Factory automation increases will drive worldwide growth rate of 75% by 2015

The world market for industrial PCs could reach $3.52 billion by 2015, according to a new report from IMS Research. That would be a 75% increased from the current IPC market of $2.07 billion.

The world IPC market was hit very hard by the global recession. The 2010 IPC market rebounded strongly; with all regions and sectors registering strong growth as projects that had been postponed came back on line and IPC distributors and users replenished stock.

Report author Mark Watson talked with CFE Media about how market factors in manufacturing, specifically factory automation, would impact the overall market going forward:

CFE: The report notes much of the growth in the industrial PC market is in areas outside of factory automation. What is the prospect in this market by itself, especially in the developed markets?

Watson: At a world level the factory automation sector is forecast an annual average growth rate of about 9% to 2015, which is below the rates projected for the sectors mentioned in the release. However, due to the large size of the initial market (almost 50% of total IPC sales revenue in 2010), the factory automation sector will see good revenue growth over the forecast period.

CFE: The growth of automation in emerging markets will mean a growth in industrial PC use. What are some of the barriers to growth in these markets?

Watson: Adoption of competitive solutions such as PLC + operator terminal, embedded computer boards and (rugged) mobile devices may all negatively impact on future IPC revenue growth. At present the economic uncertainty and strict lending mean that some projects cannot get funding, which also will impact automation component markets.

CFE: Is the definition of industrial PC expanding to include new technologies such as tablets and smartphones?

Watson: Within the IPC report we do not include any rugged mobile computers or consumer devices that are used in a harsh environment. We are looking to do a separate piece of research on this market late in 2H12.

CFE: Which area in the industrial PC market seems to get the most attention: information display, data management or integrated control? Which area seems to be driving new equipment or replacement purchases?

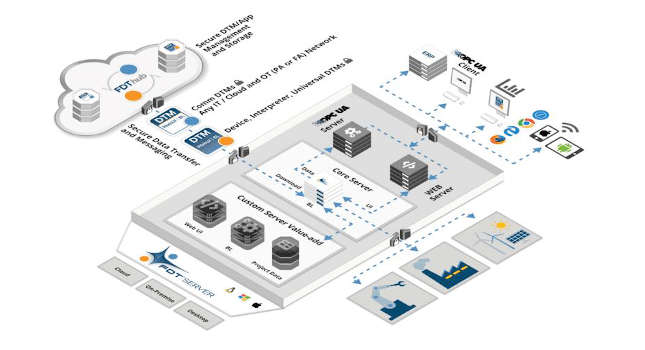

Watson: As system performance increases and relative prices decrease it seems that IPCs are being used for multiple functions and are especially well suited for integrating the factory network with the enterprise network. Data can be easily gathered, analyzed and distributed so that accurate info is available at all levels of the organization. Multi-core processors and hypervisors are being used to run different apps simultaneously. Widescreen displays are also being used to display more data (for multiple apps) at the same time. IPCs are being used more for machine control but the PLC still dominates this application. More likely, going forward, PLCs and IPCs will be used alongside each other.

IMS Research

www.imsresearch.com