Motor selection starts with accurate calculations. From power and torque to duty class and efficiency, properly sizing and specifying a motor is essential to building a reliable, energy-efficient drive system.

Learning objectives

- Understand how to perform basic motor calculations — including power, torque and speed — to accurately size a motor for specific load and duty cycle requirements.

- Identify key motor selection criteria such as duty class, efficiency ratings (IE standards) and environmental conditions and understand their impact on performance, reliability and energy consumption.

- Evaluate the benefits of integrating motors with gear units and variable frequency drives (VFDs) to optimize system efficiency and reduce long-term operational costs.

Motor insights

- Selecting the right motor is critical for ensuring efficiency, reliability and cost savings in industrial applications, as it must match the specific load, duty class and environmental conditions of the system.

- This guide simplifies motor calculations, explains key concepts like duty classes and load types and highlights how integrating motors with gear units and variable frequency drives (VFDs) creates a reliable and efficient drive system.

Selecting the right motor is like choosing the right engine for a vehicle. A car engine in a semi-truck might get the job done briefly, but it won’t last long, just like an undersized motor in a demanding application. Similarly, an inefficient motor is like a car with a leaky fuel tank — it wastes energy and money every time it runs.

Choosing the wrong motor can lead to inefficiency, overheating or even premature failure. Here are key factors to consider:

- Power requirements (horsepower, or hp): Power reflects the motor’s ability to handle the load under both operational and peak conditions. Under-sizing risks motor failure, while oversizing leads to energy waste. Think of it this way: an overpowered motor running constantly is like leaving the lights on in every room of your house when you only need one lamp.

- Torque and speed: Torque (pounds per foot) is the motor’s twisting force (F) and speed (revolutions per minute) determines how fast it spins.

- Constant torque applications: Conveyors and mixers require steady force regardless of speed.

- Variable torque applications: Fans or pumps require less torque at lower speeds, making them ideal for energy-saving strategies.

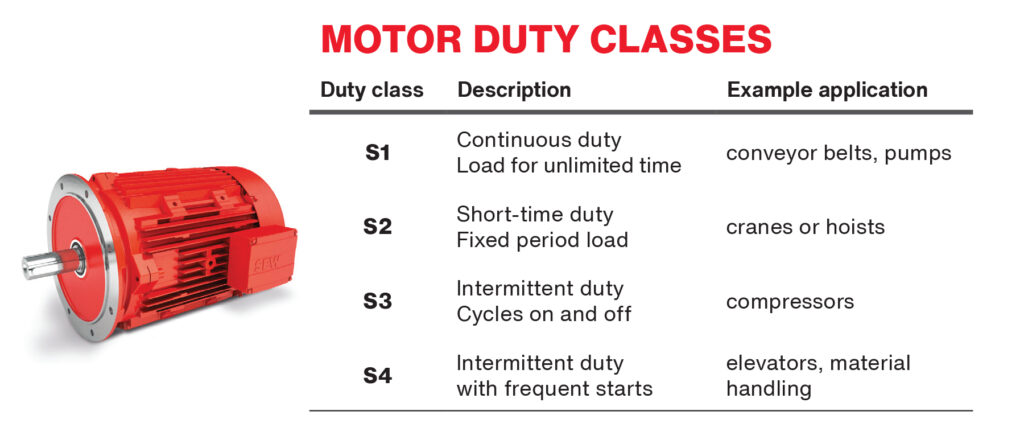

- Duty class: Duty classes describe how often and how long a motor operates under load. Choosing the wrong duty class can lead to overheating or unnecessarily high costs.

- S1 (continuous duty): Full load for unlimited time (e.g., conveyor belts or pumps).

- S2 (short-time duty): Full load for a fixed period, then cooling (e.g., cranes or hoists).

- S3 (intermittent duty): Cycles on and off to prevent overheating (e.g., compressors).

- S4 (intermittent duty with starting): Includes frequent starts, perfect for elevators or material handling systems.

