Message queuing telemetry transport (MQTT) and industrial edge devices remove systemic limitations, communicate more data and improve system security for IIoT implementations.

Learning Objectives

- Message queuing telemetry transport (MQTT) and industrial edge computing devices can help get information to users faster.

- Three IIoT examples of MQTT and edge devices in different industries are highlighted.

- Cybersecurity and data protection are considered as vital as getting the information to the users who need it most.

IIoT implementation insights

- Message queuing telemetry transport (MQTT), combined with industrial edge computing devices, can improve data transmission and asset management in many different industries.

- The IIoT’s main goal is providing data where it’s needed and giving the user the insights needed regardless of the delivery device.

With the Industrial Internet of Things (IIoT), the goal is to get useful data from field devices and legacy systems and move that data where it’s needed–for asset management, for regulatory reporting, for efficient maintenance, for making business decisions. But putting together an IIoT system for doing so is often complicated, involving many operational technology (OT) and information technology (IT) devices, protocols and software.

System integrators are increasingly finding that two tools can simplify IIoT implementation: the message queuing telemetry transport (MQTT) communications protocol and industrial edge devices.

MQTT (formerly IBM’s MQ Telemetry Transport) is a publish-subscribe (pub-sub) protocol originally developed for the oil and gas industry. In contrast to a typical client-server architecture, pub-sub reduces connections and network traffic. Each client initiates communication to a central broker/server and then publishes data, subscribes to data or does both.

The broker/server does not store data; it accepts and forwards data packets as required. Network traffic is reduced overall, because data is communicated on a report-by-exception (RBE) basis rather than at regular intervals.

Industrial edge devices are designed to withstand harsh industrial conditions but still act like a PC in many ways. They communicate using OT and IT protocols, which often include software tools to make data acquisition and communication easier. They also provide built-in security tools to make data exchange safer.

Consider three system integration (SI) IIoT implementation projects to see how these tools together can help:

-

Remove systemic limitations, especially for data from remote equipment

-

Communicate more data, at the frequency you need, without overwhelming the network

-

Improve system security.

Building secure wastewater management in the cloud for IIoT

For years, Waterford Township has shared data among its water/wastewater core applications, including geographic information systems (GIS), asset management systems (AMS), enterprise content management (ECM), and supervisory control and data acquisition (SCADA). But long-standing systemic limitations had them looking for newer technology.

With over 90 controllers on its network, the polling mechanism combined with the limited bandwidth of the radio network meant site data updated only every 3-5 minutes. If a lift station ran briefly between polling cycles, reporting gaps and undetected issues caused problems. And each I/O point added to the system made the latency worse.

It seemed clear to Waterford that MQTT could be a solution, reducing bandwidth usage while making sure data is reported. Instead of cyclic polling, MQTT would follow a strict report-by-exception publishing rule. Field devices and other MQTT network clients would send data on their own, but only if a monitored value changes.

“We have many lift stations that will spend most of their time sitting,” said Russell Williams, director of public works. “Why transfer data all the time?”

To help them execute their IIoT implementation vision, Waterford DPW engaged Perceptive Controls, a Michigan-based system integrator. They chose an edge controller because of its built-in MQTT capabilities, familiar programming tools, and lifetime I/O warranty. After experimenting with SCADA packages, they decided on one with MQTT integration, including the ability to serve as an MQTT broker. Establishing communication was straightforward with the right tools.

“It kind of happens automagically,” said Kevin Finkler, software engineer at Perceptive. “You basically define a few parameters [in Ignition] to set up the broker.”

The controller’s MQTT infrastructure has reduced field updates from multi-minute cycles to sub-second event-driven publications. With that kind of speed, Waterford never misses a system action or alarm notification. And with analog I/O deadbanding in each EPIC, they’ve also reduced bandwidth consumption, allowing Waterford to publish additional data that wasn’t possible before.

Waterford and Perceptive deployed the new system in the cloud on Amazon Web Services (AWS). Perceptive can update controllers over the air, reducing travel time and speeding project development.

For security, they configured the AWS firewall to accept traffic only from the new edge controllers and specific Ignition clients in Waterford’s and Perceptive’s offices. They installed a client SSL certificate on each controller, so the SCADA could authenticate and encrypt the connection. In addition, every authorized user must create strong passwords to access any edge controller or SCADA client in the system and every user login is tracked and reported. All this gave Waterford DPW the data they needed when they need it.

Reducing costs, improving safety in natural gas production using IIoT

Automation and data acquisition for assets located over a broad area isn’t easy, and oil and gas installations are prime examples of remote assets.

