OSHA’s new guidance highlights a risk that many still underestimate: serious arc flash hazards can happen at voltages as low as 120 V.

Learning objectives

- Understand OSHA’s updated expectations for arc-rated personal protective equipment (PPE) use at 120/208 volts.

- Know which job roles and environments are affected, including motor control centers and shared electrical spaces.

- Be able to review and revise PPE programs, lockout/tagout (control of hazardous energy) procedures and training to meet current enforcement priorities.

Arc flash insights

- This article walks through what the update says and what safety managers should be checking for regarding their policies, procedures and training.

- Occupational Health and Safety Administration’s new personal protective equipment guide resets the arc flash safety standard.

Can something as common as 120 volts (V) really cause an arc flash serious enough to send someone to the hospital or worse? Surprisingly, yes. And that misunderstanding is one reason Occupational Health and Safety Administration (OSHA) issued a major update in November 2024, its first significant shift on arc flash personal protective equipment (PPE) guidance in nearly 20 years.

The updated guide applies broadly across general industry, commercial facilities and maintenance operations, especially in environments like motor control centers (MCCs), where energized work is frequent and often shared among multiple trades. It reinforces existing requirements under OSHA standards, particularly 1910 Subpart S, while aligning with best practices already outlined in NFPA 70B: Standard for Electrical Equipment Maintenance and NFPA 70E: Standard for Electrical Safety in the Workplace.

Importantly, this guidance does not change the separate rules that govern utility transmission and distribution work under 1910.269 and 1926 Subpart V, though it closely aligns with principles already established in NFPA 70E and 70B. But it does sharpen expectations, most notably around arc-rated PPE use during low-voltage tasks and corrects persistent misunderstandings that have long shaped field practices.

OSHA’s arc flash PPE guidance

For a long time, many teams treated anything less than 240 V as low-risk, almost routine. But OSHA’s 2024 guidance calls that out. It states plainly: even low-voltage tasks can carry serious arc flash hazards. The new emphasis isn’t on the voltage but on exposure.

If someone is working near exposed energized parts, even at 120 V, the risk is real. And that means arc-rated PPE is expected.

Here’s what’s changed or clarified:

- Arc-rated PPE applies to low-voltage work — yes, even 120/208 V — if there’s any exposure to energized components.

- OSHA directly addresses a widespread assumption: that equipment under 240 V “can’t arc.” That idea is no longer acceptable, nor is it safe to assume.

- The focus shifts from voltage to task conditions: available fault current, enclosure type, worker proximity all matter more than the number on a label.

- Environments like MCCs are called out for their high exposure potential, even at common voltages.

Another major point is what qualifies as “de-energized.” OSHA doesn’t leave this vague. If the task doesn’t meet full lockout/tagout (LOTO) or electrically safe work condition (ESWC) requirements, it must be treated as energized, even if the breaker’s off. That’s in line with 29 CFR 1910.147 and 1910.333.

In short: Flipping a switch isn’t the same as verifying zero energy. And assuming otherwise is no longer something OSHA’s going to overlook.

While this isn’t a new regulation, it does tighten the practical expectations under the General Duty Clause and PPE standards (1910.132-138). It fills in the gaps that outdated training or misread standards left behind.

Who this arc flash guidance applies to

This guidance is aimed squarely at general industry, where energized work on low-voltage systems is common and often misunderstood. It addresses the everyday environments where arc flash risks have historically been downplayed: commercial facilities, light industrial plants, maintenance shops and multitrade electrical spaces.

Who’s clearly covered:

- General industry workers involved in electrical installation, diagnostics, maintenance or servicing

- Electricians working in commercial, residential or industrial contexts

- Facilities staff and operators who interact with or near energized panels, disconnects or MCCs

- Shared workspaces where multiple trades work around the same energized equipment

What about utility workers? Workers involved in electric power generation, transmission and distribution are governed by separate OSHA standards, namely, 29 CFR 1910.269 (general industry) and 1926 Subpart V (construction). These rules already contain detailed arc flash protection requirements.

However, here’s where it gets nuanced: Even nonutility employers may have workers who fall under 1910.269 if those employees perform “utility-type work,” such as managing electrical distribution throughout a facility or industrial campus.

So, the distinction isn’t based solely on job title or employer type. It depends on the nature of the work and the hazard exposure involved. If energized electrical exposure is present and the task doesn’t fall under the utility framework, this new guidance will likely apply.

