Lubricant is the lifeblood of heavy machinery and oil sampling can help engineers get the most of their lubricant’s utility.

Learning Objectives

- Understand the causes of lubrication breakdown.

- Learn about the process and benefits of oil sampling.

- Review the contents of an oil sample report and what can be identified in an oil sample analysis.

Oil sampling insights

- Oil sampling can help engineers keep their compressed air systems running efficiently by ensuring the lubrication hasn’t gone bad. If it does go bad, it can lead to severe repair issues or downtime.

- Proper oil sampling techniques such as good data recording and ensuring the lubricant is at a proper temperature can help the engineer get the most accurate assessment on how the lubricant is performing.

Lubrication is a crucial element in the efficiency and life expectancy of any piece of equipment with moving parts. Lubricants have many functions, and their main purpose is to form a protective barrier between the metal surfaces of critical machine components. Over time, the lubricant in the machine breaks down to where it can no longer protect the machine. At this point, the lubricant must be changed and the machine must be filled with a fresh batch of lubricant. This is often referred to as the drain interval.

Optimizing the lubricant’s drain interval is not an easy task without the proper tools and knowledge. The safest — and most accurate — way to monitor and analyze the lubricant’s drain interval is oil sampling. Oil sampling is analogous to a person going to the doctor and getting bloodwork completed. It is a snapshot of the oil’s health in the machine at that moment.

Done routinely, oil sampling is one of the best predictive maintenance tools a service manager can use to keep the compressor running reliably. To some, oil sampling may seem like a complicated process. With any luck, this article provides some helpful insights into the oil sampling process from filling the sample bottle to what to look for on the sample report.

Choosing the right lubricant is critical

Before trying to maximize the lubricant’s drain interval, it is important to understand how to select the best lubricant for the compressor and why lubricants degrade overtime. Most of the time, lubricant selection is determined by the manufacturer of the equipment. If it’s the engineer’s choice, selecting a high-quality lubricant provides a strong foundation for the life of the compressor. A poor lubricant choice can cause premature wear and increased temperature and pressure on internal compressor parts resulting in lower efficiency and decreased life span.

The two primary criteria for selecting the best lubricant are viscosity and function.

Viscosity is the most vital characteristic of any lubricant. Viscosity is a measure of a lubricant’s resistance to flow and is often referred to how “thick” or “thin” the oil is. If the viscosity is too high, the lubricant will not flow though the compressor properly causing high temperatures and wear.

A lubricant with a low viscosity will prematurely degrade and will not create a strong enough barrier between moving parts. The proper viscosity is scientifically calculated by measuring and determining various factors such as bearing clearances, internal temperatures and pressures.

