Understand more about alternating current motor specifications and calculations when using the motor with a variable frequency drive.

Learning objectives

- Understand how the information on the motor nameplate details overall motor capabilities.

- Learn how applied speed affects alternating current motor torque producing capability.

- Know how not applying the motor’s rated voltage affects the motors’ performance.

VFD insights

- Using a variable frequency drive (VFD) allows precise control of alternating current (ac) induction motor speed and torque, optimizing performance and energy efficiency across a wide range of industrial applications.

- Selecting the right motor and understanding its torque requirements are essential before choosing a VFD, which can also help regulate voltage and maintain motor health, especially in environments with fluctuating power supplies.

The benefit of using a variable frequency drive (VFD) is the ability to control an alternating current (ac) induction motor in a very specific way that will benefit various applications. Those benefits can be in energy savings, precise operation or operating the motor over a wide variety of speeds.

The relationship between the VFD and the motor begins before the VFD has even been selected. As a matter of fact, you can’t select the drive before you know what motor will be used on the application.

The ac motors come in various designs from the bread-and-butter Design B, four-pole, totally enclosed fan-cooled induction motors to the more recent permanent magnet and synchronous reluctance designs. Selecting the right motor for the job includes many considerations like the installation environment and available power.

The most important aspect is to know how much torque is required to rotate the motor shaft and move the application at the speeds needed. A mechanical engineer should do the math to figure out the “force at a radius” values. An article about motor calculations typically contains formulas for figuring out torque requirements for differing loads; this article doesn’t cover that detail.

Plant and industrial manufacturing experts should consider these five things to select or use an induction motor wisely:

