With access to rich streams of asset data, how can organizations turn data into action to better predict –– and prevent –– problems before they arise?

Maintenance insights

- Asset performance management (APM) analyzes data in real time to determine asset performance.

- Condition monitoring (CM) can help an operation determine which equipment is headed for failure.

- Reliability-centered monitoring (RCM) targets an organization’s most critical assets.

Industries are shifting how they connect, gather and analyze data. Key trends driving this change include the wider availability of machine learning (ML), increased access to edge computing and the rapid growth of connected devices and sensors.

Manufacturers no longer need dedicated data science teams to gain insights into their operations. Companies have the tools they need — but many still struggle to turn that data into action. One common gap is the continued reliance on reactive maintenance instead of more predictive strategies.

The benefits of a proactive approach are well-documented. For instance, research from the U.S. Department of Energy suggests that implementing preventive maintenance can reduce energy consumption by up to 12%.

Using asset performance management for predictive maintenance

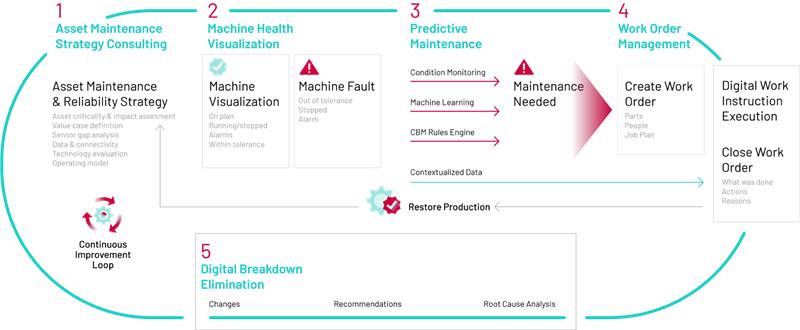

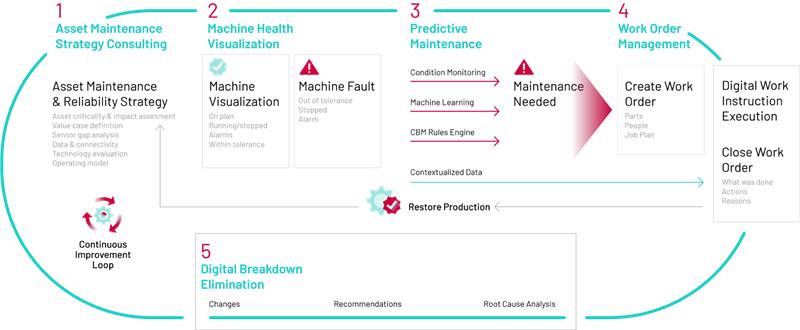

Asset performance management (APM) brings together capabilities like data capture, integration, visualization and analytics to improve asset reliability and availability.

Within APM, predictive maintenance (PdM) uses ML and artificial intelligence (AI) to anticipate equipment issues before they cause downtime. PdM typically includes:

- Condition-based monitoring

- Operations management

- Reliability-centered maintenance

By analyzing condition-based data in real time, PdM provides a clearer picture of asset performance. This enables more informed maintenance decisions, combining engineering principles with advanced data techniques.

Establishing a foundation for modern PdM

Effective maintenance starts with mastering the basics: planning, scheduling and execution. These core elements form the backbone of any advanced maintenance approach.

For a deeper look into PdM, consider the following key areas.

Condition monitoring (CM): Early equipment warnings

How can maintenance teams tell when assets are heading toward failure?

Advanced sensors, edge processing and ML can detect early signs of mechanical or performance degradation. These technologies provide real-time data that helps maintenance teams spot potential issues early and act.

CM isn’t a new concept; it’s been used for decades to establish maintenance routines based on asset conditions rather than time intervals. When integrated into broader maintenance systems, it allows teams to generate maintenance requests well before failures occur, improving both responsiveness and efficiency.

One of the key benefits of CM is the extended lead time it provides. This allows organizations to plan maintenance activities without disrupting production schedules.

Operations management: Turning data into decisions

How do the right people receive the right information at the right time?

