Ed Silva from Flowserve Corporation answered additional questions on topics such as auto calibration, HART modules and more.

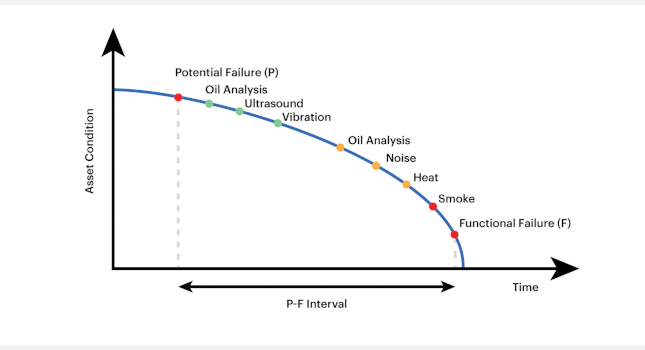

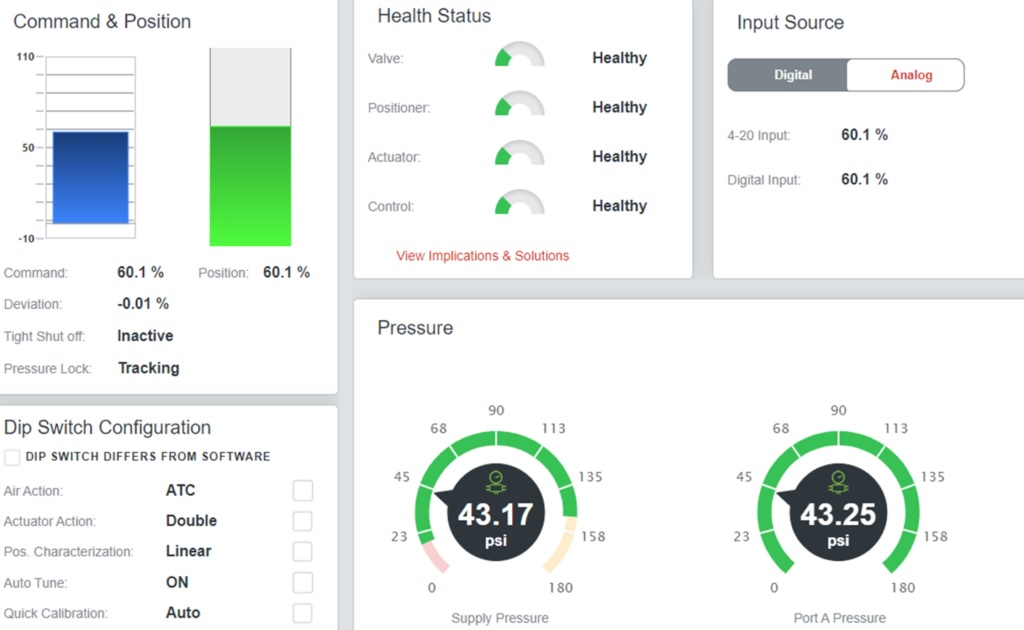

Control valves positioners have evolved exponentially in recent years. Positioners now can provide a full stack of valve, actuator, control and positioner diagnostics, but these diagnostics are different for each OEM vendor and hard to understand the severity of each alarm and of each device to know when it is a nuisance alarm or when to act.

Ed Silva, director of engineering, smart products, Flowserve Corporation, answered additional questions on topics such as auto calibration, HART modules and more.

Click here to watch the webcast on-demand.

Question: How does auto calibration play a role in enhancing the performance and reliability of control valve positioners when connected to the cloud?

Answer: The connection to the cloud is read only, therefore all commands to perform auto or manual calibration it is not possible through the cloud connection. However, by having the positioner connected to the cloud and by having the manufactory monitor the control valve performance, the manufactory could help the customer to identify when the positioner has performance issues, and how to calibrate or tune the positioner for better performance. Also, by having the monitor data, we can better identify root cause of under performance and guide the customer to a possible solution other than an auto or manual calibration.

Question: For the wired communications option, what is the function of the HART Expansion Module?

Answer: The HART expansion module function is to establish communication with the field devices to read its data for monitoring, in case the customer does not want to use the DCS/AMS OPC Server connection or there is not a DCS/AMS available at the plant.

Question: Although not an issue, can the system determine slipstick on a valve?

Answer: By monitoring the valve friction, we can identify “high friction,” which can cause loop oscillations, poor position control, jerky motion, or valve slipstick. All those symptoms can be caused by build-up from the process on the stem, trim or seat, by a failing bearing or guides in the valve or actuator, galling of the trim or stem, excessively tightened packing, linkages, or other valve or actuator mechanical issues. Indirectly, the system can determine slipstick by monitoring the valve friction.

Question: How well does this technology translate to motor-operated gate valves?

Answer: The technology is agnostic to any register motor operated valve (MOV) as long as the device is a certified device with the Fieldcomm group having a device description (DD).

Question: #3 failure type states “air leaks” as a failure mode. Does this mean that the technology for hydraulic actuated control valves doesn’t yet exist? If not, then will such technology be developed? By when do you expect that to happen?

Answer: The technology monitors the device failure modes, independent of the type of driver module (pneumatic, electrical and hydraulic), if the device provides hydraulic failure modes, we can also monitor it.

Question: Is the Logix3800 positioner a replacement for the LogixMD? What features does it add?

Answer: It is our latest released positioner. I could write pages on the list of extra diagnostics alone. Here are a few generic differences it provides:

-

Modular design

-

More sensors for more diagnostics

-

More tolerant to dirty air

-

Contactless feedback and more.

Question: Does the cloud service contain algorithms that perform fault diagnostics as soon as a deviation from normal operation is detected?

Answer: For pumps and seals, the cloud service contains algorithms that perform fault diagnostics. For positioners, the diagnostic is in the device and the could monitors that information direct from the device. As we collect more positioner data, we’ll be adding more diagnostics to the cloud from what we learn from the cloud trend data.

Question: Is there a subscription like service for remote monitoring? How much per point?

Answer: The service is a yearly subscription service and the price will change depending on many parameters (subscription length, number of devices, cloud or on-premise, wireless or wired connection).