Modern industries should move beyond reactive maintenance and adopt a strategic combination of preventive and predictive maintenance, alongside smart upgrades and long-term planning.

Predictive maintenance (PdM) insights

- Predictive maintenance is rapidly replacing outdated reactive models, allowing industrial facilities to anticipate failures, reduce downtime and extend equipment life through real-time data and advanced analytics.

- By integrating PdM with preventive strategies and smart infrastructure planning, forward-thinking organizations are transforming maintenance from a cost center into a driver of resilience, efficiency and long-term growth.

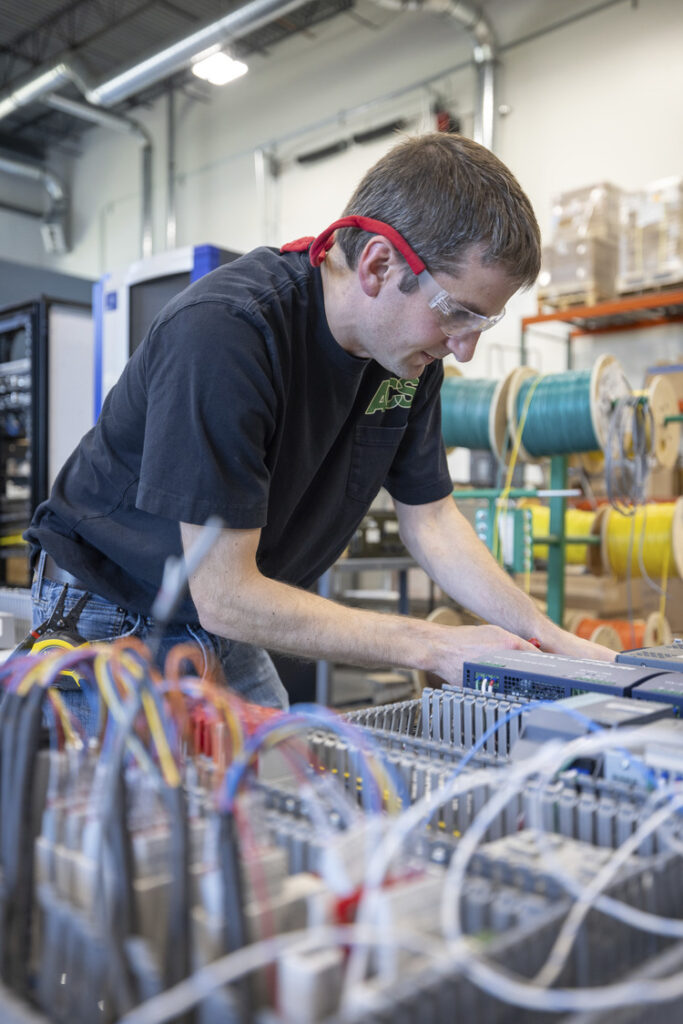

In industrial environments, companies invest significant capital in equipment and infrastructure, often ranging from tens of thousands to several million dollars. Maximizing the longevity and performance of these assets is not just a matter of protecting investments; it’s essential for operational efficiency and competitiveness. With the right maintenance strategies, systems installed decades ago can continue to function effectively today.

Achieving such durability, however, means abandoning outdated, reactive maintenance models. The “break-fix” approach — waiting for equipment to fail before acting — is still common, especially when resources are stretched thin. This philosophy is increasingly unsustainable. It leads to unplanned downtime, costly emergency repairs and elevated safety risks, particularly in environments where precise testing or continuous operation is critical.

The urgency to modernize maintenance practices is further amplified by the rapid pace of technological change. Equipment can become obsolete long before it physically fails. Since 2020, for example, the growth of electric vehicle research and development has dramatically shortened the typical technology cycle, requiring systems and processes to adapt more quickly than ever. Facilities that take a passive stance risk falling behind.

To address these challenges, forward-looking organizations are embracing a more integrated, strategic approach — combining preventive and predictive maintenance (PdM) with smart upgrades and long-term infrastructure planning. This approach blends engineering discipline, operational strategy and future-ready technology into a cohesive asset management philosophy.

Preventive and predictive maintenance

Preventive maintenance (PM) remains the cornerstone of reliable operations. It involves systematically inspecting, cleaning, calibrating and replacing parts at regular intervals or based on usage metrics. While these tasks may seem routine, they are essential to avoiding unexpected failures and preserving equipment reliability.

Neglecting PM has well-documented consequences: increased downtime, higher repair costs and compromised safety. In contrast, facilities that adhere to well-structured PM programs enjoy more consistent performance, longer asset life and improved operational control. Studies have shown that effective PM can reduce overall maintenance costs by 12% to 18% compared to reactive strategies.