Modern operations management relies on data flowing from devices at the edge to platforms that process and visualize information in real time. This layer adds context and clarity, helping organizations act decisively based on what’s happening across their facilities.

It’s not enough to simply detect a problem. Success depends on the ability to coordinate resources, equip personnel and align maintenance tasks with production priorities. Technologies in this space make it easier to manage these logistics and connect insights to operational action.

Reliability-centered maintenance (RCM): Focusing on what matters most

Where should maintenance efforts be prioritized?

RCM helps organizations develop strategies that target their most critical assets. This approach focuses attention on systems that affect safety, production output or compliance, making sure that limited resources are used where they will have the greatest impact.

Consulting and support services in this area help companies align maintenance strategies with business goals. By identifying high-risk areas and performance bottlenecks, RCM helps establish an investment in PdM that delivers meaningful results.

Organizations implementing PdM have seen:

- 10% to 30% improvement in asset availability

- 10% to 15% increases in plant productivity

- Up to 40% reductions in total cost of ownership

- Significant improvements in workplace safety

- Scalable value through integrated data strategies

How certain industries are implementing PdM strategies

PdM is a key priority for global manufacturers in addressing common critical challenges across a variety of industries.

Results from PdM vary based on an organization’s processes, assets and production goals. Many sectors — such as consumer goods, energy, mining and aerospace — have begun adopting predictive strategies but maturity levels vary.

Industries managing remote assets often have strong maintenance systems but still lack full connectivity. These environments present an opportunity to better leverage sensor data with ML models.

Here are some examples:

Process bottlenecks

In discrete and hybrid production sectors like tires, semiconductors and automotive, anomaly detection prevents downtime in critical processes, increasing throughput.

Remote operations: In process industries and original equipment manufacturer sectors where breakdowns can trigger costly delays, predictive models anticipate failures and optimize field service routes, making sure critical assets are prioritized and reducing the likelihood of downtime.

Complex manufacturing processes: In industries where standard condition monitoring methods like vibration analysis are insufficient, deploying complementary systems such as machine vision and robotic inspection helps detect deviations, minimize downtime and maintain product quality.

Safety-critical components: In safety-focused sectors like mining, PdM ensures the reliability of crucial assets like ventilation systems to protect workers.

Environmental control: In sectors like pharmaceuticals, environmental control is crucial. A failure in heating, ventilation and air conditioning or cooling systems could result in scrapped batches or production delays, making PdM especially valuable.

Why PdM matters now

Maintenance departments are the backbone of industrial operations, making sure machinery and equipment run smoothly. However, their capabilities differ, and their effectiveness varies widely. Some companies face challenges in staffing and training, leading to gaps in expertise and efficiency. Others struggle with the sheer volume of data collected, lacking the tools to analyze and act on this information effectively.

Thanks to advances in edge computing and AI, organizations now can build intelligence directly into devices. Edge computing allows data processing to occur closer to the source, reducing latency and enabling real-time decision-making. AI enhances this by providing sophisticated algorithms that can predict failures before they happen, optimize maintenance schedules and even automate responses to detected issues. These innovations enable smarter, more autonomous monitoring and response — marking a new era in maintenance strategy.

Unlocking the future of CM

The future of CM lies in combining hardware, software and services into integrated systems that not only detect problems but help prevent them altogether. Integrating intelligence directly into devices means that equipment can monitor its own health and performance autonomously. This shift toward smarter monitoring reduces the reliance on human intervention, minimizes errors and reinforces timely and precise maintenance actions. The result is a more resilient and efficient operation. Advanced sensors, edge computing and AI work together to provide a comprehensive view of equipment health, enabling proactive maintenance strategies that can significantly reduce downtime and extend the lifespan of assets.

The importance of PdM cannot be overstated. As industrial operations become more complex and data-driven, the ability to predict and prevent equipment failures is crucial. Advances in edge computing and AI are making this possible, ushering in a new era of smarter, more autonomous maintenance strategies. By embracing these technologies, companies can transform their maintenance departments from reactive to proactive, ensuring smoother operations and greater overall efficiency.