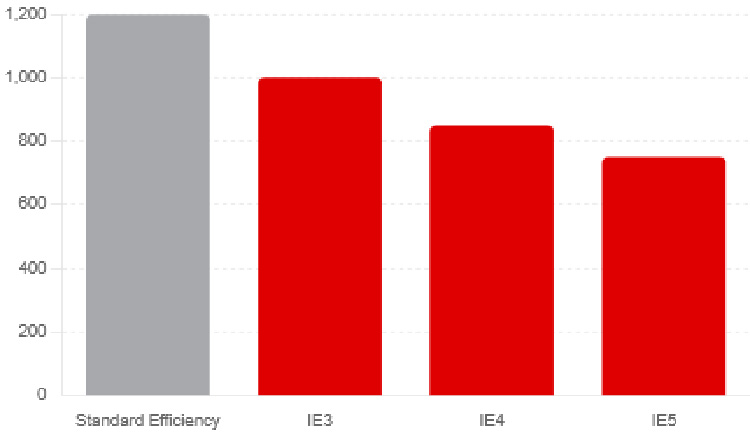

- Efficiency (international efficiency, or IE): Efficiency determines how well a motor converts electricity into work. Higher efficiency motors (IE3, IE4 or IE5) reduce energy waste over time.

- Environmental conditions: Motors exposed to dust, moisture or heat require appropriate enclosures and cooling systems to maintain performance and reliability.