- Using the motor nameplate

- Easy way to figure out a motor’s capability

- V/f curves for induction motors when using VFDs

- Constant torque and constant horsepower ranges

- Accurate voltage when not using a VFD

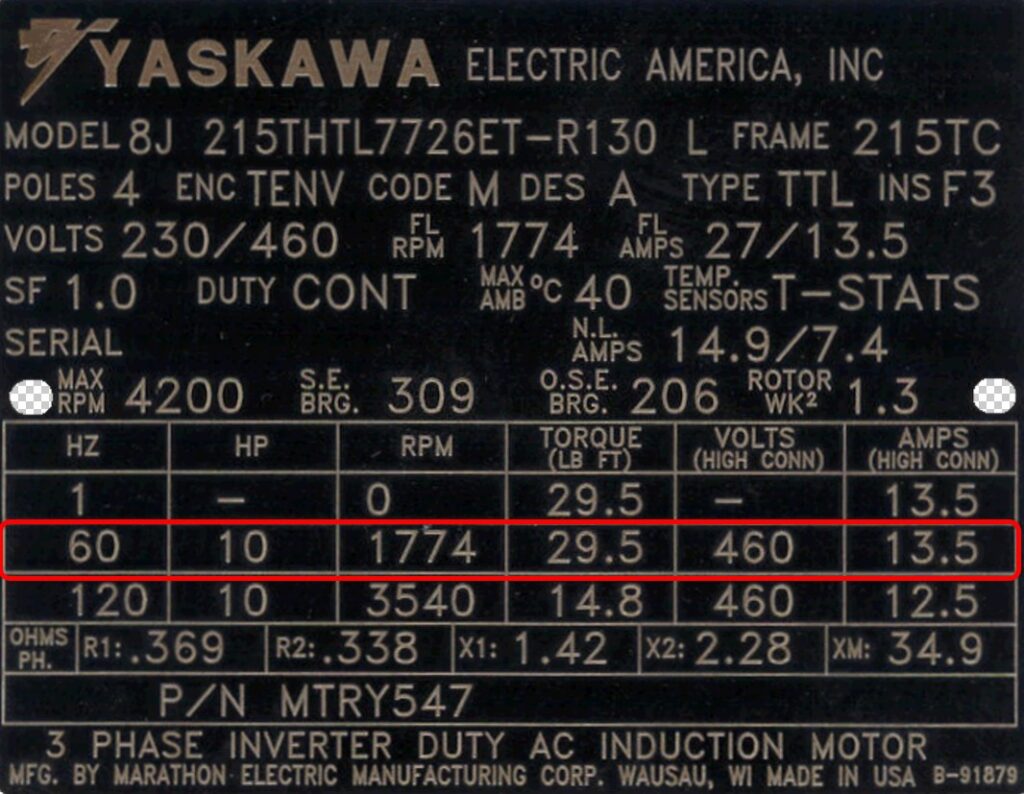

There is a simple way to get a pretty good estimate of the torque an induction motor can produce in foot-pounds. All we must know is the motor horsepower and the number of poles. For a four-pole motor, we can expect 3 foot-pounds per horsepower (hp). A 10 hp ac motor with a rated speed of around 1,774 revolutions per minute (rpm) should produce about 30 foot-pounds We can check our estimate by looking at a motor nameplate (see Figure 1).

The nameplate shows that if you supply the motor with 460 volts ac (Vac) at 60 hertz it will draw 13.5 amps and run no slower (slip) than 1,774 rpm while producing up to 29.5 foot-pounds. It seems our motor torque estimate is fairly accurate (0.5 foot-pounds off). The estimate works just as well for six-pole (4.5 foot-pounds per hp) and two-pole (1.5 foot-pounds per hp) motors as well.

How a VFD can affect speed

Another consideration about using a motor is speed range. Motors have safe operating speeds that align with the mechanical components like bearings and what they can withstand as far as revolutions per minute.

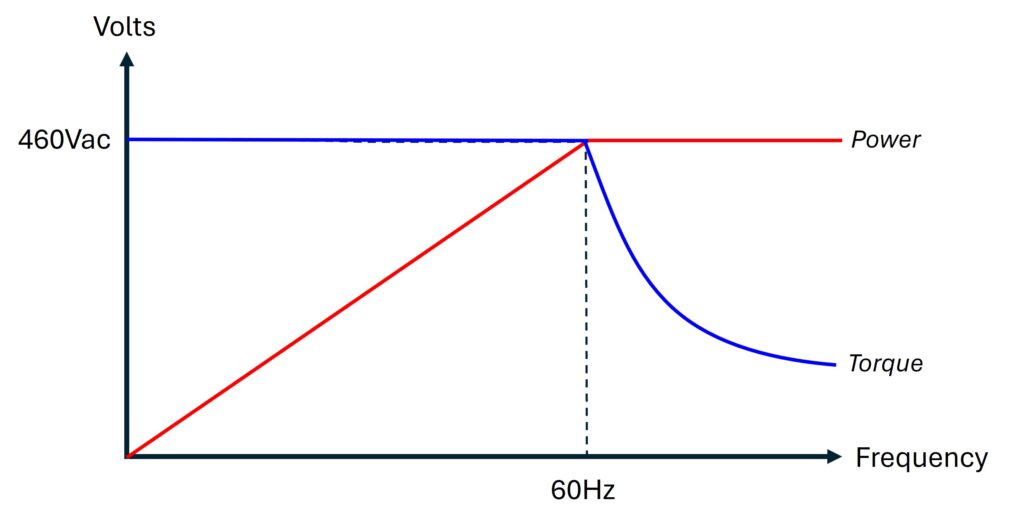

A different speed range to consider is the range of speeds at which the motor can produce its rated torque at when used with a VFD. A VFD can change both the voltage and the frequency that the motor will receive. The ability to produce constant torque at any speed up to the frequency rating of the motor is not based on just the voltage being sent from the VFD to the motor. Rather, the ability stems from keeping an optimal volts per hertz (V/f ) ratio.

