Although wireless is heralded as the next big thing in automation and the production operations world, it certainly isn’t brand new.

Although wireless is heralded as the next big thing in automation and the production operations world, it certainly isn’t brand new. The desire to use wireless technology to reduce costs and improve efficiency has been underway for some time in manufacturing organizations supporting applications ranging from materials handling to SCADA systems, from individual machine communications to oilfield microwave communications.

What has changed is the significant emergence of a new generation of products, applications and standards to address the specific challenges for using wireless in large manufacturing facilities. Wireless technologies have enabled greater monitoring capabilities and points of measurement; enhanced workforce mobility; improved safety and security; driven more efficient use of assets, raw materials and energy; and have lowered the costs of plant and process network communications.

Choosing the right wireless technology for the future

As the list of wireless applications grows, so does the list of wireless devices and systems that support these applications. This rapid application growth adds complexity from using multiple wireless technologies to address each application’s specific requirements for coverage, latency and throughput. There is simply not a “one-size-fits-all” wireless networking technology that adequately supports the diverse requirements of industrial applications.

So here’s the key challenge — and the critical choice. Every plant has an extremely important but invisible asset: airwaves — the radio-frequency spectrum that is available in and around your facility. Imagine two or three years from now when you have thousands of wireless devices in your plant from dozens of vendors. As with your wired control networks today, without the right tools for managing the secure, effective coexistence of your airwaves, the wireless communications networks will become slow, unreliable — and unmanageable. The choices you make today will limit your options in managing your future as new wireless technologies become available.

Industrial plants have three basic choices to make when it comes to wireless:

Choice #1: Pick one vendor for everything — You can install proprietary wireless products with everything from one vendor. Choosing all of your wireless networking applications from a single vendor gives you the advantage of an engineered system that is designed to integrate various wireless technologies into a single seamless system.

But as new applications emerge and wireless technologies evolve, your dependence on that single vendor will limit your options and lock you into the capabilities of a single vendor. A critical issue here is whether the single vendor is truly open and standards based. If they claim to be fully open and standards based, but are really not, then the plants’ options can be greatly restricted.

Choice #2: Single-purpose point solutions — You can continue with the point solutions route, which will solve one application problem at a time. The second option is to choose the best or lowest cost wireless technology for one specific application. This approach will have a good chance of delivering the performance and reliability for that one very specific solution.

But there will be no re-use of a common infrastructure. Each low-cost point solution you deploy will demand its own wireless infrastructure, network management and security approach. This approach will eventually create “islands of wireless” which will make it difficult to establish a positive return on your investment for any single wireless technology or application.

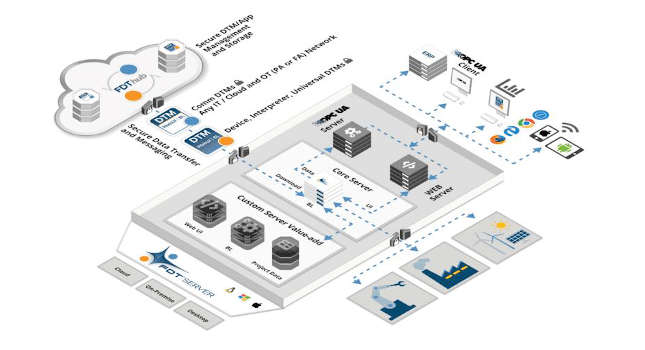

Choice #3: The new generation — Or finally, you can choose to implement an open, standards-based, wireless network that is secure, reliable, rugged and scalable. This truly open wireless infrastructure will allow you to choose exactly the right wireless device and application for your plant with “plug and play” interoperability. Because there is no single wireless network technology, application or vendor capable of delivering the full range of industrial wireless products and applications, an open, shared, wireless infrastructure delivers a greater degree of application flexibility and cost certainty. This approach creates a network of systems based on open standards, best practices and vendor neutrality across all your wireless applications.

The choice should be easy. The financial and operations benefits of industrial wireless are most effectively realized with Choice #3. This provides an open, “future-proofed” solution architecture capable of using the best technologies and applications available — from any vendor — now and in the future. By using the best tools for the job and an open wireless infrastructure, you will avoid the limitations of a single vendor solution and the constraints imposed by numerous point solution wireless applications. Instead, you will enjoy all the benefits of industrial strength wireless in all areas of plant operations for many years to come.

Author Information

Mike Bradley is CEO of