The new revised edition is one reference book every plant engineer should have. Click above to read a review and to order.

Plant Engineer’s Handbook edited by R. Keith Mobley. 1189 pp, hardbound. Butterworth-Heinemann, 225 Wildwood Ave., Woburn, MA 01801-2041; phone 781-904-2500; fax 781-904-2620; bh.com. $125.

To order, please click here

Review by Richard L. Dunn, Editor, Plant Engineering

Every plant engineer’s bookshelf should contain at least one basic engineering reference. And if you’re only going to have one, Plant Engineer’s Handbook is a good candidate. This volume is a completely revised edition of Plant Engineer’s Reference Book, which was published about 10 years ago.

As chief editor of the handbook, Keith Mobley has done a masterful job of assembling the contributions of 40 contributors into 64 chapters that cover the entire plant engineering function from definition to technology to management. In fact, this handbook stands out from most other engineering handbooks by including information on such issues as insurance, finances, and maintenance management in addition to the engineering knowledge plant engineers require.

In his preface, Mobley says, ”In compiling the initial suggested guidelines for each of the contributions, I posed the questions to myself what Information and assistance had I found difficult to locate during over 30 years as a plant engineer responsible for plants throughout the world and how could it be best presented to assist others in their profession.”

The contributors have succeeded admirably in meeting the challenge. Every page contains practical information and advice.

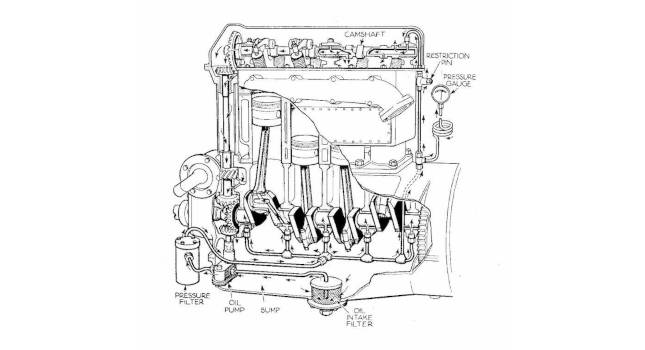

A proliferation of diagrams, charts, and tables add value to the text. And numerous equations facilitate working out real-world problems.

A word of warning: The handbook is intended for an international usership and was, in fact, written by experts on both sides of the Atlantic. Thus, there are many references to practices and standards in the U.K. as well as the U.S. This inclusion, however, in no way detracts from the book’s usefulness.

Excerpt:

”The single-stage, single-valve turbine is the simplest option. Such a machine is suitable for applications requiring powers up to 300 kW, steam conditions up to a nominal 115 bar, 530°C and rotational speeds below 5000 rev/min. A typical machine is shown in Figure 15.37, characterized by an overhung rotor mounted on a stiff shaft capable of being accelerated from cold to operating speed within 10 s. The efficiency is low, but so is the cost of the installation. For higher powers and for a wider range of steam conditions incorporating all combinations of backpressure, condensing and passout systems, the multistage axial flow machine is the natural choice.”

From the publisher, Butterworth-Heinemann:

This handbook is packed with indispensable information, from defining just what a plant engineer actually does, through selection of a suitable site for a factory and provision of basic facilities (including boilers, electrical systems, water, HVAC systems, pumping systems and floors and finishes) to issues such as lubrication, corrosion, energy conservation, maintenance and materials handling as well as environmental considerations, insurance matters and financial concerns.

One of the major features of this volume is its comprehensive treatment of the maintenance management function; in addition to chapters which outline the operation of the various plant equipment there is specialist advice on how to get the most out of that equipment and its operators. This will enable the reader to reap the rewards of more efficient operations, more effective employee contributions and in turn more profitable performance from the plant and the business to which it contributes.

The editor, Keith Mobley and the team of expert contributors, have practiced at the highest levels in leading corporations across the USA, Europe and the rest of the world. Produced in association with Plant Engineering magazine, this book will be a source of information for plant engineers in any industry worldwide.