Intelligent energy management solutions enable industrial operators to optimize energy use, reduce costs and enhance plant performance.

Learning Objectives

- Understand how intelligent energy management solutions can improve operational efficiency and reduce energy costs in industrial settings.

- Learn about real-world case studies showcasing the successful implementation and benefits of advanced energy management solutions.

- Recognize the importance of continuous monitoring and optimization in achieving long-term energy efficiency and sustainability goals.

Energy management insights

- As global energy demand rises, industries must prioritize energy management to optimize consumption, reduce costs and enhance operational efficiency.

- Intelligent energy management solutions leverage real-time data and predictive analytics to improve reliability, minimize energy waste and enable companies to navigate market fluctuations while supporting sustainability goals.

- By leveraging real-time data and predictive analytics, these solutions address both financial and environmental objectives in a rapidly evolving energy landscape.

The global energy demand is expected to increase by 50% by 2050, according to the U.S. Energy Information Administration. In the United States, this surge is driven by factors such as electrification, the expansion of data centers and an increased emphasis on reviving the manufacturing sector. As energy consumption rises, so do operational costs, prompting industries to focus on efficiency gains as the quickest way to improve profitability.

Energy management solutions provide a pathway to achieving both financial and environmental objectives by enabling industrial operators to optimize energy use, lower operational costs and enhance overall plant performance through data-driven strategies.

Industries like oil and gas, petrochemicals and power and utilities consume vast amounts of energy, leading to significant operational costs and inefficiencies. Advanced energy management solutions address these issues by optimizing energy use, reducing costs and boosting profitability. By leveraging data, these solutions enable operators to make informed decisions, track consumption patterns, identify inefficiencies and implement targeted improvements.

Intelligent energy management at a coking plant

For example, a leading coking plant implemented an intelligent energy management solution to enhance electricity sales to the grid during favorable market conditions. The plant produces electricity using a mix of coke oven gas (COG) and natural gas to boost production during high price periods. The solution optimizes power generation by considering the cost of buying electricity and natural gas, along with the available COG.

By sending setpoints to the turbine through the distributed control system, the solution can dynamically adjust the turbine’s performance based on real-time data, cost considerations and available resources. The solution integrates cost and process optimization, ensuring efficient plant operation by enabling automatic updates to the electricity plan and facilitating participation in the intraday market. The solution allows the plant to adhere to an hourly electricity production schedule, thereby automatically reducing imbalances. Additionally, it enhances the control of gas header pressure, reducing flare discharges.

Energy management solutions monitor assets in real-time, predict and control performance and optimize processes based on energy costs. These capabilities ensure cost-efficient operations, which are crucial in a dynamic market characterized by frequent fluctuations in supply, demand and prices. By considering demand, efficiency and costs, these solutions optimize power production and consumption. Integrating them into existing control systems enhances operational efficiency, reduces energy waste, lowers carbon emissions and achieves significant cost savings.

How an industrial park transformed energy management

An industrial park faced challenges in ensuring a stable and cost-effective energy supply for its numerous companies. To address this, the operating company invested in its own power plant and an intelligent energy management solution.

The industrial park consumes as much energy annually as a large city with about 300,000 residents, posing significant challenges during periods of volatile and high energy prices. The power plant produces 300 gigawatt hours (GWh) of electricity and 600 GWh of heat (in the form of steam) per year, with any surplus supplied back to the grid.

The plant includes three gas turbines, each with a waste heat boiler, three steam turbines and a biomass boiler. These assets are optimized for efficiency and cost-effectiveness, considering daily market prices for electricity and gas. Depending on cost-efficiency, the plant generates energy internally or purchases it at lower prices.

The intelligent energy management solution monitors electricity, gas, heating and cooling demands across all locations. Operators access dashboards displaying key parameters and receive recommendations on which power plant units to use for optimal economic operation. With this solution, the industrial park reduced its energy costs by 1.5% in the first six months, allowing the investment to pay for itself within a year.

Additionally, the solution provided significant added value in mandatory forecasts for electricity feed-in and withdrawal. Deviations from these forecasts, whether positive or negative, are penalized by the grid operator. Before implementing the energy management solution, data collection and processing for more than 70 customers was time-consuming and labor-intensive, but the solution’s forward-looking planning made this process faster and more precise. The solution automatically determines necessary data, such as energy consumption, load profiles of turbines and current energy prices. The solution creates a next day forecast and automatically updates it for any changes, like unscheduled turbine shutdowns.

In just eight months, the industrial park reduced penalty payments by 60% for day-ahead forecasts and by 80% for intraday forecasts, saving significant working time. The technology ensures the attractiveness of the industrial park, allowing it to continue to serve as a vital economic hub with market- and customer-oriented infrastructure.

By providing real-time data and insights, intelligent energy management solutions enable operators to make informed decisions, reduce energy waste and improve reliability, ensuring a consistent energy supply and prevent power disruptions. Implementing scalable solutions results in substantial cost savings through enhanced operational efficiency and lower energy consumption.

