Arc welding is safe when sufficient measures are taken to protect the welder from potential hazards. When these measures are overlooked or ignored, welders can encounter such dangers as: electric shock, overexposure to radiation, fumes and gases, fire, or explosion, any of which can result in fatal injuries.

Key concepts

Wearing protective clothing safeguards welders.

Check welding equipment often to ensure its optimum performance.

Remove hazardous materials from the welding area.

Sections: Personal protection Shock hazards Radiation Fumes Ventilation Fire hazards Explosion hazards

Sidebars: Inspection and maintenance of equipment and work Natural ventilation is sufficient when welding and cutting mild steels provided these requirements are met:

Arc welding is safe when sufficient measures are taken to protect the welder from potential hazards. When these measures are overlooked or ignored, welders can encounter such dangers as: electric shock, overexposure to radiation, fumes and gases, fire, or explosion, any of which can result in fatal injuries.

Personal protection

Protective clothing must allow freedom of movement while providing adequate coverage against burns from sparks, weld spatter, and arc radiation. Many types of clothing offer protection from ultraviolet (UV) radiation exposure, which appears as a skin burn, much like sunburn.

Because of its durability and resistance to fire, wool clothing is suggested instead of synthetics, which melt when exposed to extreme heat, or cotton, unless it is specially treated for fire protection.

Keep clothes free of grease and oil; these substances may ignite and burn uncontrollably in the presence of oxygen.

Avoid rolling up sleeves and pant-cuffs because sparks or hot metal could get stuck in the folds. Wear trousers that overlap work boots, not tucked in, to keep particles from falling into the boots. Leather high-top boots with steel toes are recommended, especially when doing heavy work.

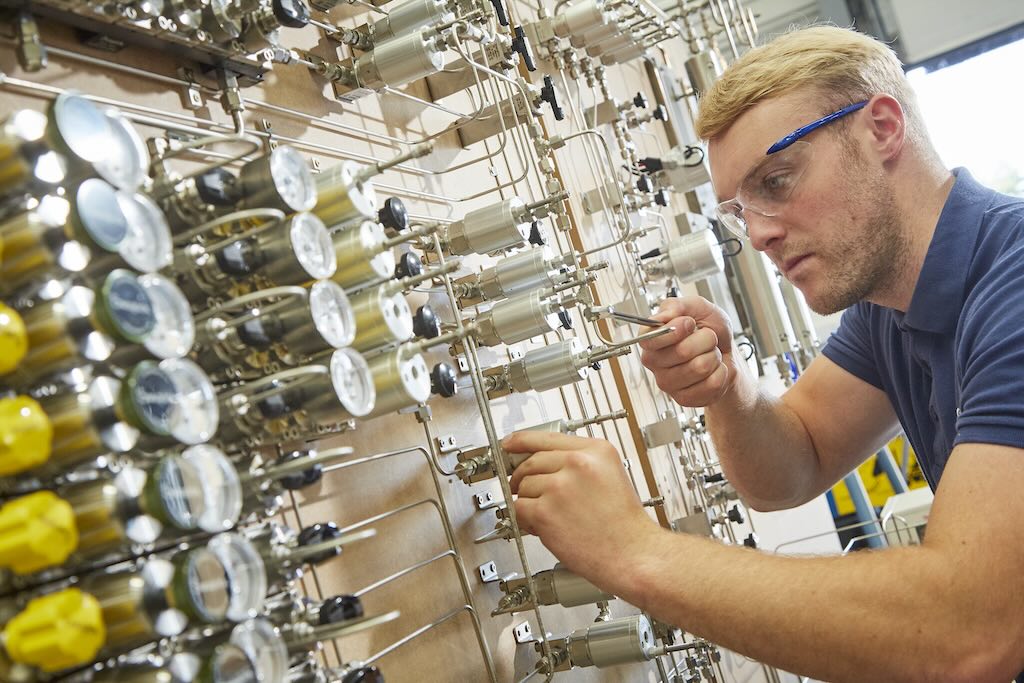

Other protective wear for heavy work or especially hazardous situations includes flame-resistant suits, aprons, leggings, leather sleeves/shoulder capes, and caps worn under a helmet (Fig. 1).

Fig. 1. Protective wear shields the welder from heat, sparks and UV radiation.

Heavy, flame-resistant gloves, such as leather, should always be worn to protect hands from burns, cuts, and scratches. As long as they are dry and in good condition, they offer some insulation against electric shock.

Shock hazards

A shock can be received from primary (input) voltage by touching a lead inside the welder with the power to the welder “on” while having your body or hand on the welder case or other grounded metal. Remember, turning the welder power switch “off” does not turn the power off inside the welder. The input power cord must be unplugged or the power disconnect switch turned off.

