Agile, resilient operations derive from tools that make real-time data visible and useful. See post COVID-19 pandemic advice, including from a manufacturer, Anchor Glass.

Learning Objectives

- Real-time access to operational technology (OT) data enables agile and resilient operations./li>

- Operational resiliency components may differ from the OT and information technology (IT) perspectives; commonality remains ability to adapt to change.

- Digital transformation software includes artificial intelligence (AI), analytics, Industrial Internet of Things (IIoT) and augmented reality.

Real-time access to operational technology (OT) data enables agile and resilient business operations. Successful businesses stay agile and ready for challenges their markets present. Underlying infrastructure helps industrial companies pivot in a new direction to quickly adapt operations. This includes having OT and information technology (IT) leaders think about access to factory data more strategically, the benefits of real time data access across an organization, and removing digital blind spots enable agile, resilient business operations.

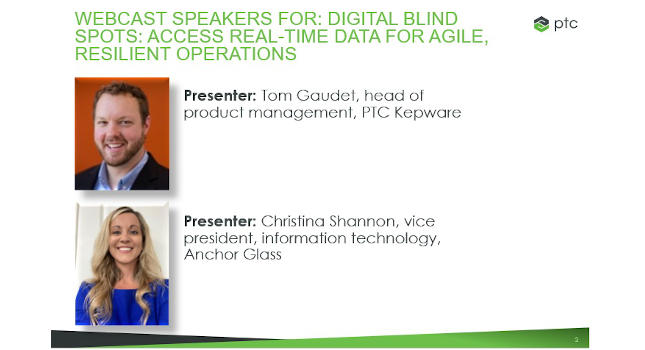

A June 24 webcast “Digital blind spots: Access real-time data for agile, resilient operations” covers these topics, including insights from Anchor Glass about what and how technologies help product quality and expertly customized products.

Operational resiliency may be defined differently from OT and IT perspectives, but at the core of each remains the ability to excel during change. A poll in the webcast will ask participants to choose from a list the top three challenges their organizations face during the pandemic response. Webcast speakers expect to address related issues.

Operational resiliency components

Tom Gaudet, head of product management, PTC Kepware, suggested operational resiliency is “The capacity of an organization to adapt when external conditions pressure operations’ ability to deliver products or services. Such pressures include unsafe, hazardous or compromising conditions that threaten its very existence.”

Christina Shannon, vice president, information technology, Anchor Glass, suggested operational resiliency includes “Initiatives that expand business continuity management programs to focus on the impacts, connected risk appetite and tolerance levels for disruption of product or service delivery to internal and external stakeholders (such as employees, customers, citizens and partners).”

Gaudet and Shannon will look at organizational traits and priorities before, during, and as we emerge from the COVID-19 pandemic.

Topics are expected to include understanding the challenges of connectivity and digital blind spots and the impact it has on operational resiliency, IT/OT convergence, benefits of IT and OT working together, and Anchor Glass use cases.

Tools for digital transformation

PTC specializes in digital transformation and innovation in manufacturing and industrial environments.

By taking an impact-centric approach, digital transformation software allows users to see enterprise-wide value. Digital transformation software includes artificial intelligence (AI), analytics, Industrial Internet of Things (IIoT) and augmented reality. Recognition from Control Engineering subscribers include multiple Engineers’ Choice awards for IIoT connectivity software.

Edited by Mark T. Hoske, content manager, Control Engineering, CFE Media, [email protected].

KEYWORDS: Industry 4.0, IIoT, digitalization, operational resiliency

CONSIDER THIS

What tools and processes are you implementing to increase operation resiliency?