Asset management insights

- Artificial intelligence (AI)-powered tools can enhance asset management, saving time and unnecessary effort.

- Data is critical for effective asset management, and humans are critical for providing quality data used in asset management tools.

- Integrating tools like historians, enterprise asset management and computerized maintenance management systems is critical for success.

What’s the current trend in asset management for industrial and manufacturing facilities?

Christine Nishimoto: Facilities are moving away from reactive asset management and toward predictive asset management. In practice, this entails combining artificial intelligence (AI)-powered tools with an asset life cycle management (ALM) approach. It’s a trend with major benefits. Smarter ALM translates into time-saving automation, lower maintenance costs, increased sustainability and more.

Heath Stephens: The current trend has been to better optimize our limited maintenance resources and budgets. This means doing maintenance only when needed and ensuring maintenance is effective when performed. Over-maintaining assets means production lines are down unnecessarily; labor and expenses are wasted on nonproductive tasks and other assets go neglected. It also introduces the possibility of breaking a previously healthy asset in the process of servicing it. AI/machine learning (ML) solutions provide another tool to improve reliability and reduce maintenance costs.

What future trends should engineers, plant managers and designers expect for asset management in the next year or two?

Stacey Jones: Embracing industrial digital transformation is critical. This includes integrating AI/ML and internet of things (IoT)technologies to enhance predictive and preventive maintenance. Real-time data analytics will play a significant role in optimizing asset performance and reducing downtime.

There’s also a growing emphasis on sustainability and environmental, social and governance (ESG) strategies. Companies are increasingly aligning their asset-management practices with ESG goals to improve efficiency and reduce environmental impact

Doug Cooper: Over the next one to two years, engineers, plant managers and designers should expect the integration of asset management systems with operational systems to increase efficiency. This will be accomplished using AI/ML technologies that will provide greater insight into the health of plant equipment so reliability, maintenance and operations teams can enhance decision making. This increased interaction will improve equipment reliability and availability while meeting production needs that will maximize revenue and decrease costs.

Stephens: AI/ML tools for advanced predictive reliability and asset management are already here and have been for some time, but their cost and complexity barriers continue to fall. Over the next couple of years, I expect more integration of AI on the user interface/configuration side of the applications to make them even easier to deploy and maintain.

Nishimoto: Agentic AI has huge potential for asset life cycle management. I foresee AI agents that can continuously monitor sensor data from physical assets, detect anomalies and orchestrate the entire maintenance workflow. For example, these agents could predict failures before they occur, automatically schedule maintenance during optimal time windows, coordinate with inventory systems to ensure parts availability, dispatch technicians with the right skills and generate detailed repair instructions. The agent would learn from each maintenance cycle to improve future predictions and optimize the asset’s total cost of maintenance. IBM is planning to launch agentic AI for asset management later this year and we expect this technology to become an integral part of asset life cycle management.

How has the integration of artificial intelligence (AI) and machine learning (ML) impacted traditional asset management strategies?

Drew Mackley: AI can mean a lot of different things to a lot of different people. At Emerson, we have many different AI-driven solutions in our portfolio covering a wide array of use cases. For example, AI is built into wireless monitoring solutions to help identify and assess bearing and lubrication health — two common asset fault conditions. Some technologies even have first principles rules built in to guide the AI for a deeper dive into asset and process health. In both cases, the AI can help not only identify the problems but also provide severity, so personnel know how quickly they need to act.

This is where AI shines. There’s a lot of data and it can point to a lot of problems in rotating equipment, but they don’t all have the same severity or the same capacity to impact operations. Balance, misalignment, looseness and more are all common, but in many cases, an asset can run for years with those conditions. The most challenging solutions require some intelligence to sort out. People can do that, but it takes time to go through all that data and often, those expert personnel need to be doing other things. AI can help lighten that burden, doing much of the data analysis to free personnel up to fix and prevent the problems.

Jones: AI and ML automate many routine tasks, such as data entry and analysis, freeing up human resources to focus on higher-value activities.

AI-powered systems offer real-time monitoring of asset performance, enabling immediate responses to potential issues and optimizing asset utilization

AI and ML algorithms analyze vast amounts of data to predict when assets are likely to fail, allowing for timely maintenance and reducing unexpected downtime.

These technologies provide data-driven insights, helping asset managers make more informed decisions. AI can identify patterns and trends that might be missed by human analysis.