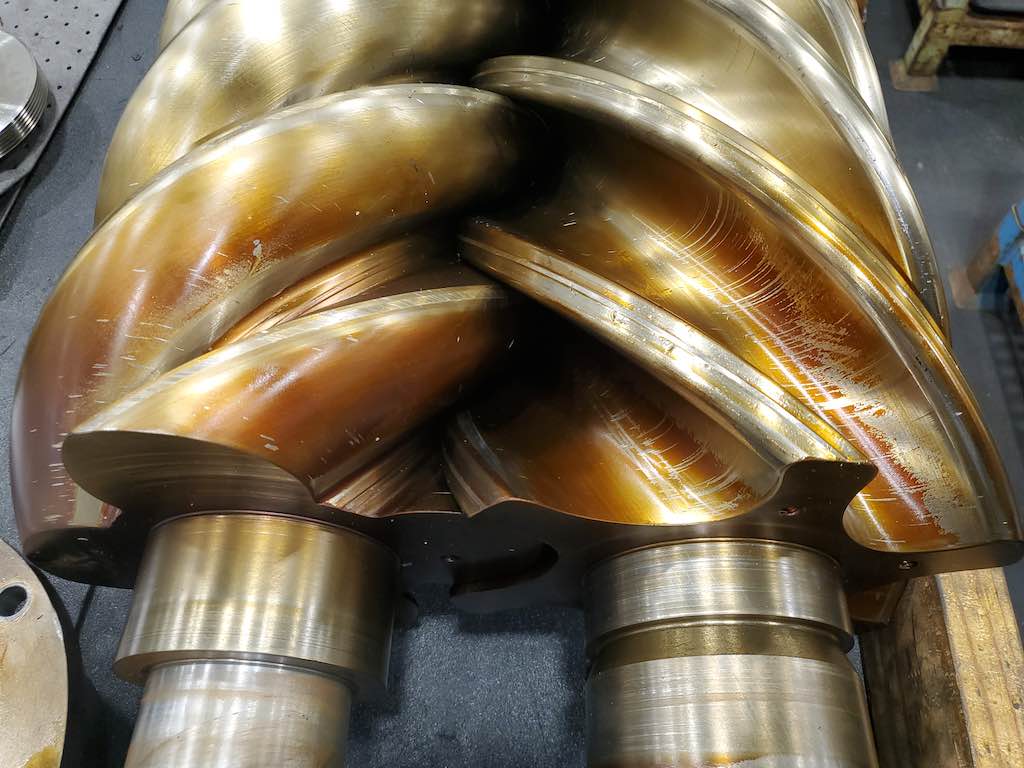

The second primary factor of selecting the best lubricant is function. The main function of any lubricant is to reduce friction between moving surfaces. However, equipment such as an oil flooded rotary compressor demand the lubricant to serve multiple purposes including lubricating the bearings, creating an airtight seal and removing the heat generated from compression. Other specialty lubricants are formulated to hold contaminants in suspension, clean or strip metal surfaces of any past varnish or provide cushion between components under high stress.

Not all lubricants are created equal and unexpected breakdowns are expensive. Always begin the lubricant selection process by referring to the equipment’s service manual and selecting either the recommended lubricant or a high-quality equivalent product.

Main lubricant breakdown causes

When a lubricant reaches the end of its useful life, it is no longer capable of protecting equipment components. Users are often searching for what is causing the lubricant to breakdown. The answers are quickly identified when analyzing an oil sample report.

Oxidation is the primary mechanism of lubricant degradation and is the reaction of the lubricant molecules with oxygen. Oxidation creates several negative effects such as increased oil viscosity, acid formation and varnish. The chemical reaction between a lubricant and oxygen cannot be avoided, but the progression can be delayed by using the correct lubricant with the appropriate additives.

Contaminates such as moisture, dirt and residual used oil also can influence a lubricant’s degradation rate. Contaminated lubricants can be a significant contributor to related equipment failures. Solid contaminates are abrasive and score metal surfaces. Moisture will alter the load handling ability of a lubricant. Moisture also increases the rate of oxidation.

Residual used oil left in the compressor from the last oil change will increase the rate of lubricant degradation. It is important to drain as much used oil out of machine as possible before adding fresh oil into the system.

Additive depletion is another cause of degradation. Lubricant additives are chemical compounds that improve the lubricant performance. Most additive packages in lubricants are designed to be sacrificial and are used up during the life of the lubricant.

Four oil sampling best practices

The most effective predictive maintenance programs include an oil sampling program to monitor lubricant conditions and identify any potential threats to the equipment. Oil sampling helps maximize asset reliability and bring cost savings to a company’s bottom line. To receive the most out of an oil sampling program, it is valuable to implement a few best practices in the oil sampling technique.

-

Proper sampling techniques include running the compressor up to normal operating temperature before taking the sample. An oil sample should never be taken while the lubricant is cold. This will help to ensure the oil is well mixed with no idle particulates or water.

