Virtual machines are computers running on software designed to imitate physical hardware.

Technology is constantly changing and computers are more powerful than ever. People can access just about anything in the world on phones, soon even wrists. Virtual machine consolidate multiple physical computers into one and swap data between computers with no downtime.

In the manufacturing world computer hardware has overcome the requirements of most software packages. This means when a company needs to buy a new computer, instead of running it to the max like 3 or 4 years ago, it needs only 10 to 20% of the hardware’s capacity.

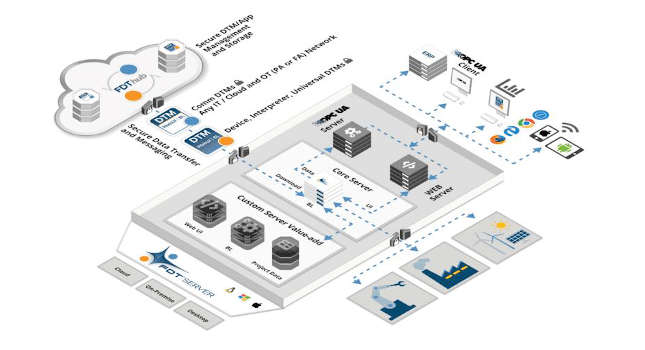

Companies like Microsoft have developed a way to utilize the unused resources using virtual machines. Virtual Machines are computers running on software designed to imitate physical hardware. In the same way a PC can run multiple programs at one time, with virtual machines, multiple computers can run on one PC at the same time.

Virtual machines can:

- Utilize more hardware’s resources

- Consolidate multiple physical computers into one

- Swap between computers with no downtime

- Decrease IT overhead

When a company needs to set up a new machine, they call IT, requisition the hardware, and let them spend a day or two installing all of the software needed. With a virtual machine, a company can get a new computer up and running by simply copying a file and opening it.

Virtual machines are useful when:

- Having an old computer for only one piece of equipment.

- Needing multiple versions of software that don’t play well together.

- Needing to test a new software version without breaking the system.

Leveraging virtual machines to coordinate different PLCs throughout the plant, different HMI systems, or some specialty software for calibrating instruments. Different customers have different systems and they sometimes need to be supported at a moment’s notice. Staying up to date with the latest releases is critical, and dealing with different versions of software without breaking existing installations can be a nightmare. Virtual machines eliminate these problems.

– Alex Marcy is the president of Corso Systems. This article originally appeared on the Corso Systems blog. Corso Systems is a CFE Media content partner. Edited by Joy Chang, digital project manager, CFE Media, [email protected].