The three most expensive items in operating a compressed air system are inadequate, inefficient controls that waste energy, costly lost production due to an improperly maintained system, and leaks. State-of-the-art controls can provide efficient volume and pressure regulation of compressed air delivery and signal when maintenance or repair is due.

|

The three most expensive items in operating a compressed air system are inadequate, inefficient controls that waste energy, costly lost production due to an improperly maintained system, and leaks. State-of-the-art controls can provide efficient volume and pressure regulation of compressed air delivery and signal when maintenance or repair is due.

Energy savings of 15-20% and long term maintenance savings of 7-10% are common for advanced control systems compared to conventional electropneumatic controls.

The goal of a compressed air system is to use the least amount of air at the lowest quality and pressure that satisfies system requirements. Individual air compressors with their own controls can accomplish this, but multiple installations without a central control cannot operate at maximum possible efficiency.

There are three main types of industrial air compressors: reciprocating, rotary screw, and centrifugal. Each type requires unique controls to operate efficiently and prevent failure.

Regardless of the compressor technology or capacity, multiple compressor installations tend to operate more efficiently and economically when using multiple-compressor control systems (Fig. 1). Compressors are operated efficiently when at full load. To handle swings in load demand, one or more smaller units are regulated to handle air demand variations.

Fig. 1. Compressors linked to a multiple control operate efficiently.

Use and misuse of energy by conventional compressor controls occurs in two areas: inadequate pressure control and multicompressor operation with wide, overlapping pressure bands.

Conventional controls on individual compressors are difficult to set up and maintain for adequate response to changing plant air demands. The result often is more compressors operating than are needed.

When several compressors operate in an inefficient part-load condition, one is loading up in response to another unloading. This lack of multicompressor control wastes energy by having more compressor capacity online than needed. This condition results in overpressure in the system with leaks wasting more air.

Compressor controls

The search for cost savings has increased the awareness of the high electrical cost of operating a compressed air system. It takes more than an understanding of controls to correct the problem. There is an interdependent relationship between the components of a compressed air system.

Typically, a plant either adds compressors to handle growth or replaces older units with newer ones. Air system controls must be able to accommodate various types of compressors and their control systems.

Controls should have the ability to control compressor capacity based on a single, target pressure. Depending on the type of compressor and control method, a tunable, pressure control deadband should regulate load/unload cycle times (Fig. 2). Effective use of air storage receivers can enhance control efficiency by supplying load demands and reducing compressor operation.