A secondary voltage shock can occur when touching a part of the electrode circuit, such as a bare spot on the electrode cable, at the same time a part of the body is touching another side of the welding circuit, the work, or welding ground.

The conditions that increase the likelihood of a severe shock are wet conditions and welding in or on a metal workpiece.

Use plywood, rubber mats, or other dry insulation to stand or lie on. Keep gloves dry, even if this means keeping an extra pair. Don’t rest body, arms, or legs on the workpiece, especially if clothing is wet or bare skin is exposed.

Under such very poor welding conditions, follow these rules or use a semiautomatic, constant voltage welder with cold electrode or a stick welder equipped with a device to reduce voltage at the electrode when no welding is being performed.

Plastic or fiber insulation on the electrode holder prevents contact with “electrically hot” metal and parts inside. Always inspect the electrode holder before turning the welder on. Replace the holder if it is damaged. Don’t try to repair it unless replacement parts are at hand.

A damaged electrode cable should be replaced or, at minimum, repaired using electrical tape. If the cable has been repaired, check that the tape is secure before turning the welder on.

A stick electrode is always “electrically hot” when the welder is on; treat it with respect. If a shock is experienced, think of it as a warning. Check equipment, work habits, and work area to determine what is wrong before continuing to weld.

Radiation

It is essential that eyes be protected from radiation exposure. Even a brief exposure to UV radiation can cause eye burn known as “welder’s flash.” While this condition is not always apparent until several hours after exposure, it causes extreme discomfort and can result in swelling, fluid excretion, and temporary blindness. Normally, welder’s flash is temporary, but repeated or prolonged exposure can lead to permanent eye injury.

Besides not looking at an arc, the only other preventative measure is the use of proper eye-shading filters. The general rule is to choose a filter too dark to see the weld, then move to lighter shades without dropping below the minimum protective rating.

Helmet-type shields and handheld face shields offer the most complete shading against arc radiation. The shields protect the head, face, ears, and neck from heat, sparks, and flames. As a minimum, use safety glasses with side shields or goggles to protect eyes from flying particles (Fig. 2).

Fig. 2. Side shields on eyewear help protect eyes from flying particles.

While infrared radiation can usually be felt as heat, there is no real way to tell if you’re being exposed to UV radiation. Don’t take any chances and always wear eye protection.

Fumes

Fume plumes contain solid particles from consumables, base metals, and base-metal coatings. Depending on the length of exposure to these fumes, most acute effects are temporary, and include symptoms of burning eyes and skin, dizziness, nausea, and fever.

Zinc fumes can cause metal fume fever, a temporary illness that is similar to the flu. Chronic long-term exposure to welding fumes can lead to siderosis (iron deposits in the lungs) and may affect pulmonary function.

Cadmium is a toxic metal found on steel as a coating or in silver solders. Cadmium fumes can be fatal even under brief exposure, with symptoms much like those of metal fume fever. Twenty minutes of welding in the presence of cadmium can be enough to cause fatalities. Symptoms appear within an hour, and death may occur five days later.

The gases that result from an arc welding process also present a potential hazard. Most of the shielding gases (argon, helium, and carbon dioxide) are non-toxic, but as they are released they displace oxygen in the breathing air, causing dizziness, unconsciousness, and death if the brain is denied its needed oxygen long enough.

Heat and UV radiation can irritate lungs and cause eyes to tear. Some degreasing compounds such as trichlorethylene and perchlorethylene can decompose from heat and UV radiation to form phosgene, a highly toxic gas. Ozone and nitrogen oxides are formed when UV radiation meets air. These gases cause headaches, chest pains, irritation of the eyes, and itchiness in the nose and throat.

Keep your head out of the fume plume. Use mechanical ventilation or local exhaust at the arc to direct the fume plume away from the face (Fig. 3). If this is not sufficient, use fixed or moveable exhaust hoods to draw fumes from the general area.

Fig. 3. Ventilation should draw all welding fumes away from the work.

It may be necessary to wear an approved respiratory device if sufficient ventilation cannot be provided. As a rule of thumb, if the air is visibly clear and you are comfortable, then ventilation is probably adequate.

Read the material safety data sheet (MSDS) for the electrode to see what fumes can be reasonably expected from its use. The appropriate MSDS should be posted in the work place. Know what the base metal is and determine if there is any paint or coating that could cause toxic fumes and/or gases.

If you feel feel dizzy or nauseous, there is a possibility you were overexposed to fumes and gases or are suffering from oxygen deficiency. In either case, try to improve the ventilation in the area. If that doesn’t work, turn off the welder, get some fresh air immediately, and notify coworkers.

