Though manufacturing is a significant contributor to greenhouses gases globally, companies can take steps toward energy efficiency and sustainability.

Energy management insights

- U.S. manufacturing contributes to about 23% of global carbon emissions.

- Analyzing data is a significant step toward implementing sustainability practices in industrial settings.

- Integrating energy management and production processes drives operational efficiency and sustainability.

Manufacturing has a big carbon footprint. It’s responsible for a significant chunk of global greenhouse gas emissions, with U.S. manufacturing contributing to about 23% of global carbon emissions, according to the Environmental Protection Agency.

And while many companies want to be greener, the pressure to meet immediate customer and business demands often means sustainability takes a back seat. But that’s changing fast. Sustainability is imperative for cutting costs and producing more with less. Digital transformation became the bridge that enables a significant return on investment (ROI) in sustainability, by unlocking a huge potential to optimize energy and the use of raw materials using data and artificial intelligence (AI).

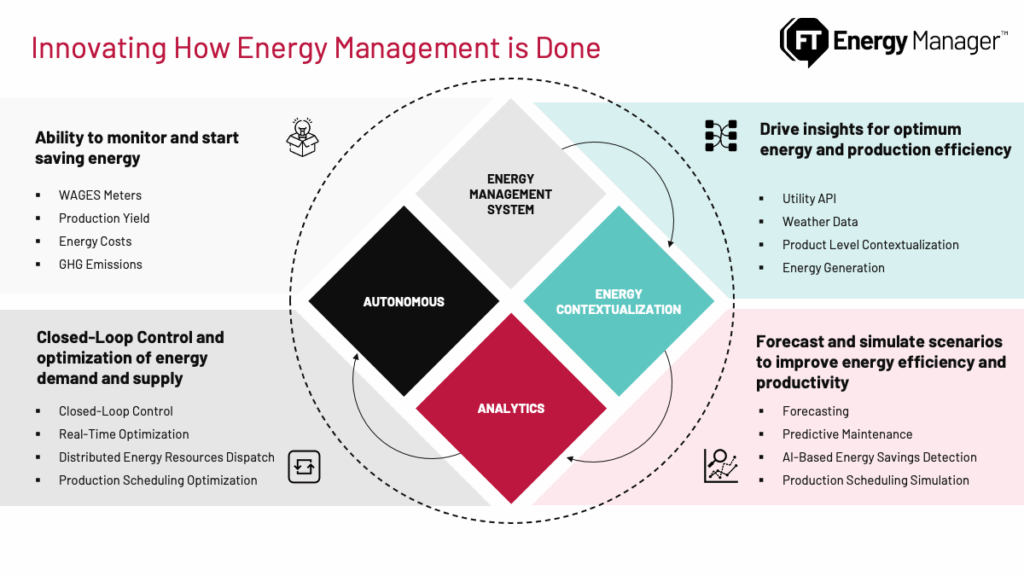

Implementing digital technologies for energy management has historically been a cumbersome journey for organizations due to the complexities involved when considering the dependencies of connecting and installing energy meters across production facilities, ensuring that the meters are linked to a network infrastructure and setting up the minimum requirements to gather data. Also, applying analytics and AI to optimize energy efficiency may seem like a distant goal for many as establishing the foundation for connecting meters’ data thoroughly across a plant can take a long time.

By leveraging agile methodologies and data science expertise, companies can develop an approach to streamline energy management and drive faster value and scalability.

Organizations should consider an agile approach that considers the context of energy, production and quality data together. By using data science tools that integrate, disparate datasets can drive faster value and scalability.