Implications for mechanical, electrical system managers

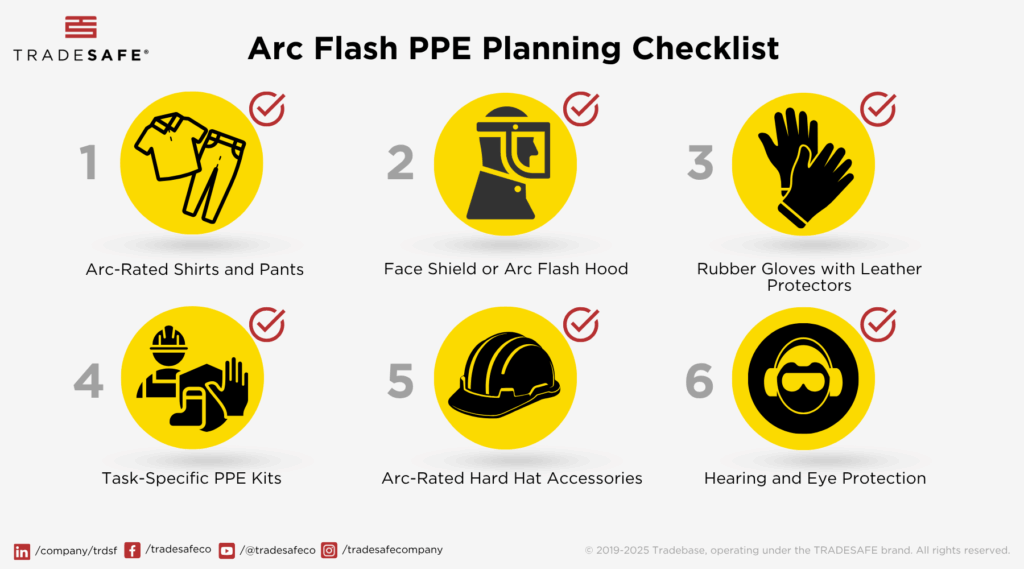

One of the most immediate and visible impacts of the updated guidance is the expectation for expanded PPE use even during tasks many teams still consider routine. That shift brings a very real question to the table: Are your current budgets and inventories aligned with OSHA’s clarified expectations?

The answer, in many cases, is probably not.

Arc-rated PPE, once reserved for high-voltage or utility settings, is now explicitly recommended for lower-voltage energized work. That includes common activities performed at 120/208 V, where energized exposure hasn’t been eliminated through full LOTO.

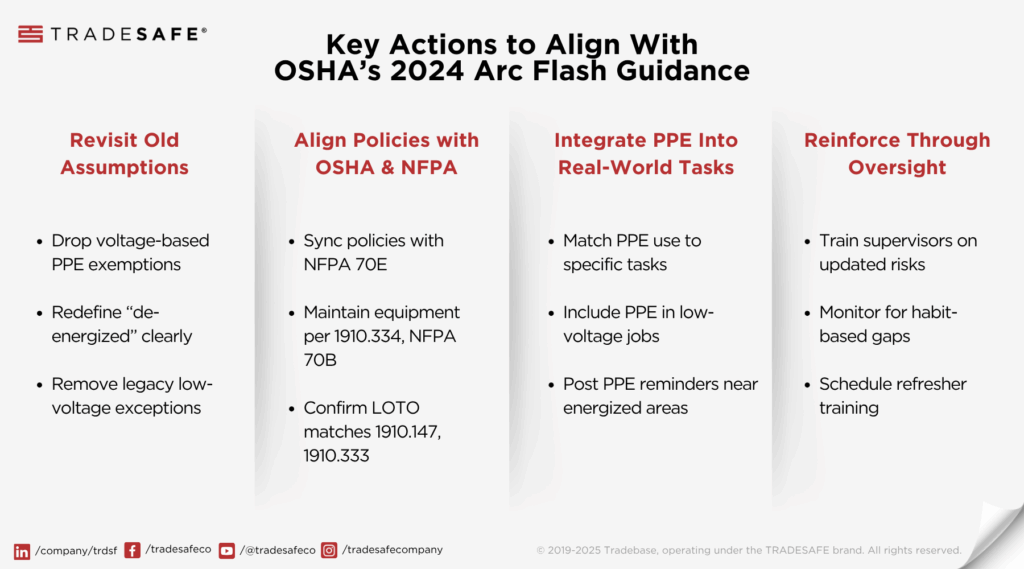

For managers reviewing PPE needs, especially in areas where energized work at lower voltages is routine, it helps to have a clear picture of what’s commonly recommended. Figure 1 highlights several types of gear that many teams are putting in place as part of their arc flash program.