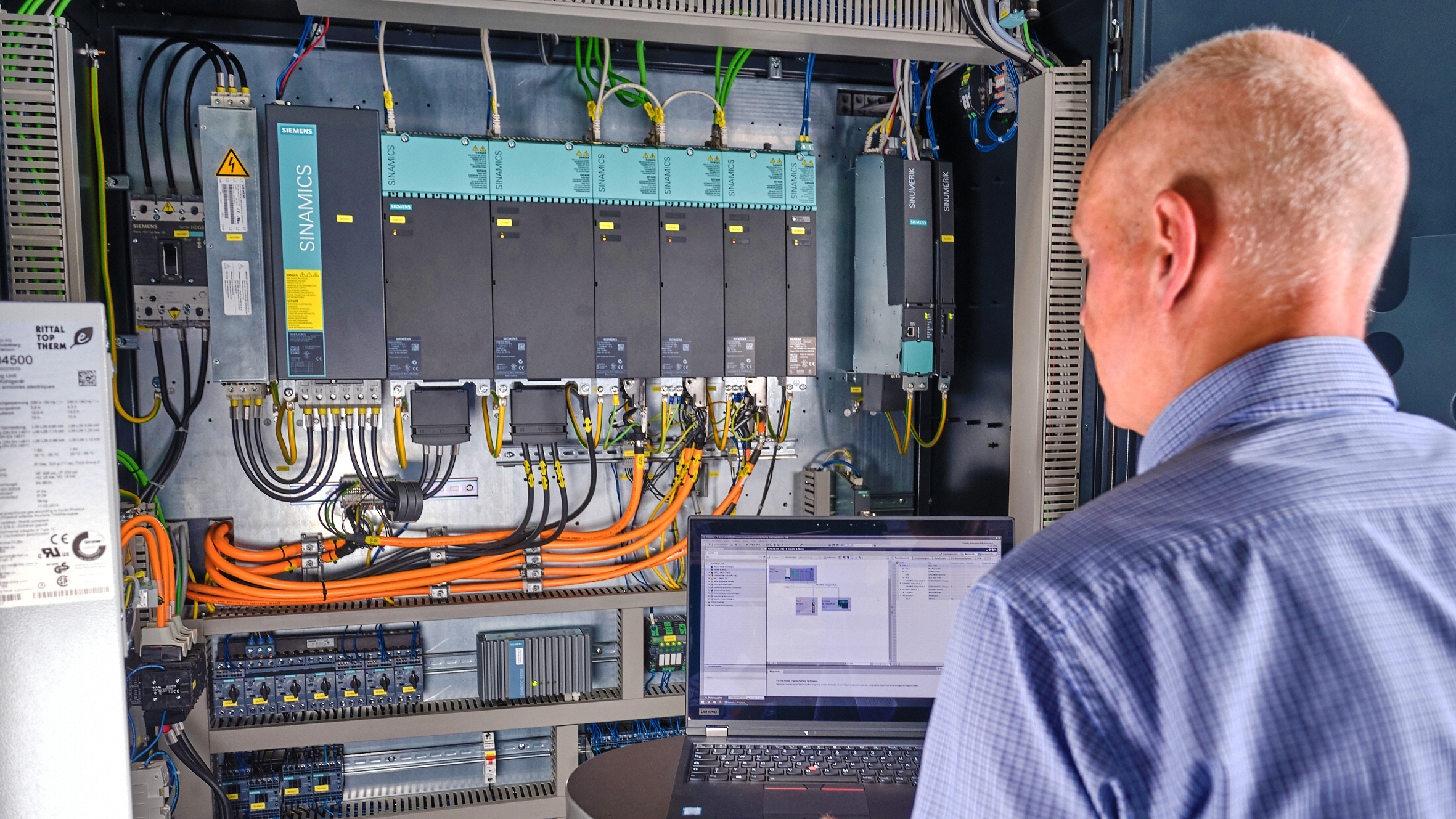

Fig. 2. Multiple compressor control panel provides an overview of compressor status.

A proportional integral derivative (PID) loop control can continuously adjust reactive time, provide good pressure control, and optimize load/unload cycling. This method of control can be applied to all three types of compressors.

Electro-pneumatic controllers allow the control pressure to have a range as low as 5 psig with moderate accuracy. A cascading system results in a high pressure band, increasing energy consumption. This system is capital-cost effective and the control span is somewhat increased, but provides a moderate level of energy savings. However, this system does not provide much flexibility for compressor sequencing.

PLC controllers use a common, accurate pressure transducer and control which allows the pressure range to be as low as 2 psig consistently. Since the system operates all compressors in a common pressure control range, pressure fluctuations are reduced and energy is saved. While the sequence rotation is better than that of electropneumatic units, it is usually limited to a fixed sequence.

Microprocessor controllers also can maintain a narrow pressure range of 2 psig. This design offers the ability to program the controller for a variety of sequences to suit the application. Communication capability and service and preventive maintenance information is built-in.

Features can include a constant readout of pressure and temperature, on-demand readout of all operating and maintenance conditions, monitoring of key functions and safety shutdowns, and power failure auto restart.

Reciprocating compressors

Double-acting, reciprocating compressors are essentially constant-capacity and variable-pressure machines. Their output can be varied by start/stop up to 10 hp, load/unload, and capacity controls. The first two methods are straightforward; they simply start and stop a motor or vent the output when the upper pressure limit is reached.

