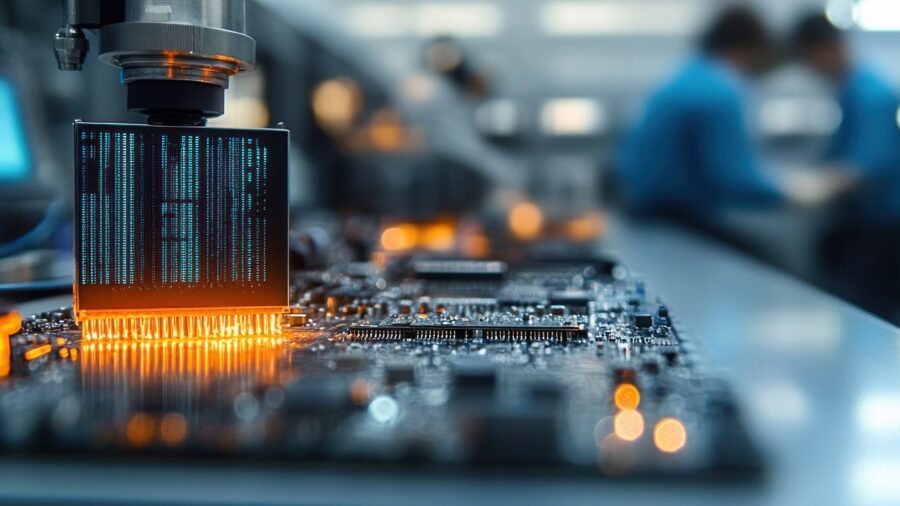

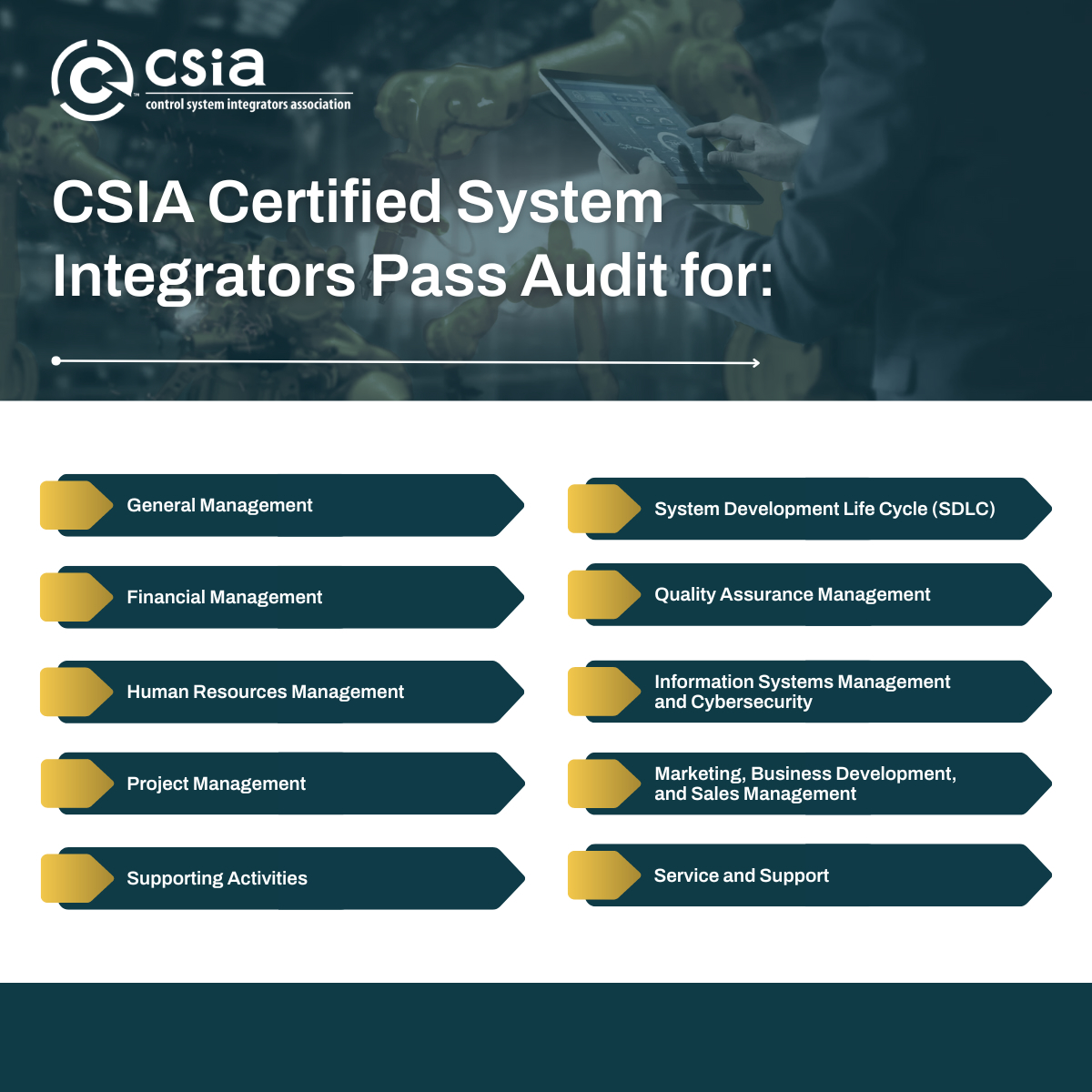

System Integration

System integration connects devices and systems, often with computers, software and networks, to optimize throughput or the process. System integrators for automation and controls design and integrate computerized control systems for industrial machines, manufacturers or facilities.