If artificial intelligence and machine learning are not yet part of your manufacturing facility’s plans, this Q&A can provide advice.

AI insights

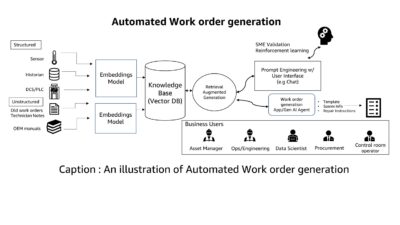

- This Q&A explores how AI and ML are transforming asset management by enabling predictive maintenance, improving risk mitigation and enhancing decision-making through data-driven insights.

- It also addresses key implementation challenges such as data quality, system integration and the evolving role of human expertise alongside advanced technologies.

What challenges and risks do you see in implementing AI-driven asset management solutions and how can these be mitigated?

Nishimoto: Asset managers must ensure they are collecting and managing quality data –– if the inputs are flawed, the outputs will be flawed, too. Asset managers must also ensure the artificial intelligence (AI) systems they deploy are trustworthy. For example, are the insights and decisions AI models produce transparent and explainable? Are they safe and secure? These challenges and risks can be addressed by integrating comprehensive AI governance and AI security frameworks.

Stephens: The biggest challenge in implementing AI-driven asset management solutions is providing quality data to the AI/ machine learning (ML) tools. In practice, this is a twofold problem. The first issue my clients sometimes have is that they do not have enough sensors on the asset and surrounding process to develop a multivariate model. Without enough data points being fed into the AI/ML tool we are reduced basic maintenance alerts from high temperature, differential pressure or vibration –– useful, but usually not enough to apply an AI model to.

The other issue is ensuring that sensor data is accurate and reliable. AI models have difficulty determining whether an anomalous sensor reading is because the process/asset conditions are abnormal or because the sensor is fouled. They will typically assume the asset is in trouble and request maintenance, which can lead to spurious requests that either increase unneeded maintenance activity –– the opposite of our goal –– or erode confidence in the AI/ML tools.

Mackley: Localized AI-based asset analytics is relatively easy to implement, with many barriers to entry. It is contained and easy to deploy. However, as plants ramp up their AI initiatives, they’ll likely start looking into the bigger, more enterprise-level solutions that can be trickier to implement. Doing so requires integrating more systems and managing data sources, which is a much more involved process. AI consumes a lot of data and data silos can make it hard to implement solutions effectively.

Much of that complexity can be solved by engineering solutions with a boundless automation vision of seamless data mobility from the intelligent field, through the edge and into the cloud. When automation systems are integrated by design, project teams don’t need to spend hours and hours creating complex custom integration solutions, which tend to be fragile. Instead, the solutions simply work together, moving contextualized data wherever it needs to go. That makes it far easier to feed the always-hungry enterprise AI solutions with all the contextualized data they need to drive effective analytics.

Cooper: Challenges can arise when companies implement AI-driven asset management solutions that are not created for complex industrial environments. Instead, AspenTech Industrial AI, which is incorporated into AspenTech’s asset health and reliability solution Aspen Mtell, is a combination of AI with domain expertise in engineering fundamentals, asset knowledge and industry experience to provide guardrails, robustness and trusted results. Without purpose-built Industrial AI, companies could face black box challenges in which results can’t be explained or traced back to where the answer came from, among other challenges. Industrial AI directly addresses concerns companies face around the transparency and explainability of regular AI results.

Organizations should also keep in mind that AI can be enhanced with data to model plant equipment and make predictions. By training AI models with asset data and retraining those same models when conditions change organizations can continue to improve their results.

Jones: AI models rely heavily on high-quality, comprehensive data. Inconsistent, incomplete or biased data can compromise the accuracy of AI insights. Ensure robust data management practices, including regular data cleaning, validation and integration from multiple sources.

Integrating AI with existing information technology (IT) infrastructure can be complex, especially with legacy systems. Invest in upgrading IT infrastructure and ensure compatibility between new AI technologies and existing systems.

There is often a lack of skilled professionals who can develop, implement and manage AI systems.

Provide ongoing training and development programs for staff to build AI expertise within the organization.

AI systems can be vulnerable to cyberattacks, which can compromise sensitive data. Implement robust cybersecurity measures, including regular software updates, penetration testing and monitoring for vulnerabilities.

How do you assess the ethical considerations surrounding the use of AI in asset management, particularly in terms of decision-making and bias?

Stephens: While there are genuine ethical concerns regarding the use of AI, most of these concerns relate to the use of AI and possible bias, to make decisions about people, whether that’s about health care decisions for individuals, public funding for groups, hiring decisions, etc. AI use in asset management is generally focused on making decisions about equipment based on equipment operating information. There are normally few ethical concerns with this AI application.

In what ways can AI and machine learning enhance risk management practices within asset management firms?

Cooper: AI and ML can enhance risk management practices at a facility by utilizing data to better understand equipment health and predict when equipment failure is pending. This allows for equipment work to be planned, not only reducing the possibility of production downtime but also reducing the cost of the required maintenance. In addition, planning maintenance work reduces safety incidents by eliminating the emergency work and pressure to get equipment back up and running when working during a downtime event.

How can AI and ML be leveraged for more accurate and timely market forecasting and what are the limitations of such predictive models?

Stephens: Most AI/ML asset management solutions are not physics-based, equipment-specific packages, but statistics-based correlation engines. This technology has the advantage of being easily adapted to new asset types. The technology has the further advantage of being applicable to all sorts of datasets outside of asset health management, including market forecasting. Just as these tools can predict when an asset will stop performing, similar tools can predict future market performance, given the right input dataset. The obvious limitation is that the real world may always throw in a new variable not included in the original training dataset.

What opportunities do you see for AI and ML in enhancing client communication, engagement and personalization?

Stephens: As generative AI is incorporated into both existing AI/ML tools and more traditional tools, personalized information and insights will be available to a much wider audience without specific technical expertise in programming and computer science.

How do you see the role of human expertise evolving in conjunction with the increasing use of AI in asset management?

Jones: Humans will spend less time on rote, manual tasks like data gathering, cleaning and analyzing. These time-consuming tasks will be done through AI. As a first step, humans will move into oversight and governance roles to build trust with new AI systems. In addition, humans will be able to spend more time on strategic decision making and optimization.

Nishimoto: AI will not replace manufacturing professionals. But manufacturing professionals skilled in AI will replace those who are not. This doesn’t mean asset managers and technicians need computer science degrees. AI tools are growing more accessible thanks to Natural Language Processing capabilities. Manufacturing professionals should have a firm grasp of the basics, for example when to deploy these systems, how to maximize their impact and how to minimize risks.

Mackley: With AI, it’s garbage in, garbage out. If users feed AI lots of dirty or irrelevant data or data that leads it down a bad path, they will have struggles with tuning the machine learning to be effective. Expert personnel are needed to ensure data is clean and to ensure outputs are accurate and safe. Teaching and tuning systems takes a lot of time and manual labor.

We expect to see many roles moving from being the subject matter expert on analytics to a role of curating data and ensuring it is clean and consistent. Human roles will evolve, but they will still be critical for the foreseeable future. Roles may morph to help incorporate AI as a partner, but the need for human interaction is not going away.

Stephens: As AI asset management evolves, humans will take on more of a supervisory role of training AI models, ensuring AI systems are being fed reliable information and prioritizing recommended actions. Humans will also still be needed to perform most of the field maintenance activities for the foreseeable future.