Share your knowledge and stories about improving operational efficiency.

AI insights

- A recent Plant Engineering study found that 28% of respondents plan to implement artificial intelligence (AI) within the next year to improve operational efficiency, whether through automation, predictive maintenance, digital twins or supply chain optimization.

- AI is also transforming workforce management, from hiring and training to customer service, making it a critical tool for addressing industry challenges.

A recent “state of the industry” study conducted by Plant Engineering showed that 28% of respondents plan to implement artificial intelligence (AI) in the next 12 months to improve operational efficiency. But what does that look like?

It’s different for each plant, and difficult to put a “best practices” stamp on a plan. Implementation generally requires a variety of systems to talk to each other, which may mean updating portions of a plant’s software, sensors or other data-collection tools.

Achieving operational efficiency could mean improving automation with AI, such as tapping into advancements in machine learning, cloud computing and natural language processing. It could also include automation as part of a more holistic approach to managing a manufacturing plant.

Automation in the form of robots is also a collaborative way to use AI. By incorporating these collaborative robots — or cobots — manufacturers can automate aspects of existing product manufacturing or even add new production options.

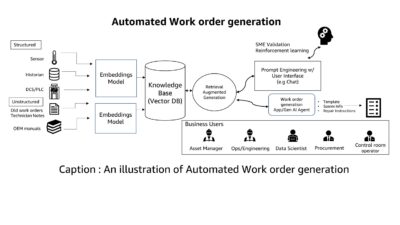

AI can be added to a plant’s predictive maintenance strategy, reducing the need for a break-fix approach. Plant managers can use data to review historical patterns and predict when or where a failure might occur. This relies heavily on sensors and other tools to collect information.

Digital twins offer a digital replica of physical systems to allow engineers to conservatively simulate processes within a plant, allowing for process optimization that retains the ability to test new options without disruption. This is a next-level way to achieve operational efficiency and may require consultants or system integrators.

Depending on the size of the plant and the procurement volume, supply chain management can be brought to a new level with AI. The amount of data AI can comb through helps procurement accurately obtain products at the lowest price and correct time. Sourcing and negotiations can be handled by AI, too.

Customer service can be tackled by AI to ease operational efficiency, with basic questions fielded by chatbots and more complex questions managed by humans. By coordinating production schedules and inventory with customer service, solutions can be reached more easily, keeping customers happy.

Finally, recruiting is one of the toughest workforce challenges for plant engineers. In the same study, 63% indicated they had difficulty hiring skilled technicians, and 22% said they struggled to retain experienced employees. While some may shun using AI, its incorporation into the hiring process, training or even knowledge retention can be invaluable.

Would you like to share your knowledge on any of these topics? We will be covering them over the next several months, so please contact me to share your story.