Intelligent energy management in a virtual power plant

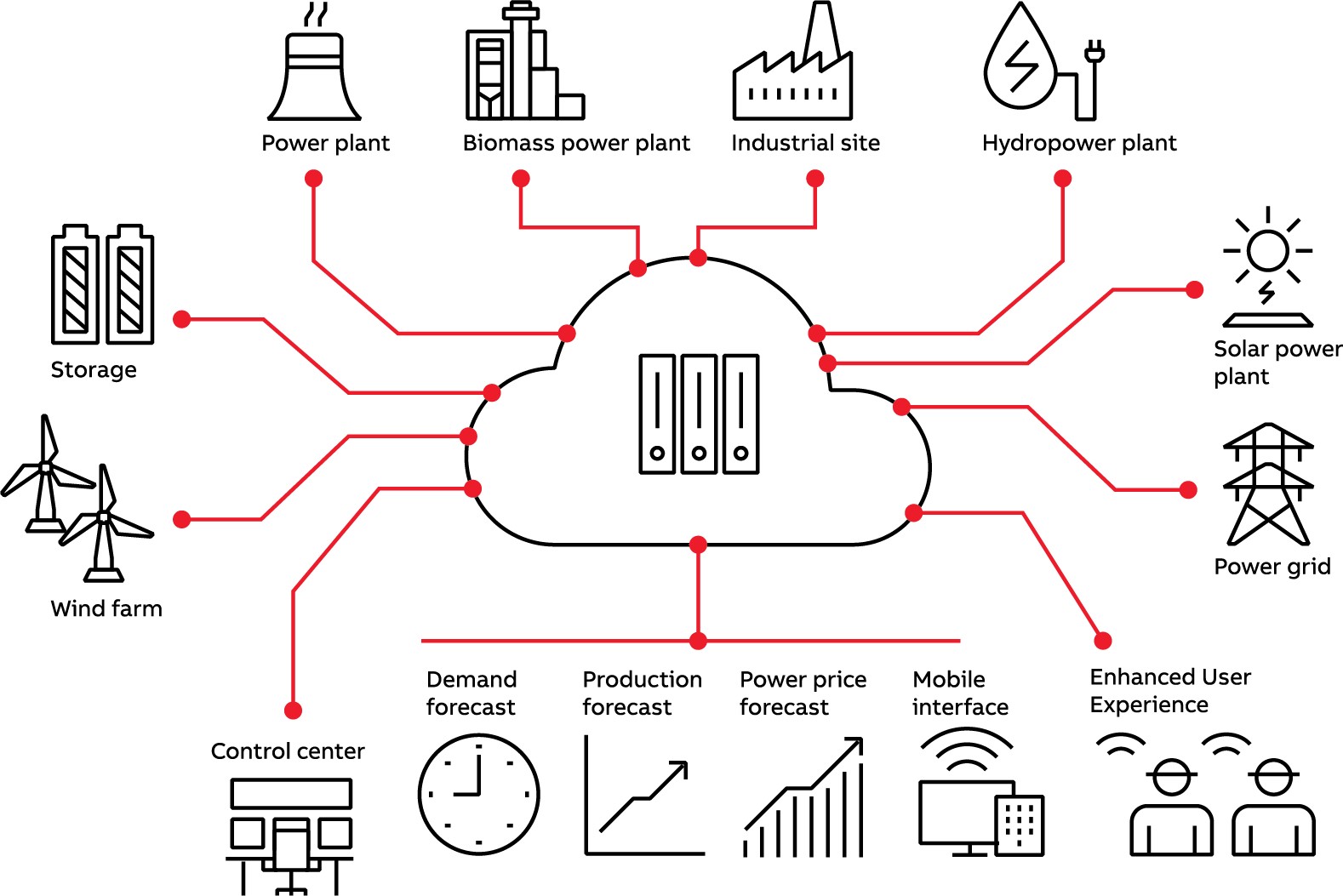

In another example, a European company implemented an intelligent energy management solution to create one of the country’s largest virtual power plants (VPP) for renewable energy. This solution aggregated the production of 9,500 small- and medium-sized renewable energy plants across eight countries, enabling participation in ancillary services and the spot market. The solution gathers production and grid balancing data, performs real-time optimization calculations and sets production schedules to ensure grid stability while adhering to plant constraints.

Ancillary grid services, used by transmission system operators (TSOs), maintain the balance between energy demand and supply. Imbalances can result from large power plant failures or intermittent energy sources like wind farms. When imbalances occur, the intelligent energy management solution handles commands from the TSO to adjust output in real time.

Initially, the customer was a VPP startup with just 20 biogas production units. Today, they have grown into one of the largest VPP operators in Europe, with more than 9,500 units producing 8,000 megawatts of energy. The VPP manages various biogas, solar, wind and water plants, mainly producing clean, carbon-free power.

To achieve this growth without risking downtime, the company needed a scalable solution with real-time operational views, user-friendly interfaces and configurable optimization modules. This approach improved operational efficiency and provided customers with energy trading flexibility from a single source. This solution benefits the VPP, the TSOs and the many small and medium-sized producers connected to energy markets.

For companies aiming to deploy intelligent energy management solutions, the first step is to assess current energy usage and identify areas for improvement. This involves leveraging existing data to monitor energy demand and supply. Implementing a phased approach allows for manageable integration and immediate benefits. You can’t manage what you don’t measure, and you can’t improve what you don’t monitor. Continuous monitoring and optimization are crucial for maximizing the long-term advantages of these solutions.

Intelligent energy management ensures energy is used where and when needed, optimizing consumption, reducing expenses and enhancing competitiveness. For industrial facilities striving to stay cost-effective, advanced energy management solutions are essential. By leveraging real-time data and predictive analytics, companies can improve energy supply reliability and reduce operational costs by up to 20%.

These solutions enable customers to monitor energy flows, automate operations and optimize energy efficiency, thereby minimizing their carbon footprint. Additionally, these solutions allow customers to actively participate in energy markets. As the energy landscape evolves, adopting these solutions will enable companies to navigate market fluctuations, enhance reliability and secure a competitive edge while supporting sustainability goals.