There are three types of capacity control. One type involves holding the inlet valves open, resulting in no air being compressed. Another type employs clearance pockets. If a clearance pocket is opened, the volume of the cylinder is increased, reducing the compression ratio. The third type of mechanism used on two-stage, double-acting compressors involves closing off the supply of air to the first stage and venting the second stage to atmosphere.

Rotary screw compressors

Fig. 3. Inlet valves and turn valves control rotary screw compressor capacity.

Rotary screw compressor pressure/capacity control is accomplished by inlet throttling or modulation, rotor length control or variable displacement (Fig. 3), and speed control.

Modulation restricts the inlet opening to admit only the amount of air demand by the system. With system inefficiencies, more energy is expanded per cu ft of air compressed. This system should be used for base load applications where system needs don’t go below 70%.

Variable displacement controls air output by varying the length of rotor compression as demand for air declines. Unneeded air returns to the inlet before being compressed. This method is an efficient control system for part-load applications above a 40% load cycle.

Variable speed control varies the speed of the drive motor and the airend, thus controlling output. It outperforms all other forms of capacity control. The efficiency of a given size and design of airend is governed, in part, by the tip speed of the rotors. Efficiency remains relatively constant through a range of speeds, but falls off dramatically if the airend operates out of its range. Contact the compressor manufacturer before retrofitting to a variable speed drive.

Centrifugal compressors

Centrifugal compressors have a limited throttling range due to the potentially damaging event called surge. Surge characteristics vary with changes in discharge air pressure, intake air temperature, inlet air pressure, cooling water, and relative humidity. Control systems compensate for these changes, maximizing the throttle range and minimizing wasteful blowoff.

Two common ways to reduce the capacity of a centrifugal air compressor are restricting the intake with a butterfly valve or adjustable inlet guide vanes (IGV), and varying the speed. If both are incorporated in one package, ultimate control can be achieved, at a price.

Fig. 4. Centrifugal compressor inlet guide vane control provides 40% turndown at constant pressure.

Inlet control is a relatively low-cost way to control capacity. It can provide a nominal turndown of about 40% at ambient conditions of 95 F and 60% relative humidity (Fig. 4). Any deviation from these conditions affects the turndown. The colder the inlet air temperature, the greater the turndown.

Fig. 5. Centrifugal compressor speed control provides 30% turndown at constant pressure.

Capacity control by varying the drive motor speed provides a turndown of about 30% (Fig. 5). If the compressor is to operate above base speeds, check the drive motor’s ampere limit against the manufacturer’s aerodynamic performance curve to determine if the motor is large enough.

Compressor protection

While energy efficiency is the most measurable advantage of modern compressor controls, condition monitoring and lower maintenance costs extend the useful life of a compressor and reduce downtime.

Condition monitoring provides vital information for preventive maintenance of dirty inlet air filters, fouled interstage coolers, and excessive wear of components. By monitoring and trending key parameters such as inlet and interstage pressures and compressed air temperatures, preventive rather than emergency maintenance can be done.

Some troubleshooting messages from a microprocessor controller

| Message | Probable cause | Remedy |

| Air Filter Maintenance | Pressure across inlet filter high | Replace filter. Check inlet filter pressure switch. |

| Aux. Motor Overload | Motor tripped on cooling fan, oil pump, or other motor | Reset auxiliary overload after heater element cools. Check motor starter contact for proper operation. Check for low line voltage. |

| Low Water Pressure | Cooling water pressure below limit | Check for closed valves or broken pipes. |

| Oil Filter Maintenance | Pressure across oil filter too high | Oil filter clogged, replace. Sensor failure, check sensor, wiring, and tubing. |

| Acknowledgements | ||

| Plant Engineering magazine extends its appreciation to Cooper Turbocompressor for its assistance in the preparation of this article and in providing the cover photo. We would also like to thank Atlas Copco Compressors, Inc.; Compare; Gardner Denver; Kaeser Compressors, Inc.; Ingersoll-Rand Co., Air Compressor Group; Sullair Corp.; and Quincy Compressor for their assistance in the preparation of this article. | ||