The volts per hertz ratio helps determine the magnetic flux density inside the motor. If the volts per hertz ratio is too low, then the density isn’t sufficient to produce the motor’s rated torque. Conversely, if the ratio is too high (too much voltage), the fields become saturated, but torque doesn’t increase. If anything, the motor may become less efficient and overheat. Look at both the motor power and the motor torque versus frequency when the motor is driven by a VFD (see Figure 2). The graphic is a visual representation of the formula:

hp=(T*N)/5,250

It’s a simple enough equation to represent that horsepower is a product of torque (foot-pounds) times speed (rpm) over a constant. It is very common to reconfigure the equation to solve for torque as a product of horsepower times a constant over the shaft speed.

T=(hp*5,250)/N

The first formula explains why the power climbs as the frequency increases (N) and saturates when the motor reaches its rated frequency (60 Hz). The second formula explains why after the horsepower becomes constant, the torque must drop off at one over the speed (1/f, if you prefer). This is referred to as the constant horsepower range or sometimes even the field weakening range.

How VFDs can help torque

If you know what a volts per hertz pattern is in a VFD, you can understand how VFDs will keep a constant V/f ratio (around 7.5 to 1 for a 460-volt motor) to optimize torque. Once the VFD runs out of line voltage, but the frequency continues to increase, the motor is forced to lose torque capability because the magnetic flux field is weakening.