Special attention is warranted in MCCs or other confined energized spaces. These are high-risk zones where arc flash exposure is both more likely and potentially more severe due to the proximity of workers to live parts.

PPE needs to be suited not just to the voltage, but to the task, the equipment condition and the environment. That makes upfront investment in PPE planning and procurement necessary. Treating arc-rated gear as optional for low-voltage work is no longer defensible under OSHA’s current position.

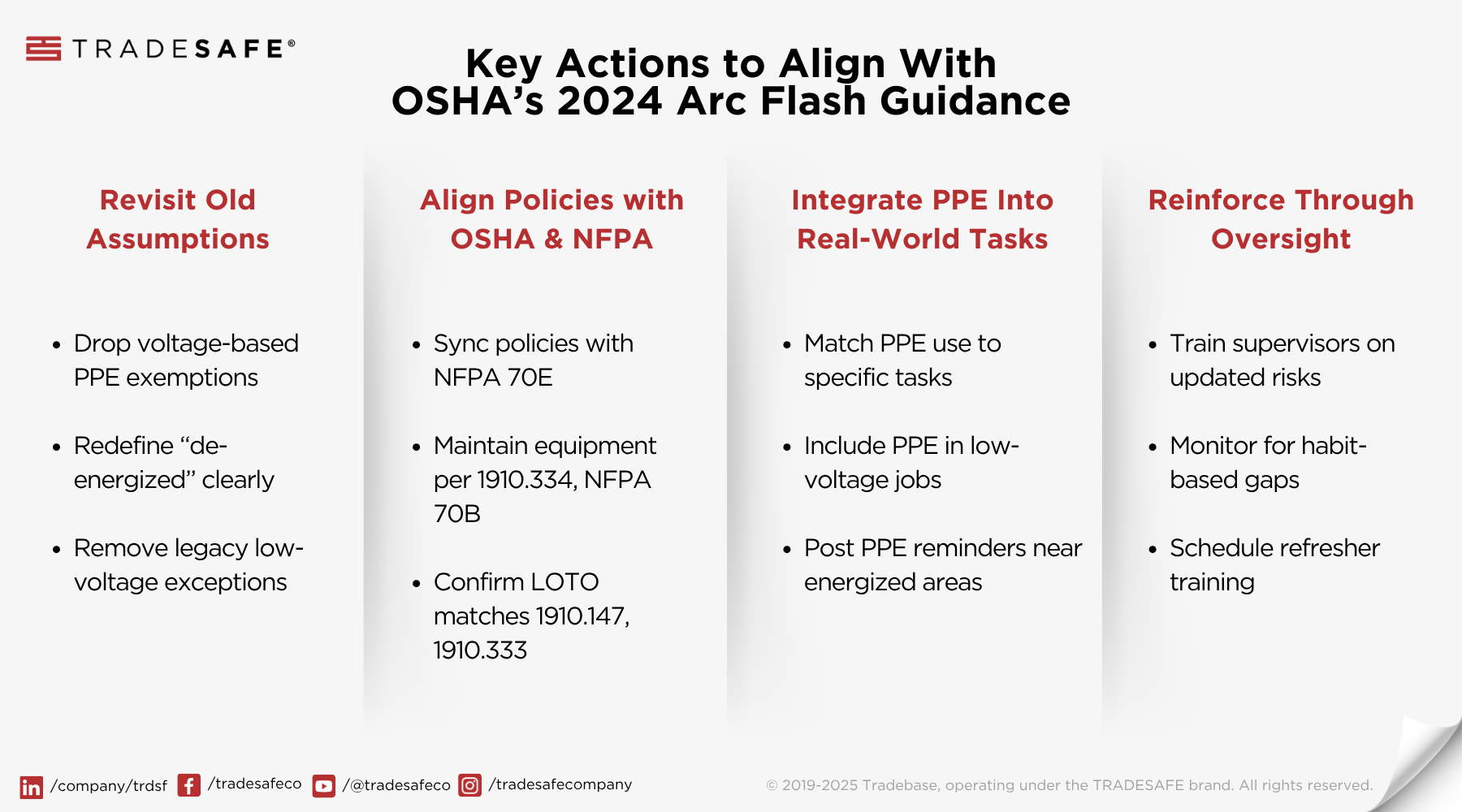

Arc flash safety policy and procedure overhaul

Upgrading PPE is just the start. The bigger challenge and arguably the more consequential one is reworking safety policies that still rely on outdated assumptions. OSHA’s guidance signals that too many programs treat electrical safety as static, when risk conditions shift with every energized task.