“Most automation companies don’t understand the network piece,” said Dan Arbeau, CEO of netDNA in British Columbia. Arbeau’s customer, New Wave Energy Services, needed help with a major project in the Permian Basin in Southern Texas, which was managing water at hundreds of drilling sites.

In an industry with widely separated and changeable operations, mobility is essential. New Wave designed large trailer-mounted units for water transfer, typically with four 500-800 HP pumps with 12-in. diameter inputs and turned to netDNA to automate them. Each unit includes a diesel generator and pumps, controlled by a genset controller that talks Modbus/TCP. Arbeau added a edge processor and I/O modules on each trailer for additional IIoT automation:

-

Analog inputs monitor discharge levels and suction.

-

Digital inputs monitor flowmeters.

-

Mechanical relay outputs open and close pumps via the genset controller.

The controller also pulls data from the genset controller, including RPMs and associated telemetry, and publishes it to a central MQTT broker/server.

netDNA also automates water pits and tanks, monitoring levels, controlling pumps to avoid spills, and monitoring air quality and hydrogen sulfide (H2S) levels. H2S is flammable and potentially deadly if inhaled. Instrumentation and automation help keep employees safe and improve environmental conditions.

At the pits and tanks, a self-contained gateway for wireless sensors was installed. The gateway talks Modbus/TCP to a local controller, which publishes data that includes 15 telemetry data points and 10 stop, E-stop and other commands. Production data also is tracked and historized in case a spill or issue occurs.

The edge controllers on each trailer, tank, or pit publish data to the MQTT broker, and other edge controllers subscribe to the data. For the broker, a hosted secure MQTT server was used.

Each controller contains its own device firewall for data security. The data the edge controller publishes is device-originated behind its firewall, so no inbound port modifications to the firewall need to be made. Once the controller makes the connection with the broker, any subscribed return data is received securely over the same connection.

The system worked well for remote, wireless control. Multiple pumps respond to sent commands within a second. To save bandwidth, netDNA sent data in tables instead of individual data points whenever possible.

With modern IIoT tools at his disposal, Arbeau spent only three weeks from initial hardware design to having a full system ready for pump control.

“Some engine and pump companies are hungry for automation. Some have systems, but they don’t communicate with each other,” Arbeau said. The edge controller makes them talk, and MQTT provides efficient data communication for the mobile and remote assets.

IIoT: AI-powered vision system connects manufacturing data to the cloud

California-based Intrinsics Imaging offers customers machine vision systems with machine vision software. Instead of programming specialized cameras to inspect manufactured goods for defects, the machine vision software works with any IP camera.

A recent customer wanted to integrate the machine vision software directly into process controls in two production lines moving discrete boards at high speed:

-

The primary line cuts large sheets of raw material to size. Cut sheets need to be inspected for excess moisture as well as dents, debris, and scratches as small as a grain of rice. Hundreds of product types go through this conveyor.

-

The second line monitors milling quality, looking for chipping along the edges.

The customer also wanted a pass/fail I/O signal that integrated directly into the programmable logic controllers (PLCs) that reject material. Bypassing the SCADA and going directly to PLC action would simplify integration and reduce latency.

Intrinsics CTO Eric Cheng said, “I wasn’t sure what kind of device could provide a physical interface to our cloud-based system and also satisfy our technical and operating requirements.”

Cheng said the machine vision system’s communication infrastructure is built on MQTT. “It’s usually new for customers, but it’s typically the best way to meet their performance and security requirements. [MQTT is] lightweight and low-latency… and it doesn’t require us to reach into their network from the outside.”

The I/O device Cheng needed would have to tolerate an industrial environment, integrate with the machine vision software’s existing software stack, and operate with minimal latency. Just five seconds were available for detection and rejection after a video capture was sent to the machine vision software.

The edge I/O had the industrial build Cheng needed, as well as a Linux core and multiple options for MQTT. Cheng also appreciated its web-based interface, Node-RED runtime, and embedded firewall – no need for a Microsoft Windows-based PC.

