for the load

Many of the motors in operation today in the U.S. are larger than they have to be. Many motors are loaded at less than 50%. However, they use almost as much electricity at lighter loads as they do fully loaded — an expensive mode of operation. Appropriately matching the motor and its load produces savings that add directly to the bottom line.

Tim Albers, director of marketing, Emerson Motor Co., St. Louis described a scenario where a facility wanted to upgrade to Premium Efficiency motors. According to Albers, many of their motors had been there 30 to 40 years. “More than half of their motors were 50% loaded or less. In many cases, the actual load on the belt was 15 hp — and they were using a 50 hp motor!”

For this application, Albers explained a 20-hp motor provides a 25% safety factor; 25 hp provides a 40% safety factor. “Do they think they need more than 40%? No, they had a 150% safety factor on this motor!”

Motors designed into original equipment are typically ‘right sized’ if the OEM is following best practices. Albers said companies such as Ingersoll Rand, ITT Goulds and Flowserve have the tools in place to do an appropriate job. “When ITT Goulds or Flowserve is sizing a pump motor, or Ingersoll Rand is sizing a compressor motor, they understand that they’re sizing motors between 75% or 80% to 105% of rated horsepower. They know exactly what they’re doing. They know whether they need the extra safety factor or not. They know the questions to ask to get a correctly sized product,” Albers said.

Equipment manufacturers supply torque characteristics for given loads, such as these typical pump curves. Motor manufacturers supply torque characteristics for the motors they manufacture. Appropriately matching motor and load requires this information.

“The biggest issue we run into is when people who are not experienced try to size a motor or choose a motor for an application,” Albers continued. “The biggest issue is either smaller manufacturers or end-user maintenance personnel who say ‘I had a 40 hp, it failed, why don’t I put a 50 hp on this time?’ That 40 hp (motor) might have lasted 12 or 14 years, which is an appropriate life of the motor. Upsizing the motor may or may not be a good thing. For efficiency, it’s probably a bad thing.”

Not all end users fall into the inefficient category. “The same thing I said about the large OEMs is also true about the large end users,” Albers said. “There are guys who have written papers about efficiency in their operation; they know exactly what’s going on. They are sizing them — because they know that as long as they are at 70% loading or more, they are getting the full efficiency of the product — and they know exactly where they are going with it.”

Right-size the motor for the load

“Reduce system load,” said John Malinowski, product manager, ac and dc motors, at Baldor Motors and Drives, speaking at the Plant Engineering Manufacturing Summit in Chicago. “In the U. S., we always think bigger is better. Well, it isn’t. You need the right size. Motor downsizing is on the DOE list. I don’t like calling it ‘downsizing;’ I like to call it ‘right-sizing.’”

“Match the equipment to the load,” continued Malinowski. “Something as simple as going to one of these notched V-belts, instead of a solid V-belt, can add 3% to system efficiency.”

To optimize efficiency, determine whether the specific torque capabilities of a motor meet the torque requirements of the application’s load. Although motors that operate with constant flux are said to have constant torque, the demand of the load determines the actual amount of torque produced. Compare the motor’s speed-torque curve with the load’s speed-torque requirements.

Motor manufacturers supply torque characteristics for the motors they manufacture. NEMA’s publication MG 1 is another good source for this information. The most accurate way to obtain torque characteristics of a given load is to obtain them from the equipment manufacturer.

These motors are driving natural gas compressors used to compress gas from a pipeline prior to injection into a peak power gas turbine power station in Montreal.

Malinowski said the sweet spot for an ac induction motor is between 75% and 100% efficiency. “If you size all the motors for the plant, (you should) size a motor for about 80% of the load. That’s absolutely the efficiency peak on a typical ac induction motor. If you have a motor that runs at lighter loads, the efficiency drops off, but the power factor drops off really significantly, so that 75% to 100% is really the right-rated load point,” he said.

Malinowski recommends using current measurements as part of a Level 2 motor survey to determine if the correct motor is applied. He said using the right size motor for an application increases efficiency and power factor, as well as the purchase price. “While you’re doing the survey, this is a point where you may also consider adding the adjustable speed drive,” he said.