To help close the gap, OSHA has made it clear that several common field beliefs no longer hold up under current expectations (see Table 1).

Table 1: Outdated beliefs and correct practice for arc flash

| Outdated belief | Correct practice |

| 120 volts can’t cause arc flash | Arc-rated PPE is required when energized exposure exists, even at low voltages such as 120 V |

| Turned off = de-energized | A system is only de-energized when LOTO and voltage verification are complete |

| Low-voltage work doesn’t need PPE | PPE must match the risk of the task, not the voltage label |

| Quick diagnostics aren’t high-risk | Any task near exposed energized parts requires protection and procedure |

Table 1: Comparison of outdated beliefs versus correct arc flash safety practices. Courtesy: TRADESAFE

Policies must extend beyond assumptions and enforce procedural rigor, especially when energized diagnostics or servicing are involved. For system managers, this means:

- Rewriting procedures to reinforce that the power-off does not equal de-energized.

- Emphasizing LOTO and ESWC protocols at every level of work planning, not just for high-voltage or “high-risk” jobs.

- Eliminating language in policies that downplay the need for PPE below 240 V. Lower voltages can pose the same risks depending on the frequency of the task and exposure to hazards.

- Requiring field verification of de-energization (test for absence of voltage) before work begins.

This also applies during troubleshooting, voltage testing or simple resets, tasks often assumed to be “quick and safe.” If energized exposure hasn’t been eliminated, then PPE and procedural controls are nonnegotiable.

For example, resetting a breaker with an internal fault can trigger an arc flash even at 120 V. If the defect goes unnoticed, the worker still faces hazards. Limited experience or training and a false sense of security about “low-risk” tasks can leave employers unprepared for the consequences.

Training and supervision

Technical policies are only as strong as the training that supports them. And even the best-written procedures won’t hold up if workers fall back on assumptions, especially around what’s energized and what’s not.

OSHA’s 2024 guidance pushes supervisors to step in more actively, not just during onboarding, but during day-to-day work. The goal is to make sure safety practices match the actual risks in front of workers.

To stay aligned with the updated expectations:

- Training should focus on identifying energized exposure, especially during diagnostics or panel work.

- PPE use must be reinforced during routine jobs (no exceptions based on voltage alone).

- Supervisors should monitor how procedures are being followed.

- Retraining should be scheduled, not reactive, based on the frequency of exposure, not incident history.

Supervisors are often the last chance to catch a gap before it turns into an incident. That’s why this part of the program needs just as much attention as equipment checks or PPE budgeting.

Hazard assessment and maintenance coordination

Even though OSHA’s latest guidance doesn’t mandate arc flash risk assessments, it strongly encourages them. The complexity of modern electrical systems means risk can’t be judged by voltage labels alone.

When planning energized work, a formal arc flash study can help determine three things:

- The available incident energy at specific locations.

- The correct arc-rated PPE needed for that exposure.

- Whether existing safety boundaries are adequate.

Without this data, teams are left to guess and guessing leads to either overprotection or under-protection, neither of which builds trust or reliability.

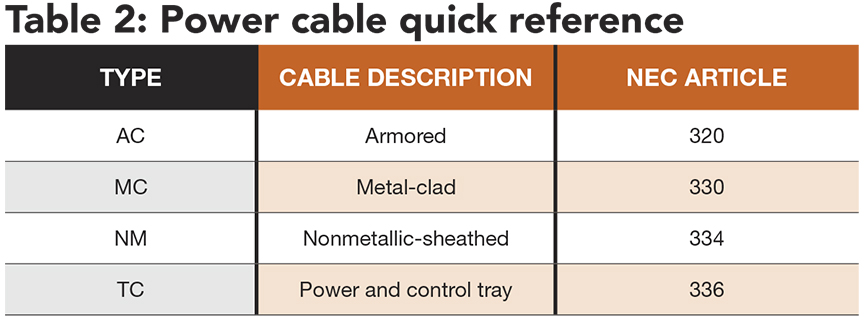

In practice, these decisions are shaped by a range of conditions. There are several common assessment factors connected to protective planning (see Table 2).

