December 2013

From packaging to tuning to visualization

Applied Automation covers aspects of the bagging process, PID tuning, and HMI system standardization in the December 2013 issue. » more

Standardizing control room HMIs

Next generation HMIs create an environment where operators and technicians can move at speed of manufacturing and make decisions that increase the bottom line. » more

Top Plant 2013: A spark of excellence

Many factors determine how well a manufacturing plant performs. Those that perform best are qualified to become a Top Plant. » more

Take a risk by challenging ‘conventional wisdom’

Conventional wisdom…is the safest route, the path of least resistance, but it isn’t a path to greater success. It is just an avoidance of possible failure. » more

Top 10 ways to streamline a ‘live factory’ project

When designing a new project, consider these ten tips to evaluate whether you and your A/E are employing best practices » more

Plant Engineering in 2013: The Top 15 online stories

The most-read stories on Plant Engineering for 2013 include stories on motor repair and replace, rolling resistance, and the 2012 Product of the Year award winners » more

To develop Lean culture, first build ‘wildfire engagement’

Building an understanding of Lean manufacturing and showing how it can benefit manufacturers in the short- and long-term is vital » more

Use an FEB to ensure safe installation, operation of electrical equipment

Complying with FEB and NRTL standards are vital to ensuring worker safety and standards for electrical products and systems » more

November 2013

Got a wish list? You’ve come to the right place

Lifecycle management brings in new products, though the basic wants and needs and desires remain the same. » more

A road map to reliability

How Premier Silica’s Brady operation used evaluation to improve plant performance. » more

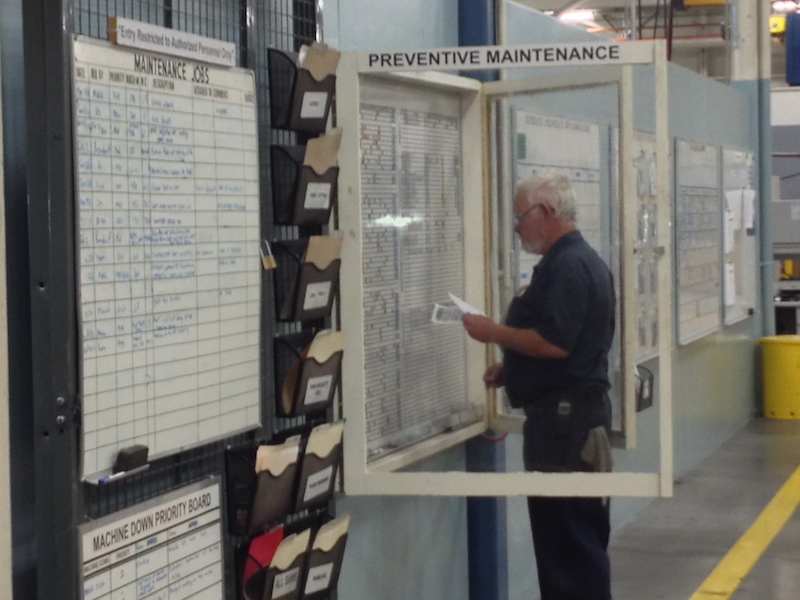

Maintenance must take lead in machine guarding checks

In a letter to the editor, Chris Mumford from ManagerPlus argues that establishing a thorough preventive maintenance checklist is vital to improve safety. » more

Finding the hidden value in asset hierarchy validation

Make the effort now to save time and money down the line. » more

Six strategies to mitigate arc flash incidents

From analysis to equipment; you can reduce the exposure to a dangerous event » more

VFDs: The path to prolonged life

Proper maintenance and attention to detail can stretch productivity » more

Wireless M2M increases value of wired infrastructure

New technology overcomes limitations of previous systems to deliver value. » more

Apps for Engineers: Sound meter, friction calculator, mechanical basics

CFE Media’s Apps for Engineers is an interactive directory of more than 170 engineering-related applications for Android and iOS operation systems, created by various companies. This month, gain access to a sound meter, a… » more

Condition-based maintenance offers a system check-up

Condition-based maintenance (CBM), when used with a computerized maintenance management system (CMMS), can help to implement a preventative maintenance plan. » more

October 2013

Safety and risk minimization in the operator control of plant machinery

Machine and operator safety must be considered at all stages of its service life and never become an afterthought » more

Technology an essential element of safety and asset management

Technology should be considered a key component of asset management and safety rather than just another tool » more

Study finds safety is a path to productivity

Results of a recent study showed that companies reporting the lowest injury rates also had the best productivity » more

The new Hazard Communication Standard: What you need to know to be compliant

Changes to OSHA’s Hazard Communication Standard (HCS) covers more than 43 million workers who produce or handle hazardous chemicals in more than five million workplaces across the country » more

Consider your technology, your workers to achieve effective crisis communications

Technology advances help make crisis management easier, but facility managers and planners need to remain vigilant and to keep their workers in the know about potential developments » more

U.S. safety codes: How we got here

An overview of the safety standards and organizations that have been formed since 1970 » more

Meeting regulations through networked safety

You shouldn’t sacrifice productivity—and with a good system, you don’t have to » more

A plant sets aside one day to focus on safety

Sapa Extrusions halted operations for a day to emphasize safety and best practices with its 6,500 workers » more

September 2013

Examine all factors when choosing between a reciprocating piston or rotary compressor

Making the correct choice between a reciprocating piston and a rotary compressor can be greatly beneficial for operations » more