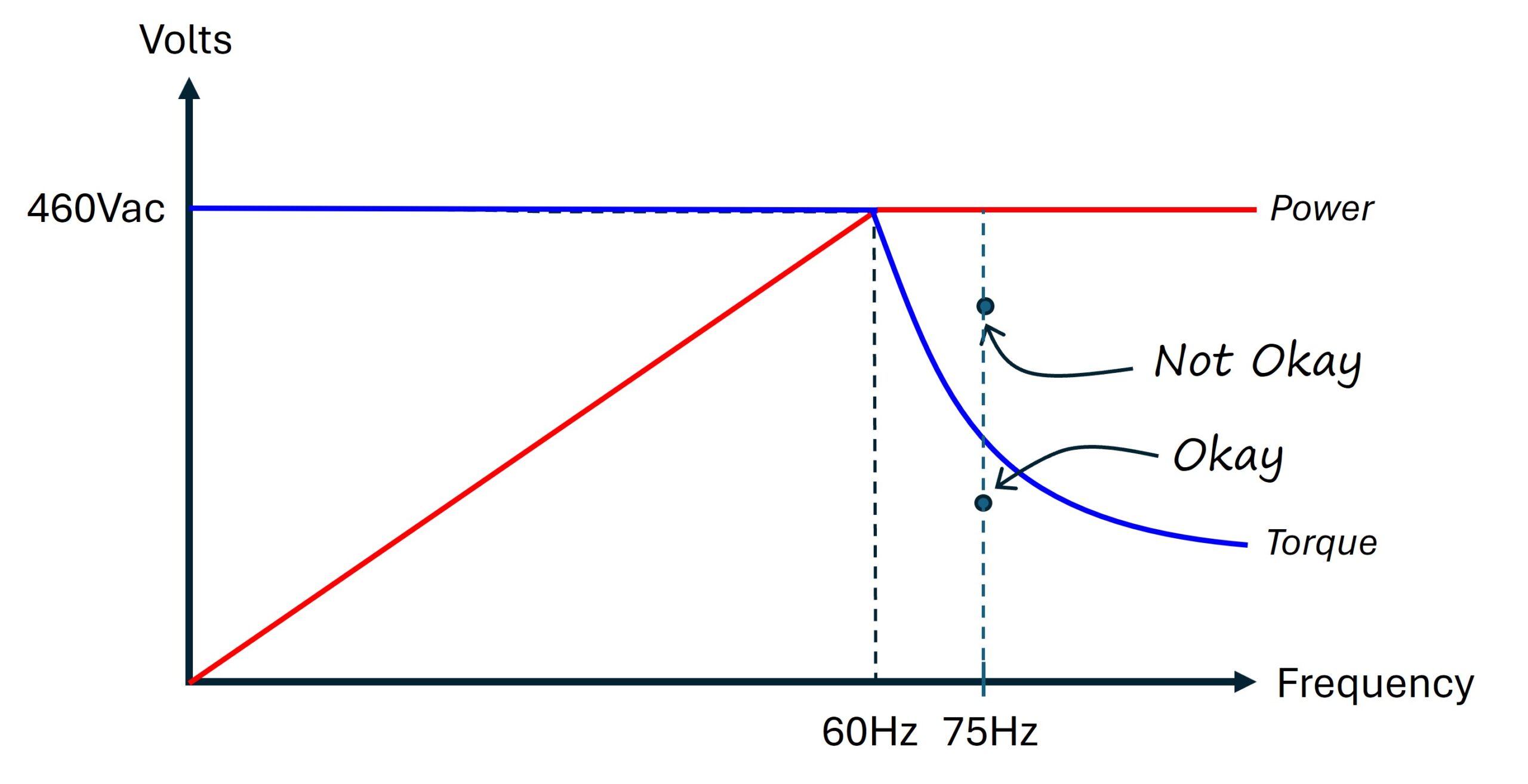

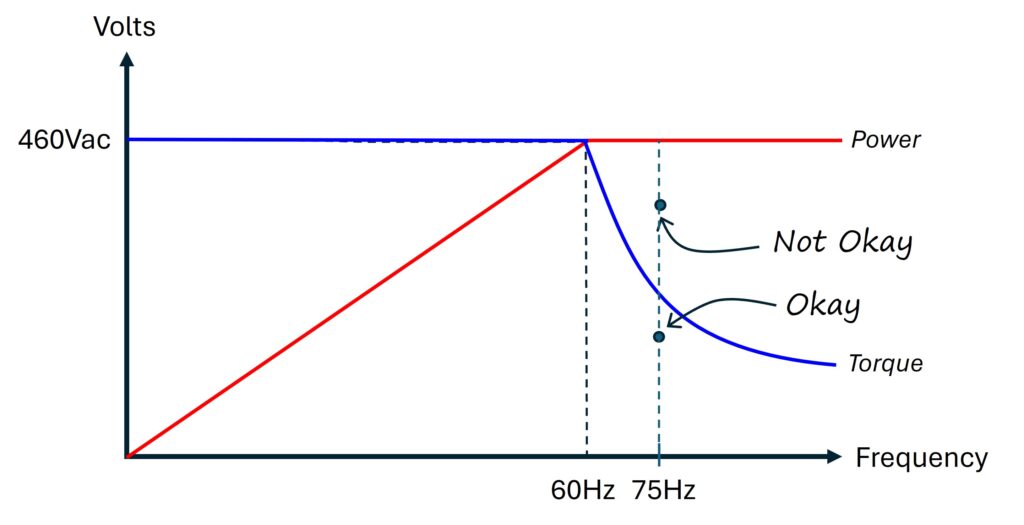

If the user plans to run an application over the motor’s rated frequency, it is prudent to figure out what torque will be necessary at their maximum speed. For instance, if the fan wall needs to run at 75 Hz to create the necessary air flow but the motor’s rated frequency is 60 Hz, a user will need to know what the necessary torque requirements are at 75Hz before you make any motor or VFD selections (see Figure 3).

We can at least ballpark the new larger motor drive combo by going back to the first formula.

We can solve for horsepower by using what torque in foot-pounds we require while at a higher rpm. We can approximate the new rpm at 75 Hz to be about 2,218 rpm. We can use our 29.5 foot-pounds we saw on the earlier motor nameplate as our desired torque.

hp=(29.5*2,218)/5,250=12.5 hp

Unfortunately, manufacturers do not make 12.5 hp motors, so a 15-hp motor and its matching VFD would be used. The system can achieve the torque needed at the speeds necessary to run.

Avoiding failures by using VFDs

Stepping back from VFD usage, examine what happens to motors when they are not run by VFD and are not getting their nameplate-rated voltage. As mentioned earlier, the information on the motor nameplate is very particular. All of the values are dependent on the motor getting the power it was designed for. The manufacturer makes no guarantees about how the motor will perform if any of the values are not at the rating, particularly voltage.