Ventilation

Adjustable hoods, fixed enclosures, or booths can provide local exhaust of welding fumes. Individual movable hoods are particularly suitable for bench welding, but they can be used for any welding or cutting job, provided the hood is always close to the area being welded.

When arc welding in a confined area, all the hazards associated with welding are amplified. There is great danger that enough flammable gases or vapors may be present to cause an explosion.

Welding fumes can accumulate rapidly, with high concentration, and can force out breathable air, suffocating the welder in the process.

For work in any kind of enclosed area, ensure adequate ventilation or use an air-supplied respirator. Have someone trained to handle emergencies positioned outside the enclosure and able to pull you out if danger arises. Provide a means for this person to disconnect power to the equipment. Do not attempt work of this nature without constant communication with the person outside the confined area.

Fire hazards

Because of the extreme temperatures associated with any arc welding process, always be aware of fire hazards. The welding arc can reach temperatures of 10,000 F, but this heat in itself is not generally a fire hazard.

The danger of fire results from the effects of this intense heat upon the work and in the form of sparks and molten metals. Because these can spray up to 35 ft from the work, recognize and distance yourself from combustible materials. It is also important to be sure the work is not in contact with any combustible, which it may ignite when heated.

Observe where sparks and metals are falling. If there are flammable materials, including fuel or hydraulic lines, in the work area, and they or the work can’t be moved, put a fire-resistant shield in place.

If welding above the ground or from a ladder, be sure there are no combustibles underneath. Don’t forget about coworkers, who wouldn’t appreciate being hit with slag or sparks from the work. Firewatch personnel may be required.

Particular care must be taken when welding or flame cutting in dusty locations. The dust may be extremely volatile in the heat of the arc or in the presence of a hot spark. Dust particles may readily oxidize and result in a flash fire or an explosion.

Before starting to weld, inspect the surface of the work. Look for flammable coatings or any unknown substances that would ignite when heated. There are extreme fire and explosion hazards inherent to welding on or around containers and piping that may have combustible materials.

Know where fire alarms and fire extinguishers are located. If there are none in the area, be sure there is access to fire hoses, sand buckets, fire-resistant blankets, and other fire fighting equipment.

If welding within 35 ft of flammable materials, have a firewatcher observe where sparks are flying and have an extinguisher or alarm handy. Both you and the firewatcher should wait for a half-hour after all welding is finished to find and put out any smoldering fires that may have resulted from welding.

When emergencies result from welding accidents, the first rule is don’t panic. Depending on the size of the fire, shut off the welder, sound the fire alarm to warn others and the fire department, and get to the fire exits as quickly as possible.

Explosion hazards

Because of the explosive nature of welding gas cylinders, pay particularly close attention to their storage and use. Examine the cylinder and check the label to ensure it is the correct shielding gas for the process. Check that regulators, hoses, and fittings are the right ones for that gas and pressure and are in good condition.

Cylinders must be stored in an upright position, with the valve caps in place, in an area away from combustibles and fuels, and safeguarded from damage, heat, and flames. When they are in use, keep them out of traffic routes and away from flying sparks, with all hoses run neatly to the welding area. Never allow the electrode or other “electrically hot” parts of the welder to touch a cylinder. Never move cylinders without the valve cap in place.

— Edited by Joseph L. Foszcz, Senior Editor, 630-320-7135, [email protected]

Inspection and maintenance of equipment and work

For the welder:

Are all connections tight, including the earth ground?

Are the electrode holder and welding cable in good condition?

Are the settings correct for the job?

For an engine-driven welding machine:

Is it running OK?

Are all hoses on tight?

Is the fuel cap on tight?

Is the engine leaking gasoline or oil?

Are the original enclosure and fan guarding in place?

For the work in general:

Are the cables the right size for the job?

Are they spread out and run neatly to prevent overheating?

Is the gas cylinder connected properly?

Is the cylinder secure?

Is the work stable and easy to reach?

Is the work lead connected securely?

Is there enough insulation between your body and the work piece?

Is there adequate ventilation in the area?

Natural ventilation is sufficient when welding and cutting mild steels provided these requirements are met:

The room or welding area contains at least 10,000 cu ft (about 22 ft x 22 ft x 22 ft) for each welder.

The ceiling height is not less than 16 ft.

Cross ventilation is not blocked by partitions, equipment, or other structural barriers.

Welding is not done in a confined space.

Spaces that do not meet these requirements should be equipped with mechanical ventilating equipment that exhausts at least 2000 cfm of air for each welder, except where local exhaust hoods, booths, or air-line respirators are used.