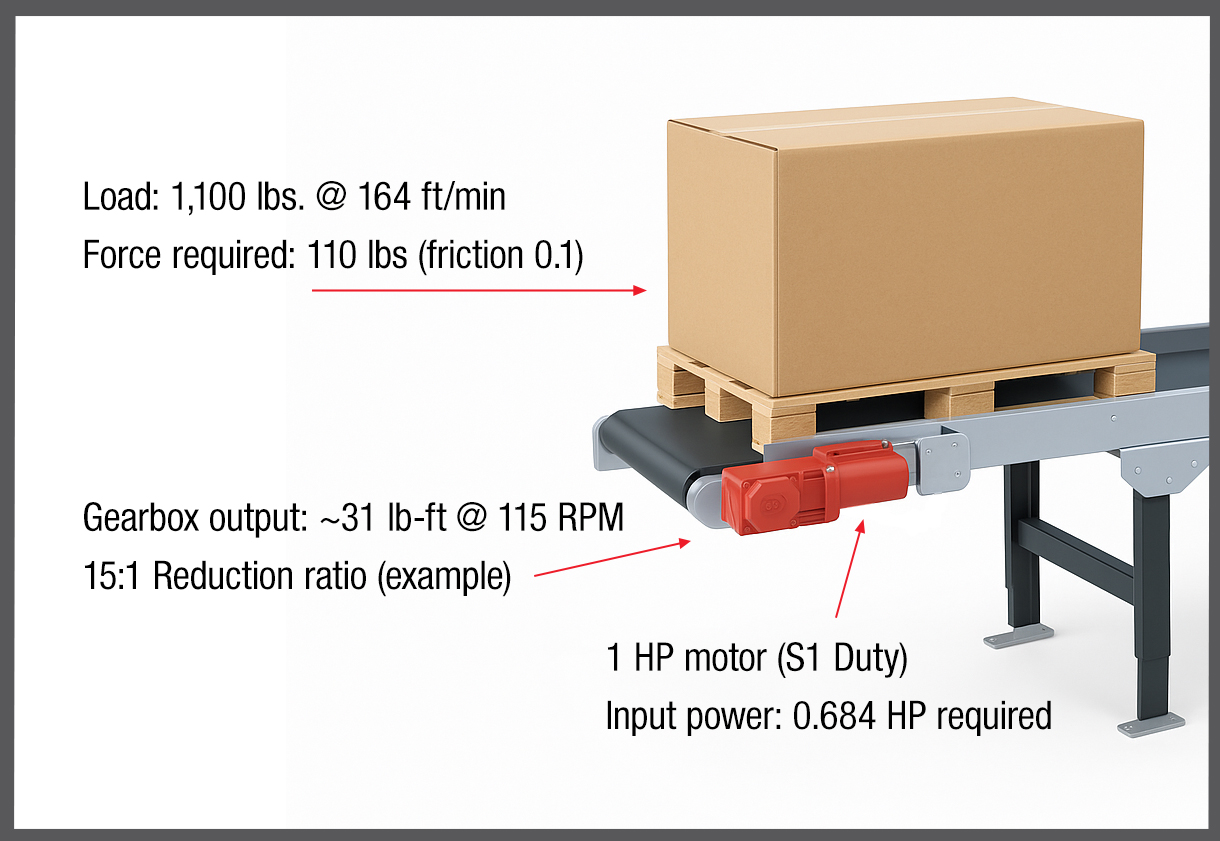

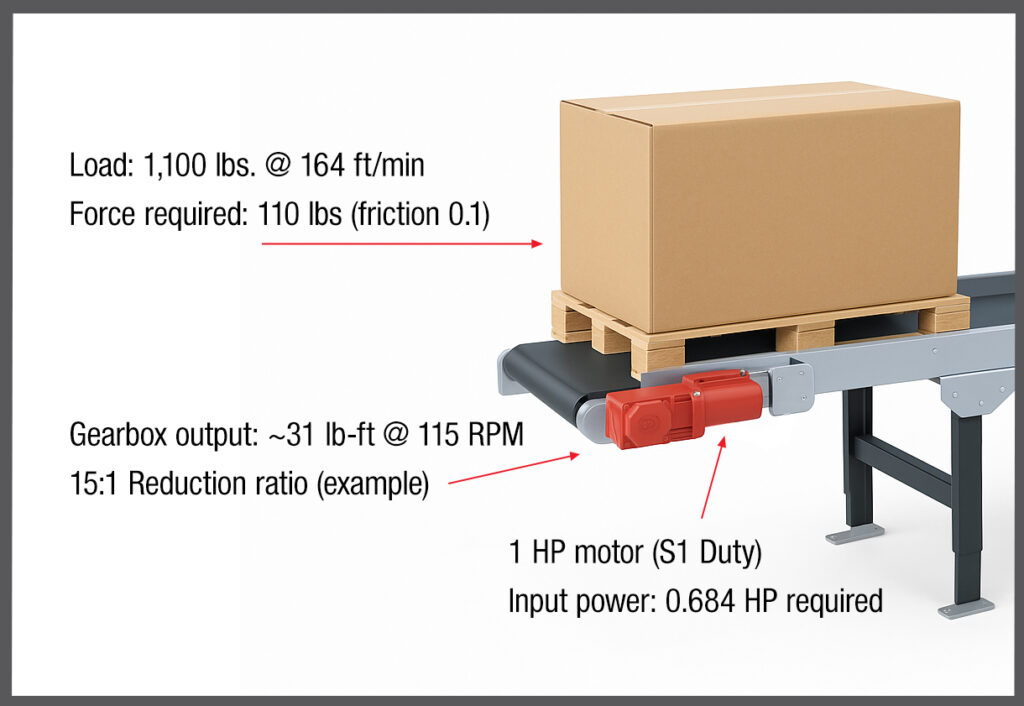

Practical motor example: conveyor system in a warehouse

To illustrate these principles, let’s examine a warehouse conveyor system. A conveyor must move 1,100 pounds of boxes at 164 feet per minute for 8 hours daily. This is an S1 continuous duty application.

Step 1: Calculate power requirements

Determine the F needed

F = load weight x friction factor

Assuming a friction factor of 0.1

F = 1,100 pounds x 0.1 = 110 pounds

Find the power:

Power (hp) =

hp =

Add a safety factor:

0.547 x 1.25 = 0.684 hp

A 1 hp motor rated for S1 duty is ideal for this application.

Step 2: Select the motor

Selecting a high-efficiency motor rated for S1 duty ensures reliable operation while reducing energy costs.

Step 3: Gearbox and variable frequency drive (VFD) integration

- A helical-bevel gearbox adjusts the motor’s output torque to meet conveyor requirements.

- A VFD optimizes speed during lower-demand periods, reducing energy consumption by up to 30%.

Motor efficiency and cost savings

Motors consume a significant portion of their lifetime costs in electricity. For example:

- A 50 hp motor running 24/7 at $0.10/kilowatt hour (kWh) can cost more than $33,000/year in electricity.

- Upgrading to a high-efficiency motor reduces energy consumption by 10%, saving $3,300 annually.

For smaller motors, like a 1 hp motor running 8 hours/day at $0.10/kWh, the annual cost is $262. Switching to an IE3-rated motor can save $26/year. Across a facility with dozens of motors, these savings quickly add up.

Selecting the right motor isn’t just about power ratings — it impacts energy costs, system reliability and operational performance. While the examples here apply universally to motors, gear units and VFDs from any manufacturer. By considering duty classes, load types and integration with compatible components, you can design systems that save money and deliver long-term results.