Table 2: Assessment factors for protective planning

| What you assess | Why it matters | What it affects |

| Available fault current | Indicates how severe an arc flash could be | Determines minimum PPE rating and boundary size |

| Equipment condition and enclosure type | Poor maintenance increases arc likelihood | Drives cleaning, torque checks and inspections |

| Worker distance and task type | Proximity and energized contact raise risk | Influences safe approach practices and PPE use |

| Labeling accuracy and system updates | Incorrect or outdated info misguides decisions | Triggers relabeling and study recalculation |

Table 2: Table of key assessment factors and their influence on protective-planning decisions. Courtesy: TRADESAFE

But hazard assessment doesn’t stop with calculations. Coordination between electrical and mechanical teams is just as critical, especially during scheduled maintenance or troubleshooting. Tasks overlap, trades mix and the risk increases when one team assumes another has verified safety conditions.

To strengthen your program:

- Coordinate assessments across departments.

- Review existing labeling and ensure it reflects current system configurations.

- Tie hazard assessment results directly into written work procedures and PPE selection.

- Make arc flash studies part of your update cycle after system changes or upgrades.

- Evaluate potential engineering solutions (e.g., panel-mounted devices that indicate voltage presence, current or fault conditions).

Maintenance is also equally important. Equipment that’s neglected can cause unexpected failures and elevate incident energy. OSHA references 1910.334 here: maintaining gear in good condition is one of the best ways to lower the odds of an arc occurring in the first place.

Closing arc flash compliance gaps

With OSHA’s guidance reinforcing expectations around low-voltage arc flash hazards, the next step is verifying. Many facilities already have safety policies in place, but that doesn’t mean they align with what’s now clarified.

OSHA’s 2024 guidance doesn’t change the written standards, but it does change how clearly those standards are being interpreted.

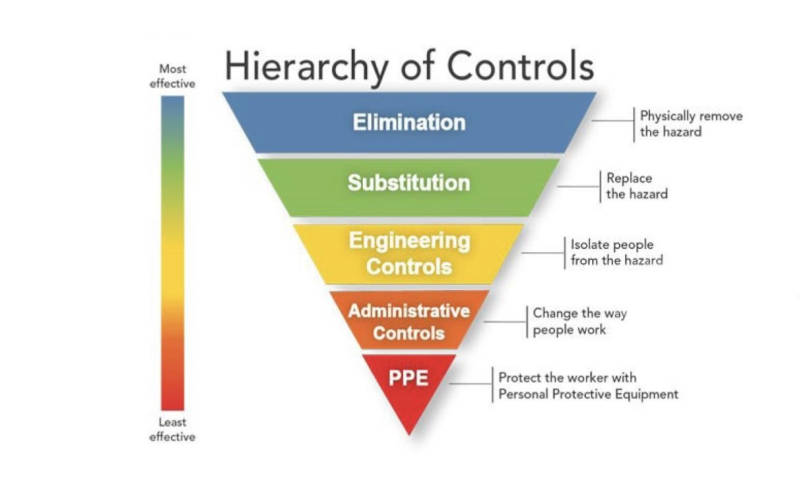

If your team is still using “under 240 V” as a reason to skip arc-rated PPE or shortcut lockout procedures, this is your warning light. The guide reinforces what was already in place: if there’s energized exposure, it needs to be treated like any other hazard (even at low voltage), with engineering, administrative and PPE controls evaluated in the hazard assessment.

Here’s what matters:

- Workers can still become injured, burned and experience life altering injuries, even when working with only 120 V.

- OSHA can still issue citations using the General Duty Clause if a known hazard isn’t addressed.

- PPE expectations in 1910.132-138 still apply even if the voltage is low.

- The moment energized work happens without full LOTO or an ESWC, compliance depends on PPE and procedure.

Plant managers and safety experts don’t need to rewrite your safety manual from scratch. But facilities do need to make sure what’s written matches what’s happening in the field, especially in MCCs, control panels or anywhere energized work is routine.

If the risk is real and the controls are known, OSHA expects teams to act accordingly.