In ac high-potential testing, watch your internal pressure.

A West Texas utility company received an alarm on one of its load tap changers. Field technicians found that one of the vacuum interrupters failed an ac high potential test. The tap changer was disassembled and the vacuum interrupter in question was tested again. Once removed, the vacuum interrupter passed an ac high potential test.

The vacuum interrupter was reinstalled and placed back into service where it again passed an ac high potential test. The following explains why this utility company may have placed a failed vacuum interrupter back into service.

To interrupt high voltages, vacuum interrupters are manufactured with a very low pressure (vacuum) inside. At constant temperature, the internal pressure of the vacuum interrupter is directly proportional to the number of gas molecules inside. Therefore, more molecules inside corresponds to a higher pressure, and fewer molecules correspond to a lower pressure.

When the internal pressure of a vacuum interrupter increases to a certain point, the interrupter will no longer be able to insulate these high voltages. This means that the vacuum interrupter will not pass a high potential test.

If the internal pressure of a vacuum interrupter is just past the point of failing a high potential test, a phenomenon can occur that can temporarily reduce the pressure inside enough to pass the test.

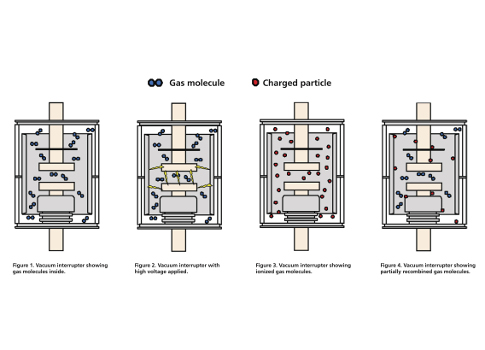

Figure 1 shows a vacuum interrupter with a finite amount of gas molecules inside. Figure 2 shows a high voltage being applied across the open contacts, as in a high potential test. This high voltage breaks down, or ionizes, the gas molecules inside the vacuum interrupter into charged particles, ions, and electrons, seen in Figure 3.

After the high voltage is removed, these charged particles immediately begin recombining into gas molecules. Under certain conditions some of these charged particles may “stick” to the inner surfaces of the vacuum interrupter, which in turn reduces the number of gas molecules inside, shown in Figure 4.

When the number of gas molecules is reduced, the pressure is also reduced. This reduction in pressure is temporary and dependent on a number of factors; however, it can result in a vacuum interrupter’s internal pressure being reduced enough to pass a high potential test. These remaining charged particles will eventually recombine and return the pressure to an unsatisfactory level.

The amount of time it takes for complete recombination varies widely. After this recombination occurs, the vacuum interrupter will, again, not pass a high potential test.

Julia Neves is president of Vacuum Interrupters, Inc.