Cooper: The integration of AI/ML has increased and enhanced the insights available to engineers on equipment health. AI/ML allows customers to utilize increased data to move toward a more predictive maintenance culture and get out of a reactive mode of performing maintenance when equipment breaks down. It also provides prescriptive guidance to maintenance personnel on how to remediate the predicted failures on their equipment. This predictive and prescriptive guidance allows maintenance personnel to plan their work in a much more cost-effective manner, saving maintenance dollars and reducing downtime from unexpected equipment failures.

Stephens: Traditional asset management strategies are based on either scheduled maintenance routines or triggered by one or two key indicators. It is often unclear how effective the maintenance activities were. AI/ML analyzes multiple equipment health and process signals to develop a much more sophisticated profile of a properly operating asset. These multivariate asset profiles provide much earlier predictions of asset failures and better verification that maintenance activities were effective. This allows assets owners to better schedule nonroutine maintenance activities and better target which assets to perform routine maintenance.

Nishimoto: AI – from the more traditional machine learning to emerging generative AI capabilities – has been a boon for asset management strategies. AI tools and technologies can at once operate in detail and at scale, providing oversight that no human alone can match.

Describe the successes from using programs and systems that incorporate asset management. This may include IoT-based systems, industry 4.0, etc.

Stephens: It’s easy to forget sometimes that the latest technological advances depend on a foundation of other, sometimes older technologies. New AI/ML tools for asset management depend on a well-instrumented system. This may be from traditional wired instrumentation or from newer industrial (IIoT) sensors. Cloud services also bring the power of off-premises computing and external data analysis to better diagnose and predict asset issues.

What types of computer applications are in use to support your asset management functions?

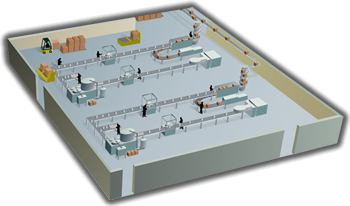

Jones: Applications such as enterprise asset management (EAM) and computerized maintenance management systems (CMMS),historians and distributed control systems all play a crucial role in supporting asset management. When these systems are properly integrated and leverage advanced technologies like AI, ML and generative AI’s large language model, the combined workflow can provide real-time alerts, identify likely root causes and recommend actions. When you couple this with planning and scheduling tools, you can create a comprehensive response to upset events. In the next few years, I think these types of systems will be used to augment human decision making but will become more automated overtime.

Tell us about a recent asset management project you’ve worked on that’s innovative, large-scale or otherwise noteworthy. Please tell us about the location, plans your team engineered, key players, interesting challenges or solutions and other significant details.

Nishimoto: IBM recently acquired Prescinto, an India-based company specializing in renewable asset performance management. We’re currently adding its capability into IBM Maximo Application Suite, our asset management solution.

Renewable energy asset management is a tricky business: solar farms, wind turbines and battery storage facilities are big, complicated and far-flung assets. And by their very nature they are exposed to the elements. Without the right asset management approach, these renewable energy assets can quickly turn into liabilities. We are excited to continue innovating in this space, making renewable energy assets even more productive.

Mackley: A multinational food producer in North America sought to better understand which assets were or would soon be experiencing mechanical or electrical faults, both of which indicate potential runtime disruptions. The company needed an enterprise-level solution that would simplify data management, automate workflows and facilitate timely decision making. With tens of thousands of intelligent field devices and valves scattered across facilities worldwide, this meant knowing not only what to monitor and how often but also how to discern critical from noncritical issues when problems were detected. Decision makers needed to accelerate turnarounds and repairs in the safest and fastest way to minimize lost production, requiring better understanding of root causes and the ability to diagnose them.

For many years the company used Emerson’s intelligent field device management software, Association Management Specialist (AMS) Device Manager, as a foundational digital transformation solution. Using the solution, the company could manage tens of thousands of automation assets –– such as analytical and process instruments (pressure, flow, level, industrial wireless devices and temperature) and digital valve controllers –– all of which communicate using Highway Addressable Remote Transducer industrial field protocol. The versatility of AMS Device Manager allowed the company to communicate with both Emerson automation assets and those from other manufacturers.

Over years of steady success with its software-based intelligent field device management work practices using AMS Device Manager, the company had scaled its AMS Device Manager system count to more than 30 individual systems globally. Typically, one unique AMS Device Manager system may be assigned to manage a specific plant or production zone and each is able to be managed semi-independently by local maintenance in each physical location.

In 2020, the company successfully debuted its AMS Optics platform and in recognizing its value, has subsequently expanded the system by adding data connections to ingress data from additional AMS Device Manager systems corresponding to more plant sites or zones. In 2024, the system grew to include 12 AMS Device Manager systems monitoring around 21,000 devices globally — and now includes a portion of the company’s European operations. The company added eight additional system connections from across North America, South America and Europe bringing them to 20 connected systems and around 24,000 devices.

