CFE Media and the Society of Tribologists and Lubrication Engineers (STLE) partner to bring you the 2020 Lube Guide

Good things happen when manufacturing operations use smart industrial lubrication practices and know how to select the right products for the job. Taking this approach will enhance the performance of any system that moves by helping it run more smoothly, efficiently and reliably.

That’s why CFE Media and the Society of Tribologists and Lubrication Engineers (STLE) are partnering to bring you this Industrial Lubrication Guide. STLE is a technical society that supports the men and women who develop and help you select the products featured in this guide. STLE is comprised of more than 13,000 individuals and 250 companies and organizations in the tribology and lubrication engineering business sector.

While lubricants and lubrication are familiar, the secret to their success comes from the field of tribology. Put simply, tribology combines engineering and chemistry to manage friction and wear to enhance productivity. The more exact definition is: “Tribology is the study of moving surfaces that interact with one another, including the science of friction, lubrication and wear.”

When applied in practice, tribology can enable advances to:

- Improved longevity and cost savings. Extend component life by reducing friction and wear in manufacturing equipment resulting in reduced replacement and operating costs.

- Improved safety. Help manufacturers operate equipment more safely resulting in reduced concerns surrounding disposal, waste, downtime and fluid compatibility.

- Improved productivity and efficiency. Help manufacturers improve the quality and quantity of outputs resulting in less waste, more uptime and reduced energy consumption.

This edition of the Industrial Lubrication Guide emphasizes the critical operational areas of condition monitoring, oil analysis and reliability maintenance. Proper sampling is the foundation of any lube analysis program. Irregular sampling procedures and inconsistent sample locations will lead to data that does not reveal problems adequately or is interpreted to identify a problem that does not truly exist, resulting in unexpected downtime or unnecessary repairs.

STLE has contributed several articles featured in the Industrial Lubrication Guide. The articles provide a clear understanding of the importance of proper sampling, instructions on choosing which assets to sample, from which location and how often. The Lube Guide concludes with a tribute to H. Peter Jost, the father of tribology.

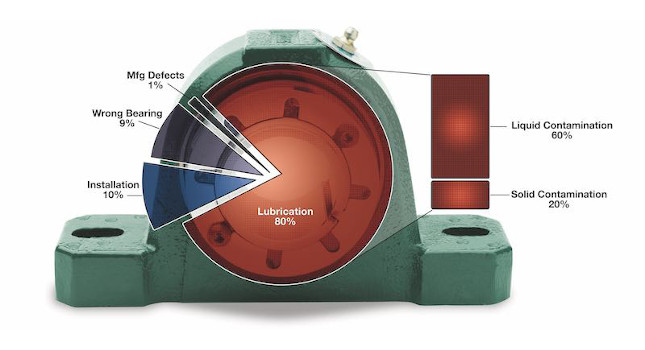

How to control industrial lubricant contamination. Over time, all assets requiring lubrication suffer a loss of usefulness. They break, become obsolete or, most often, stop performing at their intended levels because of surface deterioration from corrosion or some type of physical wear. The largest share of failures is from some type of contaminant that accelerates processes already going on.

Oil analysis fundamentals. Good maintenance judgment requires operators to take many factors into consideration. Getting the right answer depends on understanding the oil, equipment and operating conditions.

A tribute to the father of tribology. Tribology became widely acknowledged in the 1960s after an eye-opening British study: The Jost Report. It bears the name of H. Peter Jost, a British mechanical engineer who would become known as the founder of tribology. The report revealed that enormous financial losses were occurring due to the result of friction and corrosion.

Click here to download the 2020 Lubrication Guide.

There are more than 1,500 technical articles like these available at no charge through a searchable archive found on the STLE website. To learn more, go to www.stle.org and click on the Technical Library tab on the home page for access.

STLE offers many other benefits to professionals responsible for the safe and productive operation of manufacturing facilities. Membership is available to those interested in staying current in the latest technologies, advancing their careers and making new professional connections from around the world. STLE membership is a low-cost investment with high professional rewards. For more information or to join today, visit www.stle.org.