Five ways to reduce energy consumption in your plant

Electrical power management systems deliver intelligence required » more

The uncompromising result of an unsafe workplace

Safety must be paramount and a major and permanent priority in the workplace and in life » more

July/August 2013

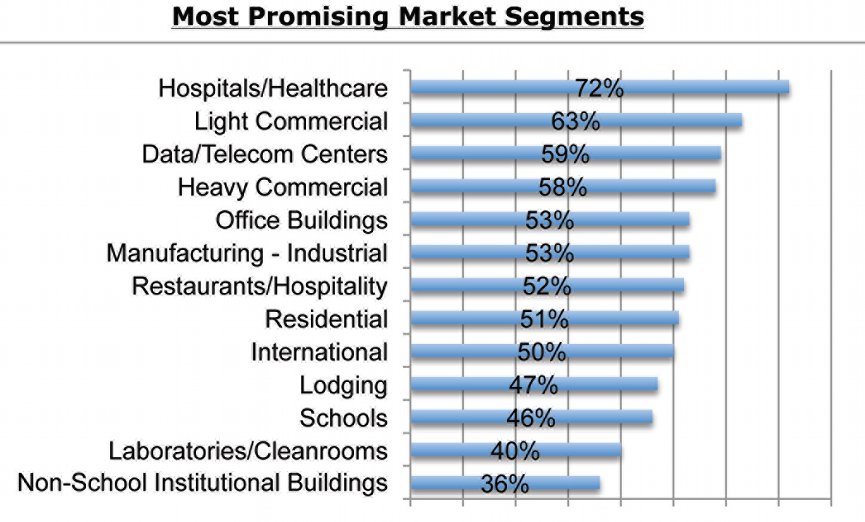

Despite hot issues, plant managers keep their cool

Companies all over the world are thriving and growing amidst the challenging economy, but certainty about the future remains murky » more

Of PLCs, control panels, and VFDs

PLCs have come a long way since the late 1960s and their applications in engineering are both innovative and seemingly endless. » more

Panel building: Optimizing control panel design, construction

Modern control panel wiring methods can reduce the costs of manufacturing and ownership. » more

June 2013

Bearing isolator

The Bearing Isolator has received IP66 rating for applications in severe duty and/or wash down environments at risk of contamination » more

Develop and execute a sound lubrication strategy

Ahmet Guven from Shell discusses lubrication strategies and methods for companies looking to improve efficiency and maintenance » more

Investing in economic efficiency

State-of-the-art specialty lubricants contribute to economic, success, or how a small investment makes the difference » more

May 2013

‘Trust, but verify’: A motto we can live with

Safety is becoming more and more important as counterfeit goods continue permeating the market » more

Pressurizing with dust collectors: Making the right decision

Indoor air quality: Choosing positive or negative pressure is a multi-faceted decision » more

April 2013

Investment in excellence

One plant’s improved productivity and quality was repaid when the company expanded the facility » more

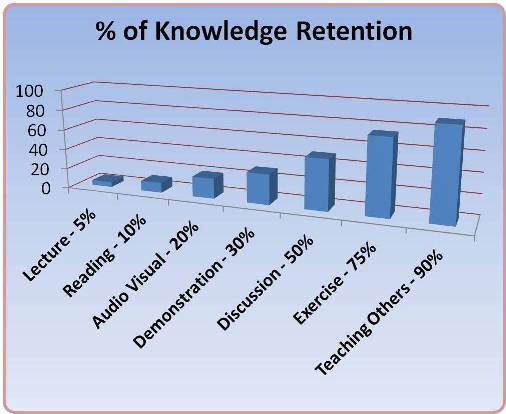

New tactics needed to develop a new workforce

Companies that invest in the right learning and development programs will better position themselves to accelerate skills development, improve organizational capability, and sustain business success » more

E-Stop buttons designed to enhance machine safety

While a risk assessment is a starting point to determine effective safety devices and methodologies, a key risk reduction component is the Emergency Stop » more

Pump efficiency drives cost savings

Many plants continue to consume far more power than is necessary to run their pump systems, simply because there is a lack of awareness of the losses. Recent educational efforts are starting to bring those issues to the forefront. » more

March 2013

NEP program guidelines should apply to any plant

An overview of the 14 elements that makes up the National Emphasis Program » more

Making sense of process safety

More than just a safety program, the National Emphasis Program focuses on change » more

Training, mentoring needed to address skilled worker shortage

Placed workforce development on top of their list of plant floor issues in the 2012 Plant Engineering salary survey, which is an issue that will continue to be a problem if it is not addressed » more

ARC President: Pick up the pace of technology adoption

Rapid growth of devices, technology use requires faster implementation on plant floor » more

January/February 2013

‘Are we there yet?’ isn’t the question to get you there

The jobs picture and the housing market are brightening, which both bode well for the manufacturing sector in particular and the economy as a whole. » more

2012 Salary Survey: It’s time to turn insight into action

View the results of Plant Engineering’s 2012 Salary Survey and insights from industry experts.

Additive technology carves a ‘path toward production’

Additive manufacturing has become a significant part of AMT’s long-term strategy. » more

Additive manufacturing is shaping the future

3D printing technology will change the way we make things » more

Click below to read content from other years

- 2016 Plant Engineering magazine archive

- 2015 Plant Engineering magazine archive

- 2014 Plant Engineering magazine archive

- 2012 Plant Engineering magazine archive

- 2011 Plant Engineering magazine archive

- 2010 Plant Engineering magazine archive