Once connected, the further contextualized alert data and dashboards proved to add quick value to system users. Now, alerts on health and other process alert data derived in the field can be viewed, accessed and purposed across the business network, helping to break down organizational siloes. Previously, the information was only available locally, requiring a sign-in to AMS Device Manager at the plant level and then further manual work to deliver the data in the format needed.

The company is also expanding to include AMS Machine Works systems in AMS Optics, which enables monitoring health of rotating equipment like pumps, motors or gearboxes. Just as was done with its network of valves and instrumentation, the company teams will now be notified of emerging mechanical issues like rolling element bearing defects, lubrication, misalignment, imbalance and others. This increased level of awareness and timely notification will empower users to perform exception-based analysis versus inspecting every piece of data collected, driving increased productivity and efficiency. It also allows users to extend the powerful capabilities of AMS Optics’s workflow and collaboration benefits to its reliability teams, who perform vibration analysis, as well as the maintenance teams that are responsible for control valves and instrumentation.

When considering your most effective asset management strategies, what are the advantages?

Cooper: The most effective asset management strategies provide a greater understanding of equipment health that will allow decisions to be made on when the equipment needs to have intrusive maintenance performed to prolong the life of the equipment. Understanding equipment health will allow standard preventive maintenance strategies and routines to be optimized. This way, only necessary maintenance is performed and extraneous maintenance activities can be eliminated. This optimization will free up maintenance resources to concentrate on planning for the necessary maintenance activities at the right time to optimize production requirements. This will ultimately result in huge cost savings on maintenance and increased revenue from decreased downtime.

Describe how you use enterprise resource planning (ERP) and other systems to provide better data and information flow throughout the company.

Cooper: ERP can be combined with asset management software to offer a comprehensive view for managing equipment. By combining the information in ERP systems, operators and maintenance personnel can effectively plan any work that needs to be done on the equipment by understanding spare part levels and upcoming maintenance on equipment. ERP data can also be utilized to identify the bad actors in the equipment by helping to calculate mean time between failure or overall equipment effectiveness. This helps maintenance and reliability personnel focus on the equipment that is causing the most issues at the facility.

What are some of the key challenges for improving asset management at your facility?

Nishimoto: I work with manufacturers around the world to improve their asset management strategies. While no two manufacturers are exactly alike, there are a handful of common challenges manufacturers face in this department. Many manufacturers have a patchwork of asset management systems and tools rather than a unified solution. Many still have a mindset focused on reactive maintenance rather than predictive or financially optimized maintenance. And many believe harnessing AI on their factory floor requires a small army of computer scientists. Today’s AI tools are accessible and require little or no coding experience to train and operate.

Jones: One of the biggest challenges is effectively tracking and managing assets. This includes keeping accurate records of asset location, condition and maintenance history.

Scheduling and planning maintenance tasks can be complex. Identifying the right time and resources for maintenance activities is crucial to prevent equipment failure and ensure optimal performance.

Managing and securing vast amounts of data generated by asset management systems is a significant challenge. Ensuring data integrity and protection against cyberattacks is essential.

Balancing the costs associated with asset management, including maintenance, upgrades and replacements while optimizing asset utilization is a continuous challenge.

What tips would you offer to someone newly tasked with asset management duties?

Jones: Use data analytics to monitor asset performance and identify areas for improvement. Data-driven insights can lead to more efficient and effective asset management.

Use EAM systems and other relevant software to streamline processes. These tools can help with tracking, scheduling and data analysis.

Stay updated with the latest trends and technologies in asset management. Attend workshops, webinars and training sessions to enhance your skills.

Nishimoto: One word of advice: data. Every workstation, assembly robot, conveyor belt and motor produce real-time data. When harnessed correctly, asset managers can unlock enormous benefits. Setting AI models to work on this data can generate new insights, like predictive maintenance recommendations and heightened productivity, like automated inspections.

Cooper: There are several recommendations for someone newly tasked with asset management duties. First, examine existing data and determine what pieces of equipment are causing the most issues in terms of downtime and repair costs. This will allow asset management professional to concentrate on those areas that will show the most benefit quickly. Secondly, ensure there is sufficient data being fed into systems that allow decisions to be made about how much and when maintenance should be performed. Third is to establish lines of communication between various disciplines such as reliability, maintenance, subject matter expertise and operations.