Six basic compressor controls

Start/Stop starts and stops the motor driving the compressor in response to a pressure signal. The use of start/stop operation is limited to the amount of heat the motor can stand from inrush current. (For reciprocating and rotary screw)

Load/Unload allows the motor to run continuously, but unloads the compressor when a predetermined upper pressure limit is reached. The compressor reloads at a predetermined lower discharge pressure. Also known as constant speed or constant run control. (For reciprocating, rotary screw, and centrifugal)

Modulation restricts inlet air to the compressors to reduce compressor output to a specified minimum. Also known as throttling or capacity control. (For rotary screw and centrifugal)

Dual/Auto Dual controls for small reciprocating compressors, allow the selection of start/stop or load/unload. For lubricated rotary screw compressors, dual/auto dual controls provide modulation to a preset reduced capacity followed by unloading. An overrun timer stops the compressor after running unloaded for a preset time.

Variable Displacement allows progressive reduction of compressor displacement without reducing the inlet pressure. (For reciprocating, multi-step, and rotary screw with rotor length adjustment)

Variable Speed adjusts compressor capacity by varying the speed of the electric motor in response to system signals. (For rotary screw and centrifugal)

Reduce compressed energy costs

The U.S. Department of Energy (DOE), with technical support from the Compressed Air Challenge, recently created an assessment of the market for compressed air efficiency. The assessment provides a comprehensive view of the market for consulting services to improve the energy efficiency of plant compressed air systems. These services include plant assessments to identify improvement opportunities for compressed air systems, preventive maintenance services, and redesign of system components to reduce energy use.

According to DOE, compressed air systems account for 10% of all electricity and roughly 16% of U.S. industrial motor system energy use. About 70% of all manufacturing facilities in the U.S. use compressed air to drive a variety of equipment.

More than half of all industrial plant air systems have the potential for substantial energy savings with relatively low investment costs. In small to medium-size industrial facilities, 15% of compressed air usage can be saved with simple paybacks of less than 2 yr. In larger facilities, these savings can range from 30% to 60%.

In addition to energy benefits, optimized compressed air systems frequently offer improvements in system reliability, product quality, and overall productivity.

Reduce compressed energy costs

The U.S. Department of Energy (DOE), with technical support from the Compressed Air Challenge, recently created an assessment of the market for compressed air efficiency. The assessment provides a comprehensive view of the market for consulting services to improve the energy efficiency of plant compressed air systems. These services include plant assessments to identify improvement opportunities for compressed air systems, preventive maintenance services, and redesign of system components to reduce energy use.

According to DOE, compressed air systems account for 10% of all electricity and roughly 16% of U.S. industrial motor system energy use. About 70% of all manufacturing facilities in the U.S. use compressed air to drive a variety of equipment.

More than half of all industrial plant air systems have the potential for substantial energy savings with relatively low investment costs. In small to medium-size industrial facilities, 15% of compressed air usage can be saved with simple paybacks of less than 2 yr. In larger facilities, these savings can range from 30% to 60%.

In addition to energy benefits, optimized compressed air systems frequently offer improvements in system reliability, product quality, and overall productivity.

Reduce compressed energy costs

The U.S. Department of Energy (DOE), with technical support from the Compressed Air Challenge, recently created an assessment of the market for compressed air efficiency. The assessment provides a comprehensive view of the market for consulting services to improve the energy efficiency of plant compressed air systems. These services include plant assessments to identify improvement opportunities for compressed air systems, preventive maintenance services, and redesign of system components to reduce energy use.

According to DOE, compressed air systems account for 10% of all electricity and roughly 16% of U.S. industrial motor system energy use. About 70% of all manufacturing facilities in the U.S. use compressed air to drive a variety of equipment.

More than half of all industrial plant air systems have the potential for substantial energy savings with relatively low investment costs. In small to medium-size industrial facilities, 15% of compressed air usage can be saved with simple paybacks of less than 2 yr. In larger facilities, these savings can range from 30% to 60%.