Starting the energy management journey with data

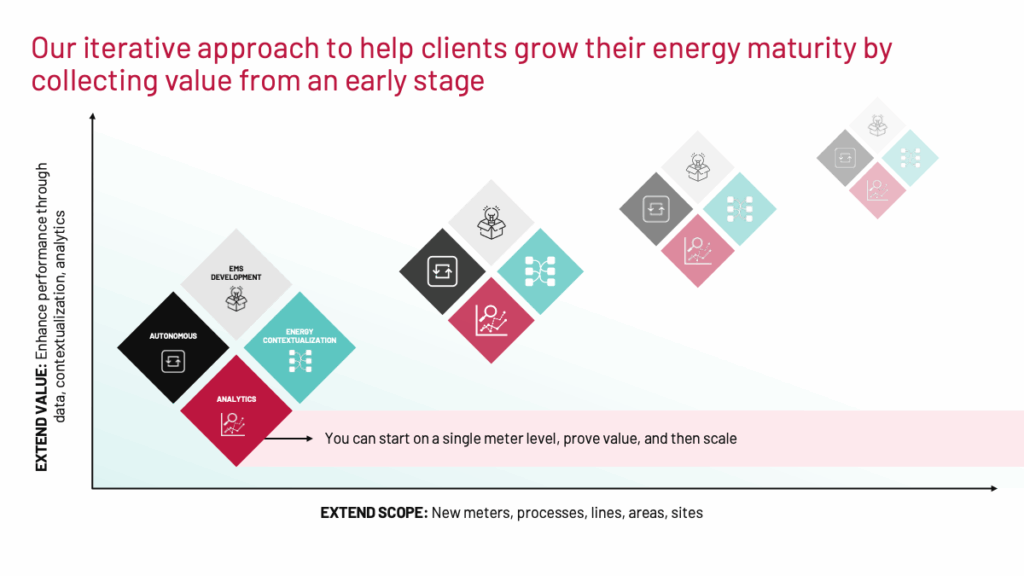

The journey starts with not only monitoring energy but also leveraging other types of data for optimization.

The first step is integrating energy data with production, product and operational information to contextualize how, where and why energy is being consumed across different parts of the plant.

Contextualizing energy data allows companies to enrich how systems and models generate insights into the factors influencing energy costs and losses –– including production, products, operations and external variables.

By integrating these data sets, companies can plan production schedules based on a more precise understanding of how different raw materials perform across various machines and production scenarios, optimizing gains in productivity and quality.

Moreover, this multifaceted data integration helps avoid unplanned downtime and anticipate machine breakdowns or raw material losses by detecting trends based on the historical performance of different datasets together.

The ROI is realized by not only reducing an organization’s energy bill but also by providing improvements in productivity and quality.

Enabling industrial energy management

To demystify and expedite the complexity of the energy management journey, companies should follow these steps:

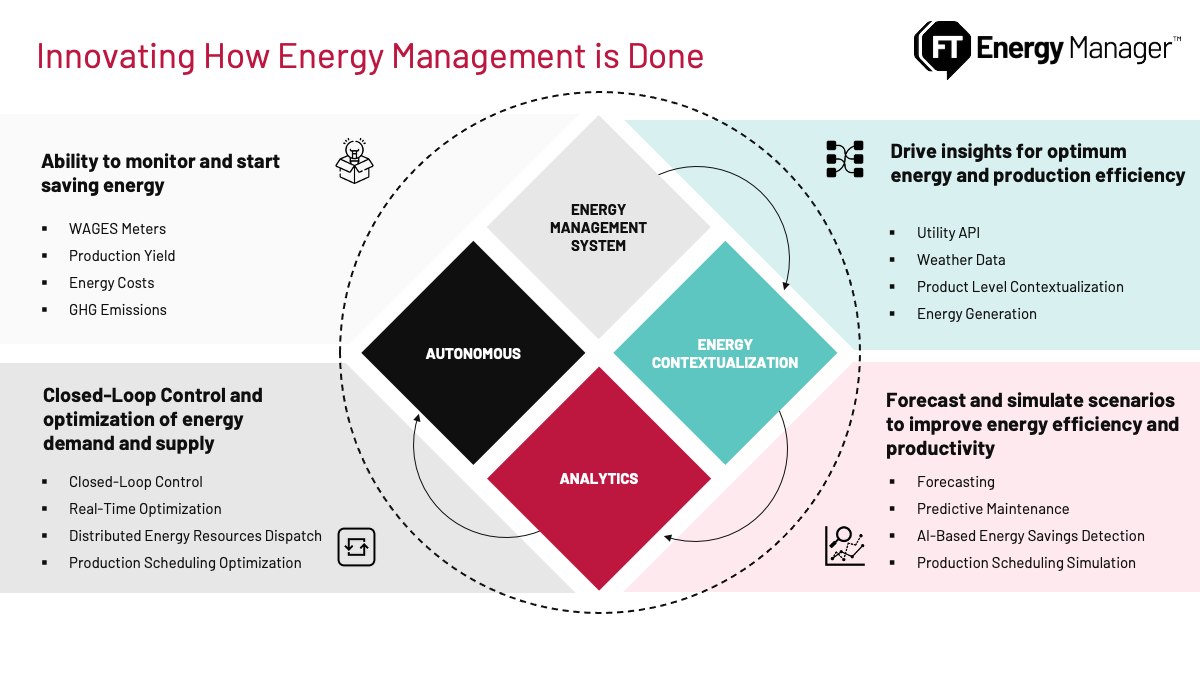

- Energy management system (EMS) deployment: The first stage involves deploying an EMS, which can be at a single meter level, delivering value even at small scales where meters are present. A new generation of EMS, which often uses an underlying data platform, offers advanced capabilities for monitoring and managing energy data, which can generate data-driven notifications of opportunities for improving energy performance and reducing costs. This can lead to significant energy savings and operational efficiencies.

- Energy contextualization: Energy consumption needs to be analyzed in the context of production processes. This may be achieved through data integration from other data sources, such as operational technology data from programmable logic controllers and manufacturing execution system or information technology data such as enterprise resource planning, weather and utility data. Contextualized data enables powerful use cases like detecting energy consumption anomalies versus production throughput, detecting energy loss areas with the highest potential for optimization, identifying and anticipating how internal and external factors influence energy waste, analyzing energy and production data from a financial standpoint and setting the foundation for the following analytics levels.

- Analytics: Real-time data and analytics can optimize machine and production performance, forecast energy consumption and demand and simulate production scenarios. This data enables companies to plan more effectively –– producing the rightproducts at the right time, using the correct machines to maximize productivity, improve quality and reduce costs. Machine learning models and predictive analytics help to read insights in between data patterns and provide insights for predictive maintenance and identify energy and material losses before they happen. These analytics-based methods enable better resource allocation, waste reduction and energy optimization throughout production or even on a single-machine level.

- Autonomous optimization: The next step is to transition from analytics to AI to enable optimization autonomously. Transitioning to autonomous control involves AI-driven closed-loop control of equipment parameters, such as through model predictive control or machine learning/AI agents that can minimize operator intervention while maximizing production yield and energy efficiency. Autonomous methods also facilitate distributed energy resource dispatch through real-time optimization, which helps supply different sources of energy more efficiently and cost effectively, enabling a lower-carbon future. AI-driven production scheduling optimization also can lead to further gains by accelerating reaction to scenario changes and triggering automatic workarounds when problems arise during machine operation.

Energy management for sustainability

The integration of energy management with production processes not only drives operational efficiency but also contributes to sustainability and environmental targets. By reducing energy consumption, minimizing waste and optimizing resource allocation, businesses can significantly reduce their carbon footprint. Adherence to regulatory standards and emissions reporting also becomes more streamlined with integrated energy management systems.

For example, by implementing these solutions and methodologies, a food manufacturer maximized capacity of the line while reducing energy usage. Using model predictive control, it achieved:

- 12% reduction in energy consumption

- 15% increase in throughput

- 60% reduction in quality variability

In another example, a solar company used forecasting and AI models to identify energy-savings opportunities. The solution focused on pinpointing panels causing significant losses and addressing challenges such as accurate energy loss calculation through AI pattern detection, root cause analysis via AI-based energy degradation analysis and AI-based potential energy generation calculations. This initiative resulted in:

- 2.5% reduction in power generation

- 100% tamper-proof service log

- 35% increase in solar operations uptime

- 50% reduction in service manpower

Paving the way toward energy efficiency

The journey toward revolutionizing energy management requires a paradigm shift in mindset and approach. By integrating digital technologies, data analytics and AI-driven solutions, businesses can unlock new opportunities for efficiency, sustainability and growth. From deploying advanced energy management systems to harnessing the power of predictive analytics and autonomous control, the possibilities are endless.

Companies can start on a single meter or at the equipment level, beginning with the most energy-intensive one onsite. By applying these concepts with a narrower scope, the value will be proved faster and the path to scale to new meters, equipment, lines and sites will be easier and simpler from a technological and business standpoint.