FMECA is a complex process but can optimize processes

What is FMECA?

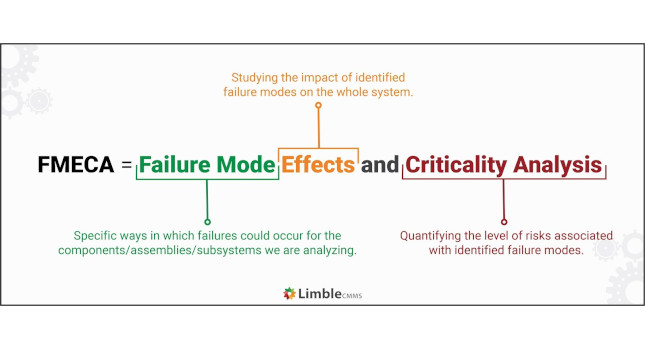

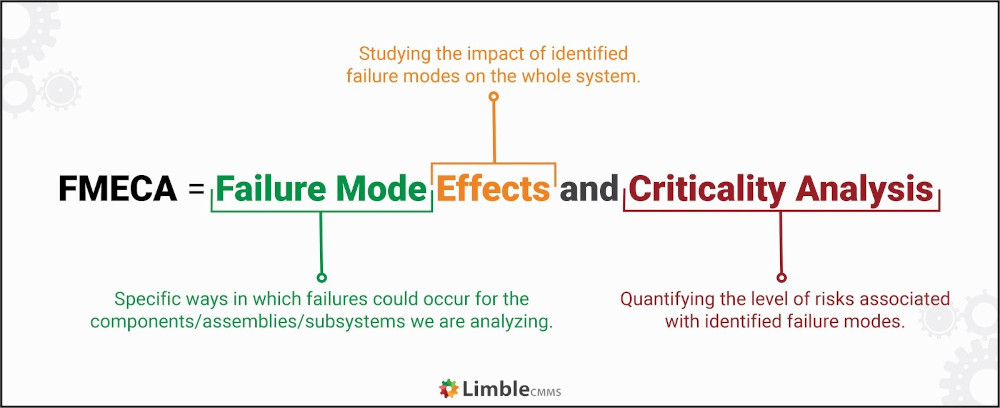

Failure Mode Effect and Criticality Analysis (FMECA) is a reliability design engineering technique that looks into the potential failure modes of any system and analyzes the severity of their impact on system performance. FMECA is an extension of Failure Mode Effect Analysis (FMEA) by adding a criticality analysis to it. The criticality analysis involves classifying and ranking failure modes based on their probability of occurrence and the severity of impact on overall system performance requirements.

FMECA, just like FMEA, is a bottom-up approach that is carried out at the design phase and is intended to not just develop the corrective actions but also to rank them for prioritization. Prioritization of corrective actions is imperative where a large number of assets generally require intervention and the available capital cannot fulfill needs for all assets.

With that being said, FMECA has gained importance over time within various industries, especially within capital-intensive businesses. They are typically subjected to stricter requirements to optimize the process, operations and maintenance with always insufficient resources to execute all of the required corrective actions.

This article outlines a few items that should be considered while performing any FMECA.

How To Perform FREMCA

1. Defining objectives of criticality in FMECA

The main objective of criticality analysis is to contain the risk that any failure poses to the system performance. Before performing FEMCA, it is important to define the risk that is required to be mitigated.

The definition of risk may vary from industry to industry. An event that is considered normal in one industry can be considered risky to another.

For example, specialized explosion-proof enclosures are mandatory for pump assemblies that carry flammable gasoline in an oil refinery. On the other hand, a similar-sized municipal pump carrying drinkable water may have a standard enclosure without posing any safety risk from product leakage. Therefore, the team conducting FMECA must possess strong industry-specific knowledge and tailor objectives accordingly that fulfill their industry’s need.

2. Analyzing quality of data

The availability and accuracy of data play a crucial role in the successful outcome of FMECA exercises. The biases in the interpretation of data have always been a challenge to reliability engineers. Oftentimes, the lack of data on equipment health and performance leads to speculations and opens doors to a decision based on the human experience as opposed to some quantitative decision model.

The best action plan is to streamline all the data points that are needed for the FMECA exercise. The typical data points could include operations and maintainability data, maintenance history picked up from CMMS or maintenance logs, quality defect reports from similar equipment, parts manual and warranty details provided by original equipment manufacturers (OEM).

3. Defining methods of criticality analysis

As we discussed, the criticality analysis involves ranking the failures modes based on the severity of impacts on system performance. The criticality analysis can be carried out in either a qualitative or quantitative manner. The availability and accuracy of equipment data play a significant role in the selection of the method of criticality analysis. The general rule of thumb is to go by quantitative criticality analysis when detailed component-level failure data is available. However, if the asset data is difficult to quantify in numbers, then the qualitative analysis may also give reasonable results.

As the name implies, the quantitative analysis looks at the equipment data that can be quantified such as equipment failure rates, conditional probability data and operating hours. If it is decided to perform quantitative analysis, it is always useful to look at the compilation of infield equipment test data as it can help construct necessary failure rates. For some applications, there may be outside sources or published literature that can be leveraged to obtain general failure distribution data for specific assets.

On the other hand, qualitative analysis is more driven by subject matter expertise (SME) and is used when detailed component level failure data is not available. In qualitative analysis, the risk priority number (RPN) is often calculated through qualitative numerical analysis of design risk.

The components of risks such as probability and impacts are graded on a multi-point scale system. Each point on a scale is given a definition based on qualitative discussions among equipment stakeholders including subject matter experts (SME), reliability engineers, operations, OEM, etc.

4. Integrating FMECA results into CMMS

To ensure the integrity of the FMECA process, it is important to have a closed-loop system that records the outcome of FMECA including priority analysis for continuous improvement. This is because the criticality of equipment depends on variable parameters such as equipment’s health, failure rates and operational conditions that vary throughout the asset’s lifetime.

To record the variance of asset performance over their life cycle, the asset criticality data should be stored and continuously be updated in a Computerized Maintenance Management System (CMMS) or a comparable digital system.

CMMS is a platform that provides a range of benefits to any organization relevant to sustaining the FMECA process. Some of the benefits include tracking of asset failures, automating maintenance tasks, generating work orders, creating interactive performance dashboards and monitoring costs and resources overruns. It also acts as a database of historical data on asset performance that can be used by reliability engineers to predict failures and develop proactive failure containment and asset maintenance regimes.

Final thoughts

FMECA is a complex process, but so are all other maintenance and reliability techniques that have a significant impact on machine performance and reliability. To get the most value out of the process, FMECA should be led by trained professionals or consultants that know common pitfalls and how to avoid them.