Most industrial motors in the U.S are rated at 230 or 460 Vac (or dual-wound 230/460). The actual average line supply voltages tend to be 240 or 480 Vac across the country. And some areas will actually have their 480 volt supplies run even higher than that depending on how much local load there is and how far from the substation they are.

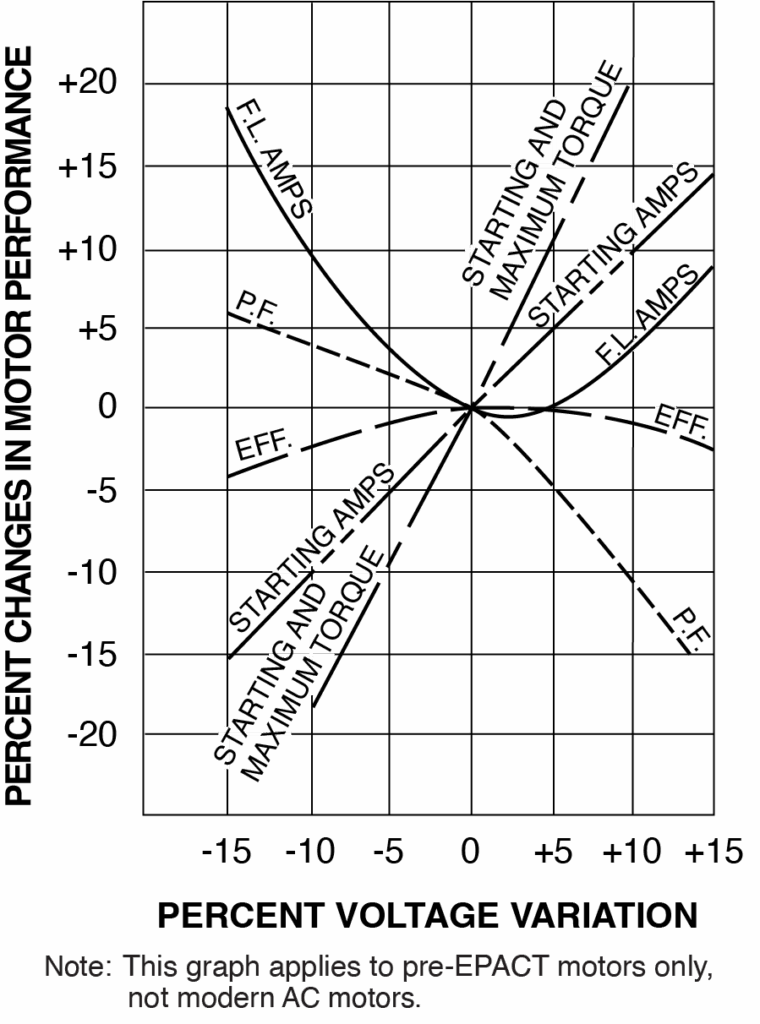

According to ANSI C84.1-2020: Electric Power Systems and Equipment – Voltage Ratings (60 Hz), -5% to +5% variation is allowed on 480 Vac. That puts the voltage potentially up around 504 Vac. So, what happens when you apply 500 Vac to a motor designed for 460 Vac? EASA supplies details to predict graphically what will happen to the motor performance based on voltage variation (see Figure 4).

Mathematically, if we feed that 460 V motor 500 V, we are at nearly 109% of the motors rated voltage. According to Figure 4, at +9% we will gain extra motor torque but at the expense of nearly 5% increase in full load amps and almost 10% increase in starting amps. This will affect the sizing of starters, overloads and cabling. Motor heating will increase and premature motor failure is likely as well.

There are ways to deal with high voltages like transformers and line reactors. Possibly the best way to deal with high voltages is to use a VFD. VFDs are manufactured to deal with 480 Vac plus 10% without failure. The voltage that is passed to the motor is not pinned to the voltage at the drive input but based on the VFD’s programming, i.e., the V/Hz pattern we mentioned earlier. The VFD can give the motor exactly what it was rated for.