With IMTS 2012 just a few weeks away, here's a preview into some of the products that will be shown at this year's show in Chicago.

Here are some of the products and innovations some of the top manufacturers will be showcasing at IMTS 2012 at the McCormick Place in Chicago on Sept. 10-15. Also included is the booth number the companies will be demonstrating their products

Mini Mezzanine

The Mini Mezzanine maximizes usable storage footprint and has a Storage Wall System with an aluminum slat tambour door, double bank Technician Series toolboxes, and Align adjustable-height workstations with the Nexus system of above-work surface accessories and modular components. The Mini Mezzanine takes advantage of all available height in a storage area and is a cost-effective alternative to building an additional floor or adding square footage. Comprised of stacked high-density storage cabinets, it is ideal for storing everything from maintenance and repair parts and supplies to perishable tooling and CNC tooling.

Lista (IMTS Booth W-2251)

30i-B/31i-B5 CNC with High-speed Smooth TCP

The 30i-B/31i-B5 CNCs use High-Speed Smooth TCP with new fairing technology to drastically reduce cycle times while improving part accuracy and quality. In addition they offer a high-speed and large capacity, multi-path PMC that offers large-scale sequence control with a maximum of five concurrent independent ladders. Execution of common instructions is over 2.5 times faster than previous generation, with additional capability of high-speed module executing every 1 msec. Improved operability is also achieved with the Series 30i-B CNCs using the new hand held operator’s unit iPendant for CNC.

FANUC FA America (IMTS Booth S-8919)

End mills

Cyclo Cut Max-Flute end mills innovate titanium roughing with a 16-flute design capable of high removal rates at low torque. The high-density end mills run at 2,037 rpm and 5.8 m/min to achieve removal rates of up to 131 cm3/min with only 33.8 nm of torque and 6.7 kW. Max-Flute end mills maintain a constant angle of engagement, making the radial cuts more consistent throughout the cutter path, increasing material removal rates and decreasing cycle times.

MAG (IMTS Booth S-8519)

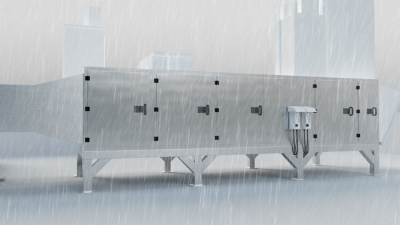

Multi-tumbling batch machines

The RMT multi-tumbling batch blast machines produce blast coverage results and have no “pinch points” to damage even sensitive parts. The RMT also features a simple design with few moving parts ensuring high up times and low maintenance costs. Easy automation with custom-made loading and unloading equipment make integration into existing systems a breeze. The RMT machines suit every capacity requirement from 3-34 cu. ft. batch sizes and include a wide choice of blast turbines from 15-75 hp.

Rosler (IMTS Booth N-7432)

Laser heat-treating systems

The series of Laser Heat-Treating Systems utilize precise laser technology to treat localized areas of metal components without altering the properties. The systems are ideal for use in automotive, heavy equipment, aerospace and general industrial manufacturing. Its active process control, which provides real-time thermal feed back, guarantees the proper temperature to eliminate damged parts and accomodiates variations that are common in materials from lot to lot. The Heat-Treating Systems accept Nd:YAG, CO2, UV and fiber lasers.

Preco, Inc. (IMTS Booth N-6530)

Carbide drill

The Coromant CoroDrill 860 solid carbide drill provides fast, economical, problem-free drilling, optimized for steel and most recently for high productivity in all types of aluminum. In addition, visitors can preview a multi-application, high-performance drill that can be used across a wide range of materials. For the exchangeable-tip drills, the CoroDrill 870 will be extended with an optimized grade and geometry for cast iron materials.

Sandvik (IMTS Booth W-1500)

Vertical machining center

The VM3224 is a vertical machining center with a 38 x 24" table. The VM3224 has travels of 32 x 24 x 26". The enclosure is designed with removable side doors for accessibility through full saddle travel to accommodate long parts. VM3224 is equipped standard with 8200 CNC Control, linear roller ways, dual arm 24-pocket tool changer, 6-spigot flood coolant, 180 gal coolant capacity, and chip auger.

Milltronics (IMTS Booth S-8329)

Milling control

The TNC 640 Control is a milling control offered with optional turning enabling it to perform multi-operation machining. Just as with all other TNC controls, the user only needs to enter all the programming steps for turning operation in plain language, just as he does for milling. It also has an optimized user interface, which gives the user greater transparency during programming, presents functions better and displays status information more clearly. The TNC 640 has a stainless steel control design and a specially prepared keyboard surface and screen frame to eliminate fingerprints.

Heidenhain (IMTS Booth E-5224)

Multi-tasking machine

INTEGREX i-630V Multi-Tasking Machine is designed for aerospace and other large component manufacturing sectors. This Multi-Tasking Machine performs turning and milling and provides B-axis and C-axis capabilities. Its turning and milling spindles allow for powerful and accurate full simultaneous five-axis machining.

Mazak (IMTS Booth S-8300)

Abrasive waterjet technology

OMAX 80X-1 DualBRIDGE JetMachining Center and MAXIEM 1530 and 0707 JetCutting Centers are abrasive waterjet technologies that provide conventional machining operations for a wide variety of industries and shop sizes. OMAX and MAXIEM machines cut a wide range of materials advanced composites and exotic alloys to traditional metals, rubber and glass.

OMAX Corporation (IMTS Booth N-6228)

Toolholder system

PRECI-FLEX toolholder system is a fast, accurate and cost-effective solution for lathe tooling changeovers. It is the first system of its kind to have a single base holder and multiple tooling adapters that utilize the ER collet pocket. Available in a range of sizes, PRECI-FLEX provides unsurpassed performance consistency, with every toolholder offering repeatability within five microns.

Exsys Tool (IMTS Booth W-1664)

Machine precision tool

The LR7000 notifies the operator of a gap between the work piece of any material and the stop. It not only reduces miss-loads, but it also signals the operator of a shift during machining. This fully sealed unit remains illuminated under high flow coolants, communicating to the operator that the part has not moved away from the stop. Durable Vise Mount and Table Mount applications allow for quick and easy location around your shop.

R&R Tool, Inc. (IMTS Booth E-5427)

Wire machines

MV wire machines feature design and engineering improvements to exceed all other wire EDM machines on the market, including: non-contact cylindrical drive technology, an improved power supply, auto-threading, deeper submerged-wire threading capabilities, and more. The cylindrical drive technology delivers no wear, no cogging (inherent in flat plate systems), and no backlash – all for better energy-efficiency, accuracy, and speed.

Mitsubishi (IMTS Booth N-6825)

Interface controller

The PSSR-2 interface controller has a safety performance of CAT 3 SIL2 PLd, EN 13849. It has built in integrity monitoring for presence sensing safety mats, edges, and switches with a resistor. It has a manual and auto reset. There are 3 output contacts; force-guided relays and 2 normally open (safety) 1 x normally closed (monitor) contacts. It is 22.5 mm DIN rail mountable.

Tapeswitch Corporation (IMTS Booth E-5814)