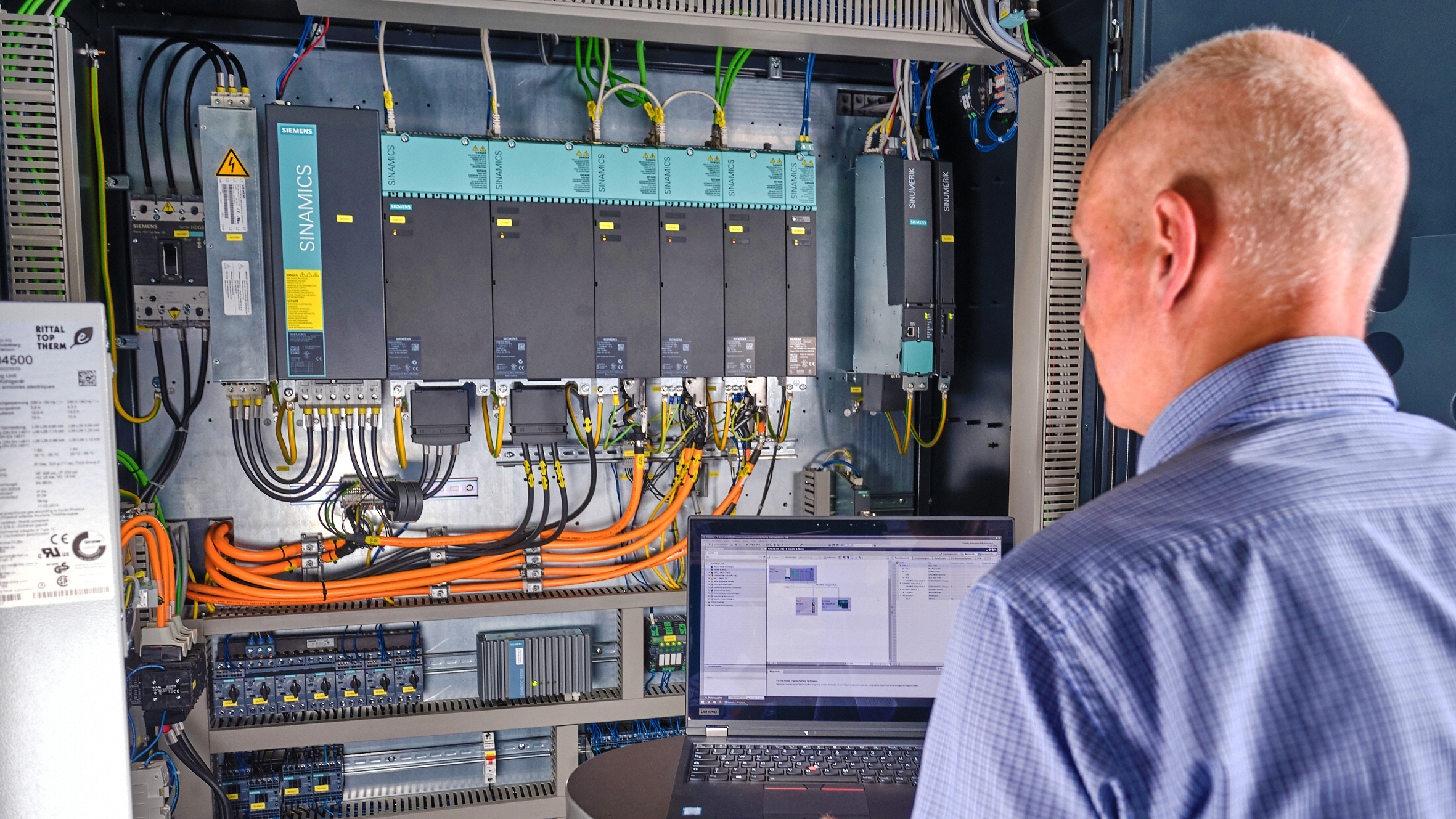

Consider adjustable speed drives

Adjustable speed drives can greatly increase applied motor efficiency. ASDs enable induction motors to start up and operate using less current. Inrush current for typical pre-EPAct motors started across the line can be 5 to 6 times the running current of the motor. Inrush can be 6.5 to 7 times more for EPAct motors, and as much as 8 times for Premium Efficiency motors, which is one of their tradeoffs.

Using ASDs on variable torque loads such as pumps, fans and compressors produce enormous savings said Malinowski, describing Level 3 plant surveys. “Now, you’re really getting into some heavy engineering. You’re going to look at the whole system. Look beyond the motor. Add adjustable speed drives on pumps and fans. The process control can also help you increase productivity,” he said.

When selecting a motor for use with an ASD (also called variable-speed drive), consider the application, load characteristics, speed range, environment and drive requirements.

In an article published in the July 2002 issue of Plant Engineering titled “How to match ac motors and variable speed drives,” the authors wrote:

“Regarding torque characteristics, the majority of variable-speed ac drive applications fall into either variable torque or constant torque applications. Centrifugal pumps and fans are variable torque applications where most fixed-speed, energy efficient ac motors can be used without concern of overheating. The horsepower required to operate centrifugal pumps and fans decreases with the cube of the speed. That means if you reduce the speed of the ac motor to one-half of base speed, the horsepower required is only one-eighth of rated horsepower.”

These motors are driving blowers in a chlorine-free pulping process at a paper mill.

Malinowski used a typical pump application to further describe this relationship. With a typical pump running with a bypass valve, if the amount of flow changes from 100% to 40%, the kilowatts needed to operate the motor in the pump system don’t change. “If I put a throttle valve in there and vary the flow, it changes a little bit. But if I get rid of the valves — or the dampers in an HVAC system — and control the flow by changing the speed of the motor, between 100% flow and 40% flow, I’ve gone from 85 kW down to about 12 kW. The more we run at the lighter, lower flows, the more energy we’re going to save.”

Don’t forget maintenance

When replacing a failed motor, upsizing horsepower is not among the maintenance best practices. However, taking good care of installed equipment is. “When you see something operating out of the normal trend, check it out,” said Malinowski. “Find out what’s binding it up, causing it to draw more current.”

Maintenance best practices also include establishing a Motor Management program. Motor Decisions Matter established guidelines that can streamline the process. According to Malinowski, MDM’s Level 1 involves surveying the facility to take inventory of all the motors. “Tag each motor as to what to do when it fails,” he said. “Undoubtedly, it’s going to fail on the third shift or on a Sunday afternoon when one of the newer maintenance people is on duty. You don’t want him deciding on his own what motor goes in there. He’s just going to get the (equipment) up and running. It may be an oversized motor or an inefficient motor for what the job is. You’re not going to change it because it’s running, so you’re stuck with it until it fails again. Tag the motors so that whoever is doing the maintenance knows what to do.”