For original equipment or replacements, package boilers offer efficiency, redundancy, flexibility: Advanced controls manage steam ramp-up and ramp-down for better combustion efficiency and heat transfer; improvements create efficiencies as high as 85%.

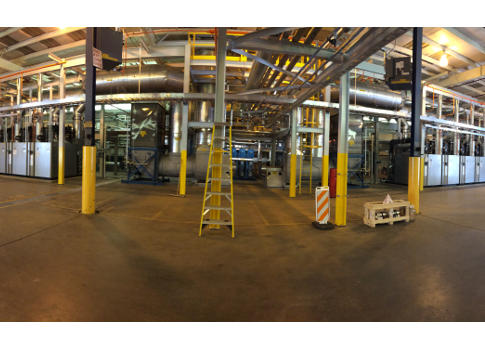

The name "package" tells part of the story. But not everything. Package boilers are meeting the needs of many facilities, both as original equipment and as replacements. Because they are totally factory-assembled, they offer quick installation and startup. They are built under controlled conditions and are tested before shipping. Owners can be confident they will run right from the beginning, and are discovering other advantages to package boilers as well.

Better than ever

Package boilers have been around for a long time. In years past they were often seen only as the solution for small steam users who couldn’t justify a site-built boiler plant. That has changed. Today many larger steam users are selecting package boiler solutions in order to save floor space, add unit redundancy, and maximize plant reliability. Many of today’s package boilers offer efficiencies comparable to built-up plants, at a cost that is very competitive.

A clear trend is emerging toward a modular approach to boiler capacity, using multiple package boilers. Doug McMaster is Vice President, U.S. Operations for Miura America Co. Ltd., a major provider of package boilers. He comments on this trend, "Modularity allows systems to expand or downsize if future needs change. Also, modularity can achieve the redundancy requirements of the facility much less expensively."

Reduce redundant capacity needed

As an example, he cites a plant that needs 1,200 boiler horsepower. If it used a single 1,200 horsepower boiler, it would need a second 1,200 horsepower boiler for emergency backup. "Due to the lengthy startup time for these large boilers, the second boiler would need to be idling (in standby mode) just in case it’s needed. A big waste of energy."

He notes the benefits of alternatively using smaller, modular boilers for this situation. "We could achieve the required horsepower with five 300 horsepower units — four to handle the load and the fifth as a standby unit. This would probably result in a 30-40% reduction in capital investment." Because of the rapid startup capability of most package boilers, the fifth unit would probably not even need to be kept hot.

Faster maintenance

McMaster points out that simplified maintenance is another advantage to the modular system approach. "Modular boilers are typically easier to maintain due to their smaller size. Annual inspections take a half-day rather than the week needed for traditional boilers." And because the maintenance is done on one boiler at a time, there is no required steam outage during the maintenance period.

He adds that modular boilers are safer due to their low water content. "Some 300 horsepower boilers contain as little as 120 gallons of water, versus approximately 2,000 gallons in older fire-tube boilers. The amount of energy stored in large volumes of high temperature/high pressure water and steam is the primary cause of catastrophic failure of older boilers."

Quick to ship and install

A real advantage is their compact size. Most package boilers can be shipped in a closed van and are skid-mounted for rapid installation. Many will fit through the typical double door into a new or remodeled boiler room. Often plant capacity can be increased while reducing the footprint of the system if replacing an older boiler and auxiliaries with package units. Vertical package boilers are especially economical in their use of floor space.

Institutional steam users in particular can benefit from the package boiler solution. They are especially attractive when there is great seasonal variation in the demand for steam or hot water, for example with college campuses, hotels and resorts, and other locations where steam or hot water is used for space heat. Such an owner might install four or more package boilers, with most of the capacity being used in the heating season, and a single unit kept hot during the rest of the year. In this way, equipment maintenance is reduced and the single unit can operate in the efficient part of its range.

Smaller "pony" boiler

Hurst Boiler and Welding Company is another major manufacturer of modular boilers, both horizontal and vertical types. Chad Fletcher from Hurst talks about the role of smaller package boilers in systems such as healthcare centers that have a large single boiler to meet most of the needs during much of the year. He notes that in those situations, it is often advantageous to have a second, smaller package boiler to meet system needs during times of the year when it is not necessary to keep the large boiler hot. "In the summer months, they have no need for space heat, so they do not need the larger boiler." The smaller unit will meet their needs for cooking, water heating and sterilization. He adds, "But it will also allow them to operate, though on a much smaller scale, if the larger boiler goes out."

You might be a candidate for a package boiler if:

- You want to add boiler redundancy for increased reliability

- Your seasonal steam or hot water requirements vary greatly

- You want to have flexibility to add or remove boiler capacity in the future

- Your boiler room doesn’t have space for another standard boiler

- You could benefit from separate steam and hot water boilers

- You don’t want to keep a large backup boiler hot year round

McMaster and Fletcher both point out the importance of installing the correct control system for single or multiple boiler systems. This is one area where there have been great advances in recent decades. For example, Fletcher explains that Hurst offers control systems for all boilers and related equipment, including the capability for remote monitoring and operation from anywhere with internet access. Alternatively, he points out, some boilers are directly controlled through the central building management system.

Improved efficiency designs

Operating efficiencies of package boilers have seen significant increases in recent years. Improved burner designs allow for a more even flame spread and more precise flame impingement on the tubes. Increasingly, package boilers include an on-board stack-mounted economizer, allowing improved heat recovery and high feedwater temperatures. Advanced controls manage steam ramp-up and ramp-down for better combustion efficiency and heat transfer. The result of these improvements means efficiencies as high as 85% are being achieved.

Modern package boilers are also compliant with air emission standards. For example, Miura offers models that meet NOx standards of 9 ppm. According to McMaster, these boilers have also been tested and certified as compliant with the newer NCASI PM2.5 standard. He says, "We believe this stricter regulation will become more widely recognized in the near future."

Package firetubes have advantages

Cleaver Brooks offers a line of package firetube boilers in sizes up to 2,200 HP. Gregg Achtenhagen is the Senior Manager, Package Boiler Systems for Cleaver Brooks. He points out, "Since most institutional users do not need pressures above 250 psi, package firetube boilers can now be used in lieu of industrial watertube boilers." He explains that this approach offers quicker installations, less floor space, higher boiler efficiencies and both standardized and customized control packages to meet user requirements.

Achtenhagen adds, "For institutions that do not use steam at all, or have only minimal use for steam, the trend is to use condensing boilers or flexible water tubes in hydronic installations. The driver is mainly high efficiency — over 92%, depending on operating conditions."

Trends on institutional campuses

Other trends noted by Achtenhagen are skid-mounting of multiple package boilers, decentralization of boiler plants on institutional campuses, and a move to separating steam and hot water production to take advantage of the efficiencies of condensing boilers. He also notes the increasing use of both conventional and condensing economizers in the boiler package.

He points out that with most conventional boilers, efficiencies are reduced 2% to 4% at part load. However, condensing boilers actually have higher efficiencies at part load. He notes that for most boilers, an annual inspection is required by code. On the smaller condensing boilers, only a general inspection of the burner is required. With larger firetube boilers, an annual tuneup is recommended, along with a tube cleaning if the boiler is fired some or all of the time with oil.

Wide number of choices

Every situation is different. What is important is that today there is a wide range of package boiler solutions for both industrial and institutional steam and hot water requirements. In evaluating the possibilities, be aware that systems are more efficient and more compact than ever. More package boilers may be in your future.

MORE INFO:

Clayton Boilers

Cleaver Brooks

Energy Solutions

This article originally appeared in the Gas Technology Summer 2016 issue.