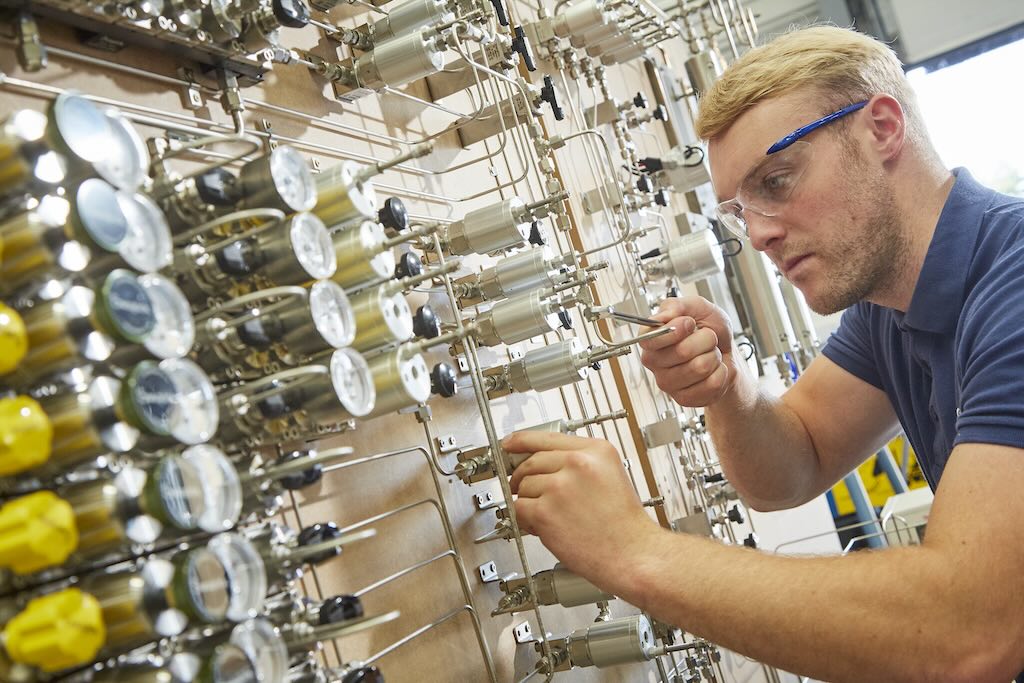

Specifications for hydraulic hoses are critical; the replacement hose needs to have a working pressure rated at the normal operating pressures set at the factory to help ensure worker safety. Best practices and four tips on how to make a hydraulic hose are highlighted.

Most of the equipment being manufactured domestically or imported today for hydraulic hoses are fairly complex. Many times, when the machine is down because of a bad hose or fitting, the machine operator or individual that is responsible for getting the machine repaired, doesn’t know the operating pressures and other specifics of the equipment.

Specifications for hydraulic hoses are critical. The replacement hose needs to have a working pressure rated at the normal operating pressures set at the factory. If the new replacement hose or fitting develops a pinhole or ruptures because of the normal operating pressures exceeding what the SAE or DIN Standards are, the hose could cause serious injury or death.

Due to these dangers, it is always a good decision to purchase hoses and fittings from a reputable supplier. Certified technicians on staff have training and experience which can help guide the customer on the product that would best fit their needs, while also reducing the chances of an accident possibly occurring.

Anytime a hose is going to need to be replaced, the STAMPED criteria needs to be applied if possible:

-

S – Size: What is the inside diameter of the hose? Sometimes the outside diameter is also critical information depending on the environment and physical constraints of the assembly.

-

T – Temperature: What is the hose assembly’s working environment? What is the assembly conveying? Hose materials will break down quicker if used in improper ways or under conditions it is not rated for, increasing failure rate and potential damage.

-

A – Application: How will the hose be used? What will be asked of it? How much will it have to bend? Will it be exposed to corrosive or destructive chemicals or motion?

-

M – Media: What type of material being conveyed through the inside of the hose?

-

P – Pressure: What is the normal working pressure? What are the highest possible pressures the hose assembly will be exposed to? A properly configured hose assembly will have a 4:1 burst-pressure-to-working-pressure rating.

-

E – Ends: What fittings will the assembly require? What thread type, material, or angle will the job require?

-

D – Delivery: Delivery is for packaging, testing, and delivery requirements. Does the hose need to be pressure tested? Is there a specific packaging need to ensure the hose assembly arrives as it left the distributor? How quickly do you need your hose assembly?

Four tips on how to properly make a hydraulic hose assembly

-

The hose needs to be cut the proper length for the application.

-

The proper insertion depth of the fittings needs to be marked on the outside of the hose.

-

Hose fittings should be secured properly on each end of the assembly. If fittings are crimped onto the assembly, the outside crimp diameter needs to be measured with a set of calibrated calipers. That measurement needs to be compared to the crimp specification chart provided by the hose and fitting manufacturer. This procedure is critical and any discrepancy needs to be questioned.

-

The assembly then needs to be cleaned and both ends capped, so that the inside will stay clean until the hose is installed.

The quickest or cheaper alternative might be more appealing in the moment, but for long-term dependability, it’s the quality that counts. Following all of the steps highlighted are very important to follow so everyone can continue to be productive while staying safe.

Brian Crisp, territory manager, Cross Co. This article originally appeared on Cross Co. Hose & Fittings blog. Cross Co. is a CFE Media content partner. Edited by Chris Vavra, production editor, Control Engineering, CFE Media, [email protected].