-

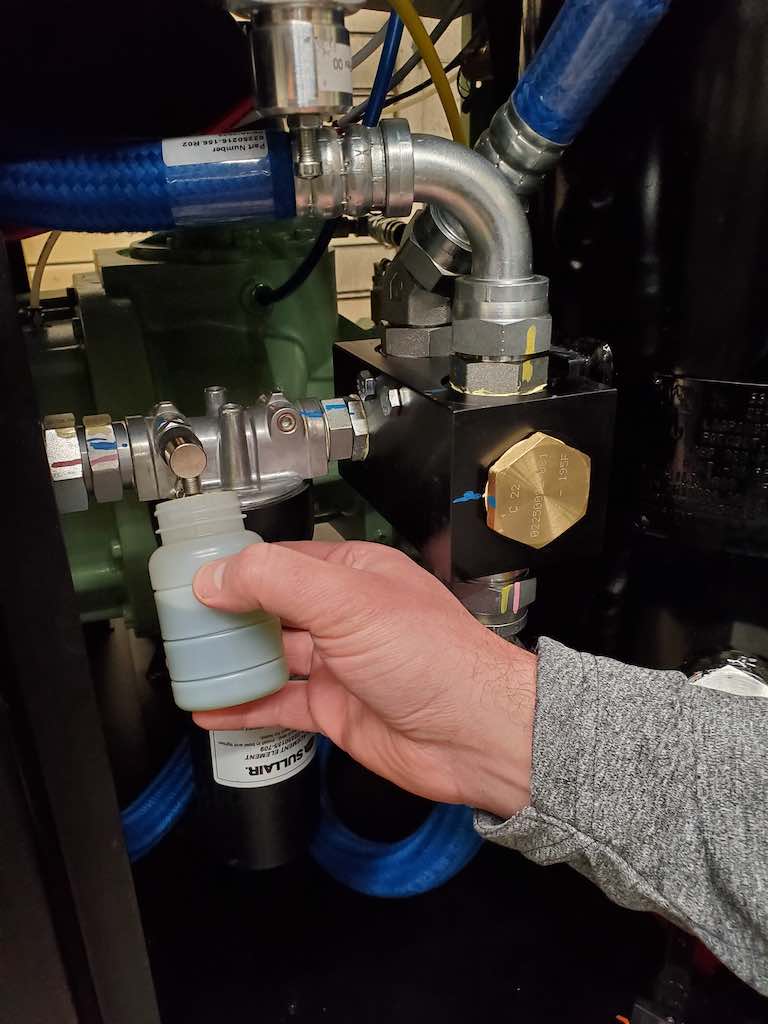

Preparing a clean area for the sampling is also a best practice. The fluid sample valve must be clean and free of debris before draining the sample into a clean new bottle.

-

The most important step in the oil sampling process is recording all the data about the sample. To aid in the oil sample report analysis, it is best to record accurate information about the sample such as type of lubricant, hours on oil, compressor hours, serial number of the machine and the date of sample.

-

Consistent oil sampling frequency is vital to any good maintenance program. Predicting a failure with oil analysis is about having the opportunity to witness the root causes or symptoms as they develop. Consistent sampling frequency allows the maintenance professional to investigate historical trends and monitor how the lubricant is responding to its environment over time.

Once the sample is taken, it should be sent for lab analysis as soon as possible. Prompt analysis can provide time to act before expensive repairs or unplanned downtime occur. Maintenance professionals can determine what action is needed once the oil sample report is received. The next steps are not always crystal clear from the oil sample report, but looking for a few simple results can help provide a suggested course of action.

Sample analysis 101

Once in the lab, viscosity is the most common test run on lubricants because it is the most important property. If a lubricant does not have the right viscosity, it cannot perform its functions properly. Viscosity is measured with a viscometer, which consists of a constant temperature bath and capillary tubes. Industrial oils are identified by their ISO viscosity grade (VG). Most common ISO viscosity grades for an air compressor are ISO VG 32 and ISO VG 46. The viscosity of the oil sample is compared to the lubricant’s baseline or the test results of a virgin sample of the lubricant. An increase in viscosity is often caused by oxidation or contamination. If the viscosity of the lubricant is outside the limits set by the laboratory, change the lubricant in the machine immediately.

Elemental spectroscopy is the examination of concentration of the expected and unexpected elements in the oil. Elemental spectroscopy is a test used to determine the parts per million of wear metals and lubricant additive metals in the oil sample. Wear metals are those metals that originate from an internal component of the compressor. The oil sample is “burned,” causing light to be emitted at frequencies unique to each element being measured. The intensity of light is measured and converted to a concentration, typically parts per million. Wear metal analysis is used to detect machine wear at early stages before the problem becomes catastrophic. Typical wear metals include iron, copper, lead and tin, all of which are common in shafts, gears and bearings.

Acid number, which is commonly referred to as total acid number, is an indicator of oil condition. It is useful in monitoring acid buildup. Oil oxidation causes acidic byproducts to form. High acid levels can indicate excessive oil oxidation or additive depletion and can lead to corrosion of internal compressor parts. Acid number is tested by titration to detect the amount of acidic byproducts in the oil sample. Acid number should increase gradually over the useful life of the lubricant. A sudden increase indicates the lubricant is no longer capable of resisting oxidation.

Moisture is one of the most destructive contaminants faced by maintenance professionals. Overall tolerance of moisture depends on the lubricant and application. It is generally beneficial to keep moisture contamination at the lowest level possible. Moisture can be prevented by running the compressor at the recommended operating temperature.

Physical contaminants are also reported on the oil sample report; they are abrasive and are detrimental to internal compressor parts. Particle counting is considered an important proactive tool. Particle size and number are counted by an automated particle counter. The results of the particle count are reported out as an ISO cleanliness code. An ISO cleanliness code consists of three numbers which provide a standard for the amount and size of the particles in the oil sample.

Every laboratory has its own format and conventions for the oil sample report, but it should always state the machine and lubricant condition. Interpretation of oil analysis requires attention to detail and persistence. The professionals at the laboratory are a good place to start with any questions. Equipment manufacturers also have experts on staff that can answer questions and provide insight about the machine and the lubricant properties of interest. With the information provided by the sample report, the engineer can identify and rectify any issues before they become a costly headache.

A compressed air system is not only a capital expenditure, but it also is a vital component in the company’s overall process. When air power is down, the entire factory usually is, as well. Keeping a machine running starts with using the right lubricant and ensuring the lubricant is doing the job it is intended for. A routine oil sampling program is the only safe way to maximize the lubricant drain interval and keep the compressed air system — and processes — up and running to keep the compressed air system running for years to come.