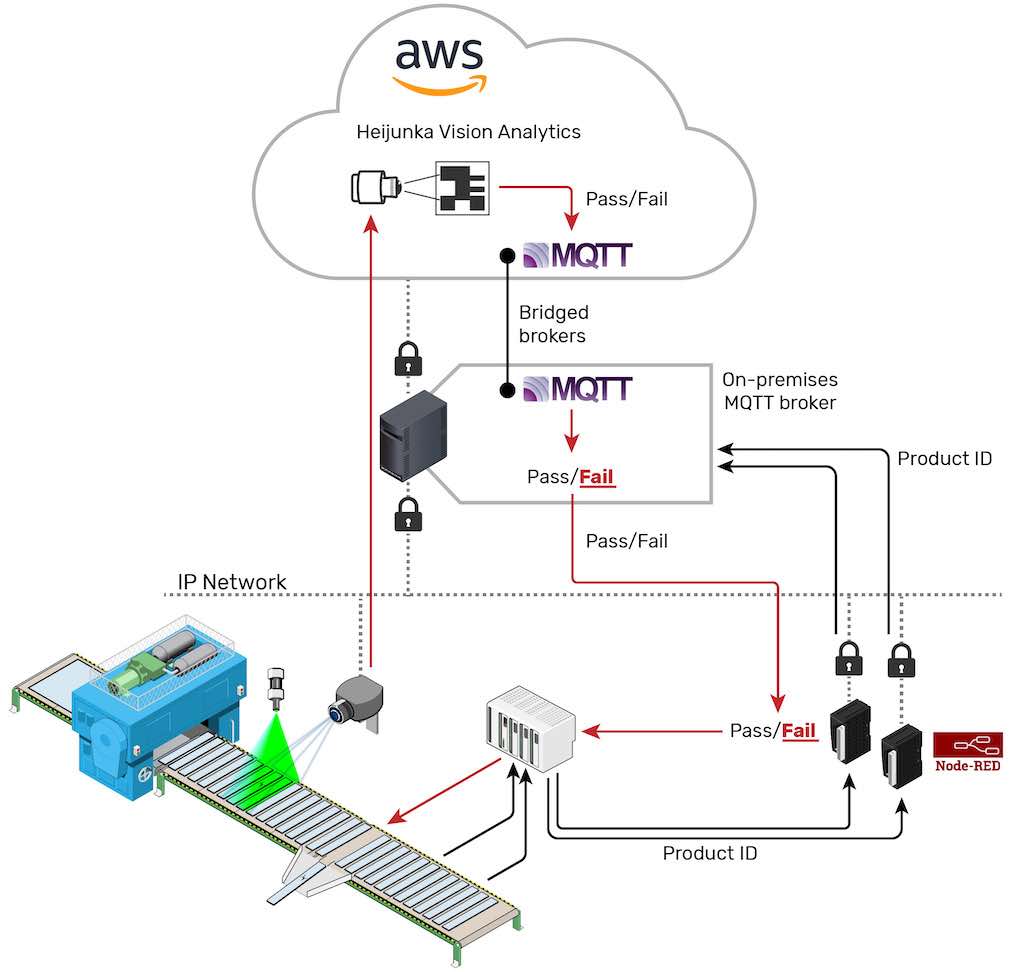

For security, Intrinsics built an isolated network at the customer’s facility to connect cameras and edge I/O modules to an on-premises MQTT broker. A separate network connects that broker to the internet for video streaming to the machine vision software and data exchange with a cloud MQTT broker, both running on Amazon Web Services (AWS). The two brokers are bridged to exchange data, so clients on both systems can use it.

Each edge I/O module makes an encrypted connection to the local broker, which has only port 8883 open for secure connections. The local broker acts as a firewall for the OT side of the system while still allowing data to be exchanged with the machine vision software in the cloud.

Production line PLCs encode the product ID for a specific part and send it through the controller, which uses Node-RED to publish the data as MQTT topics. The machine vision software decodes the product ID and sets the algorithms for that product, then publishes quality indicators to the MQTT broker in the IIoT implementation.

The edge I/O module subscribes to the quality data via Node-RED and indicates the pass/fail decision through one of its relay outputs. The production PLCs watch these outputs and trigger a physical rejection if needed.

The customer has been automatically rejecting defects for several months now, and the system provider confirms a round trip time, from measurement to result, of less than two seconds.

“We were under the gun to do this [project] quickly,” Cheng said, “but we got it figured out in less than a month… Now we can provide a direct physical interface to low-level automation systems.”

Benson Hougland, VP of marketing and product strategy, Opto 22. Edited by Chris Vavra, web content manager, CFE Media and Technology, [email protected].

MORE ANSWERS

Keywords: message queuing telemetry transport, edge computing, IIoT

ONLINE

See additional IIoT and Industry 4.0 stories at IIoT, Industrie 4.0

Perceptive Controls | Leader in Controls & Insight

CONSIDER THIS

Have you used MQTT and edge computing in your facility and what were the results like?