Still, PM alone is not enough in an era of complex, interconnected systems. That’s where PdM comes into play. Unlike PM, which follows a schedule, PdM is condition-based. It relies on real-time data from sensors and digital systems to forecast failures before they occur.

Implementing PdM requires a technological foundation — sensors to collect performance data, software to interpret that data and algorithms to detect anomalies or predict breakdowns. These systems can flag early signs of wear or inefficiency, allowing maintenance teams to intervene when repairs are most cost-effective and least disruptive. The benefits are clear: fewer breakdowns, reduced maintenance costs and longer operational lifespans.

How PdM is better than deferred maintenance

The risks of reactive maintenance extend beyond equipment failure. Facilities themselves age and when their structural integrity is compromised, the effects ripple across operations. Roof leaks, worn flooring, failing heating, ventilation and air conditioning (HVAC)systems and outdated power infrastructure may seem like background issues, but they can jeopardize both safety and productivity.

In high-performance test environments, even minor infrastructure problems can halt operations or damage sensitive equipment. Water intrusion, for instance, can short-circuit electrical systems. Dust and debris from crumbling ceilings or corroded ducts can contaminate controlled environments. Unfortunately, many facilities rely on short-term fixes instead of investing in long-term upgrades, often because those upgrades weren’t included in the initial project scope.

Over time, deferred maintenance accumulates into significant liabilities, frequently demanding emergency capital outlays or complete system overhauls. Avoiding this outcome requires proactive infrastructure planning and embedding capital improvement strategies into the earliest phases of project development.

A holistic approach to planning

A robust maintenance strategy starts with strategic planning. At the outset of any major initiative, organizations must clearly define their objectives, align stakeholders and set performance and life cycle targets for both equipment and facilities. This alignment helps avoid short-term thinking and lays the foundation for adaptability as needs evolve.

Cross-functional collaboration is also key. Effective strategies require input from engineers, information technology professionals, operations teams and facility managers alike. Each group brings vital knowledge to the table, helping ensure that upgrades are both technically sound and operationally practical.

Furthermore, long-term success depends on designing facilities with flexibility in mind. That means planning infrastructure to accommodate future expansion, allocating budget for ongoing upgrades and coordinating among projects to avoid redundant systems. Instead of relying on temporary solutions, organizations benefit from phased upgrades and shared infrastructure that support evolving operational needs.

Allocating a small, consistent percentage of each project’s budget toward facility improvements helps ensure that infrastructure keeps pace with equipment demands. It also mitigates the temptation to cut corners when margins are tight, preserving long-term resilience.

How looking ahead can improve maintenance

Eventually, every system requires an upgrade. The most effective organizations don’t wait for failures to force change — they plan upgrades as part of a continuous asset life cycle. This process involves balancing technical rigor with practical innovation.

Data and analytics play a critical role. Performance metrics and predictive models help identify system weaknesses and guide upgrade priorities. At the same time, creative engineering enables facilities to incorporate new capabilities within existing footprints, leveraging modular designs, standardized interfaces and flexible configurations.

Rather than viewing upgrades as isolated capital events, forward-looking facilities treat them as integral components of their long-term growth strategies.

Making PdM smarter with technology

Emerging technologies are redefining what’s possible in maintenance and facility operations. Artificial intelligence and machine learning enable advanced predictive analytics, detecting failures before symptoms even emerge. These systems continuously refine themselves, creating a self-improving feedback loop.

Software-defined automation is also gaining traction, moving control functions from traditional hardware into the cloud or edge platforms. This shift allows for faster reconfiguration, remote updates and more adaptive system performance — all of which are essential for PdM and real-time monitoring.

Meanwhile, digital twins are providing new levels of insight into system performance. By creating a real-time virtual model of physical systems, digital twins allow engineers to simulate scenarios, assess efficiency improvements and guide maintenance decisions with greater precision.

When paired with smart infrastructure — self-regulating HVAC, intelligent lighting and responsive utility systems — these technologies create intelligent, adaptive facilities capable of anticipating and responding to operational demands.

PdM is becoming a strategic imperative

The age of reactive maintenance is over. In its place is a strategic model that prioritizes resilience, efficiency and future readiness. PM and PdM, combined with smart upgrades and long-range planning, enable organizations to extract maximum value from their assets while avoiding costly disruptions.

To thrive in the competitive landscape, manufacturing facilities must adopt a proactive mindset: setting clear goals, investing in technology, collaborating across disciplines and embedding maintenance into the core of operational planning.

Maintenance is no longer just about preventing breakdowns. It’s about building intelligent, future-ready operations that drive performance, support innovation and ensure long-term sustainability in an ever-evolving industrial world.