The subject was mobility at Syclo’s annual user-group meeting in Rosemont, IL on June 11. The topics went beyond how plant floor devices were moving, but how manufacturers needed to think about using technology on the plant floor. “Technology needs to be blended within an organization, and within a community” said Rich Padula, founder and CEO of Syclo.

The subject was mobility at Syclo’s annual user-group meeting in Rosemont, IL on June 11. The topics went beyond how plant floor devices were moving, but how manufacturers needed to think about using technology on the plant floor.

“Technology needs to be blended within an organization, and within a community” said Rich Padula, founder and CEO of Syclo. “Mobile applications have evolved from a tactical deployment to a strategic deployment. We used to have single-point solutions.”

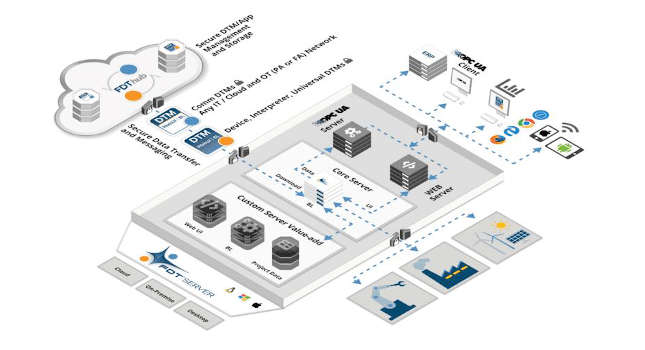

The evolution to what Padula called “device agnostic” technologies is driving more real-time data management regardless of which software provider or which device manufacturer is involved. With standards moving closer and closer to adoption, the industry is now looking ahead to how the data can be used to unclog back-ups in the processing of products and the performance of equipment.

Mobility will help in that effort, by allowing data to be captured at the point of creation, said Marc Chesover, Syclo’s general manager for its UK-based international business. “There’s a lot of excess foot traffic in facilities,” he said. “The value of mobility to management is the value of the ease of moving data and validating data at the point of performance. You need to make sure it’s there in real time, or as close to real time as you can get.

“It’s about the quality, quantity and timeliness of the data,” Chesover added. “It’s no good to make decisions three weeks later. You need to be able to manage your business right there, exactly when it happens.”

One of the great struggles in a tight economy is to find capital funds to drive incremental improvements. The initial cost of technology deployment gives many end users pause. Padula and Chesover stressed the payoff for such adoptions will be found in long-term commitments, not short-term solutions.

“When you start the initial deployment, you’ve got to be thinking about the second, third and fourth deployments,” Chesover told the conference attendees. “Don’t get tied into applications going only to a single back-end device, or only to the devices you use today. You don’t know what’s around the corner.”

Chesover said the initial success of mobility deployment will make other uses readily apparent. “You need to go inside your organization and look at your current mobility deployment and see where you’re finding value,” he said. “A lot of it is done tactically instead of strategically. Look at where else to employ technology to increase value.”