In addition to energy benefits, optimized compressed air systems frequently offer improvements in system reliability, product quality, and overall productivity.

Reduce compressed energy costs

The U.S. Department of Energy (DOE), with technical support from the Compressed Air Challenge, recently created an assessment of the market for compressed air efficiency. The assessment provides a comprehensive view of the market for consulting services to improve the energy efficiency of plant compressed air systems. These services include plant assessments to identify improvement opportunities for compressed air systems, preventive maintenance services, and redesign of system components to reduce energy use.

According to DOE, compressed air systems account for 10% of all electricity and roughly 16% of U.S. industrial motor system energy use. About 70% of all manufacturing facilities in the U.S. use compressed air to drive a variety of equipment.

More than half of all industrial plant air systems have the potential for substantial energy savings with relatively low investment costs. In small to medium-size industrial facilities, 15% of compressed air usage can be saved with simple paybacks of less than 2 yr. In larger facilities, these savings can range from 30% to 60%.

In addition to energy benefits, optimized compressed air systems frequently offer improvements in system reliability, product quality, and overall productivity.

Reduce compressed energy costs

The U.S. Department of Energy (DOE), with technical support from the Compressed Air Challenge, recently created an assessment of the market for compressed air efficiency. The assessment provides a comprehensive view of the market for consulting services to improve the energy efficiency of plant compressed air systems. These services include plant assessments to identify improvement opportunities for compressed air systems, preventive maintenance services, and redesign of system components to reduce energy use.

According to DOE, compressed air systems account for 10% of all electricity and roughly 16% of U.S. industrial motor system energy use. About 70% of all manufacturing facilities in the U.S. use compressed air to drive a variety of equipment.

More than half of all industrial plant air systems have the potential for substantial energy savings with relatively low investment costs. In small to medium-size industrial facilities, 15% of compressed air usage can be saved with simple paybacks of less than 2 yr. In larger facilities, these savings can range from 30% to 60%.

In addition to energy benefits, optimized compressed air systems frequently offer improvements in system reliability, product quality, and overall productivity.

Reduce compressed energy costs

The U.S. Department of Energy (DOE), with technical support from the Compressed Air Challenge, recently created an assessment of the market for compressed air efficiency. The assessment provides a comprehensive view of the market for consulting services to improve the energy efficiency of plant compressed air systems. These services include plant assessments to identify improvement opportunities for compressed air systems, preventive maintenance services, and redesign of system components to reduce energy use.

According to DOE, compressed air systems account for 10% of all electricity and roughly 16% of U.S. industrial motor system energy use. About 70% of all manufacturing facilities in the U.S. use compressed air to drive a variety of equipment.

More than half of all industrial plant air systems have the potential for substantial energy savings with relatively low investment costs. In small to medium-size industrial facilities, 15% of compressed air usage can be saved with simple paybacks of less than 2 yr. In larger facilities, these savings can range from 30% to 60%.

In addition to energy benefits, optimized compressed air systems frequently offer improvements in system reliability, product quality, and overall productivity.

Reduce compressed energy costs

The U.S. Department of Energy (DOE), with technical support from the Compressed Air Challenge, recently created an assessment of the market for compressed air efficiency. The assessment provides a comprehensive view of the market for consulting services to improve the energy efficiency of plant compressed air systems. These services include plant assessments to identify improvement opportunities for compressed air systems, preventive maintenance services, and redesign of system components to reduce energy use.

According to DOE, compressed air systems account for 10% of all electricity and roughly 16% of U.S. industrial motor system energy use. About 70% of all manufacturing facilities in the U.S. use compressed air to drive a variety of equipment.

More than half of all industrial plant air systems have the potential for substantial energy savings with relatively low investment costs. In small to medium-size industrial facilities, 15% of compressed air usage can be saved with simple paybacks of less than 2 yr. In larger facilities, these savings can range from 30% to 60%.

In addition to energy benefits, optimized compressed air systems frequently offer improvements in system reliability, product quality, and overall productivity.