Numbers clarify protection levels for liquids and solids

What Is IP69K?

With an ever-increasing emphasis on safety operations in facilities, many of the products and equipment used in industrial plants must undergo and pass rigorous testing procedures and uphold a long list of standards. For a wide range of markets, devices strive to carry an IP69K rating, the highest rank on the Ingress Protection (IP) rating scale. This particular IP rating classifies a high degree of protection against the intrusion of liquids and solids into industrial devices and added safety and sanitization within plant operations.

The IP rating system is an internationally recognized scale, published by the International Electrotechnical Commission (IEC), to provide decision-makers with detailed information about how their products can hold up against environmental factors that may occur in industrial plants. By defining a specific rank, rather than using vague terms such as “waterproof,” the IP system ensures specific degrees and expectations when products are faced with solid objects of certain sizes and liquids of varying temperatures and pressures.

IP ratings contain two numbers; the first refers to the amount of protection against solid particles and the second refers to protection against liquids. The first number, which can be assigned as 0-6, ranges from no protection against any object to dust-tight and complete protection against contact. Devices with lower numbers are effective against large surfaces and parts of the body, while those with higher numbers can protect against tools, wires, and dust. The 6 rating indicates a dust-tight enclosure.

The second number of the IP rating, which categorizes a product’s protection against harmful entrance of water, ranges from 0-9k. Products with lower numbers offer protection against dripping water, while those with higher numbers are effective against spraying water, water jets, and immersion. The 9k rating signifies that a device is protected against close-range, high-pressure, and high-temperature spray downs.

What Are The Advantages Of IP69K?

Products with higher IP ratings are better suited to stand up against harsh environments and factors, and the IP69K rating ensures the highest degree of protection against objects/dust and liquid intruding into the enclosures of devices and equipment. This particular rating was originally specified for road vehicles, such as cement mixers and dump trucks, that needed to withstand regular intense cleaning and could hold up against steam and high-pressure water. It has also been widely adopted by plants in the food and beverage industry, where equipment must be thoroughly cleaned and sanitized without allowing chemicals or objects to interact with food items.

Products that carry the IP69K rating are ideal for facilities where hygiene and cleanliness are critical, as they are proven to be durable and resistant against water, chemicals, high pressure, and high temperatures associated with demanding cleaning and safety measures.

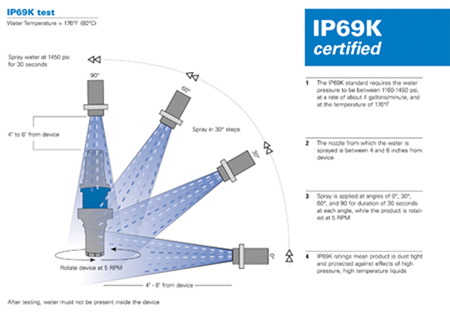

In order to bear an IP69K rating, products must endure rigorous procedures to test protection against penetration of high-pressure, high-temperature water and dust. One challenge, the water intrusion test, is conducted by placing the product on a turntable that rotates every 12 seconds (5 rpm) and spraying 176 F water from 4-6 in. at a flow rate of 4 gal per minute. The water pressure is between 1160-1450 psi and is sprayed at angles of 0, 30, 60, and 90 deg for 30 seconds each.

Andrew Bernard is the marketing manager for the industrial product lines at Eaton’s Cooper Wiring Devices business located in Peachtree City, Georgia.