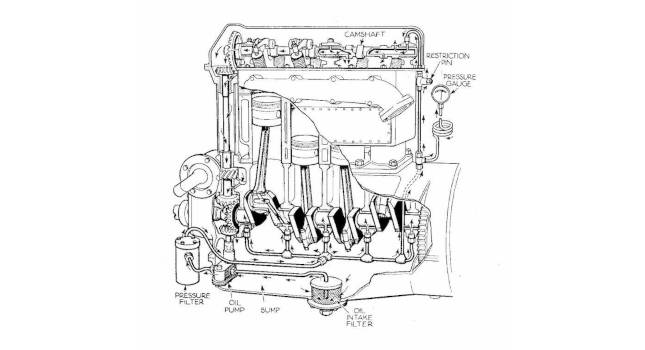

When, where, how much, and with what — these are the fundamental questions that have to be answered in equipment lubrication. The answers are normally provided by the builders of process and manufacturing equipment. However, maintenance personnel must sometimes address the "with what" question when finding substitutes for previously used lubricants.

|

When, where, how much, and with what — these are the fundamental questions that have to be answered in equipment lubrication. The answers are normally provided by the builders of process and manufacturing equipment.

However, maintenance personnel must sometimes address the “with what” question when finding substitutes for previously used lubricants. This exclusive guide, published at 3-yr intervals, provides quick identification of major lubricant sources and cross referencing of products.

The ideal lubricant would last forever and retain all of its properties. In reality, leaks, evaporation, heat, oxidation, and contamination combine to limit its service life. Properly answering the “when” question requires monitoring, by means of oil analysis, which is a fundamental component of modern lubrication and preventive/predictive maintenance programs.

Regular laboratory analysis indicates the health of both lubricant and machine. Viscosity, contamination, oxidation, acidity, and metals content are examples of parameters analyzed.

The “where” and “how much” concerns are good candidates for the visual approach to total productive maintenance. For example, lube fittings, filler caps, oil cans, and grease guns can be color-coded for the type of lubricant and the point of application. Captive plastic dirt caps for zerk fittings are available in a variety of colors. Color-coding is often carried over to lube diagrams, which are laminated and attached to equipment or carried on lube routes.

(PDF format)

Using the guide

This exclusive guide presents products from 118 companies who responded to our request for information. Some chose not to respond and you will find them missing. Product names, listed in each category, were provided by the manufacturers.

Presenting the data does not reflect the quality of the lubricant, imply the performance expected under particular operating conditions, or serve as an endorsement. Lubricant and equipment manufacturers should be consulted for specific applications or questions.

Viscosity a key factor

Viscosity is the property most widely accepted for identifying lubricants within a category. This characteristic serves as the basis for PLANT ENGINEERING magazine’s product listings. Viscosity can be specified in several ways. The Viscosity/grade comparison chart compares commonly used systems. In this guide, lubricants within each category are arranged according to ISO viscosity grade, with the corresponding Saybolt viscosity shown for reference.

Viscosity/grade comparison chart

| ISO viscosity grade | Kinematic viscosity Cst @ 40 C | Saybolt viscosity SUS @ 100 F | Gear lubricant specification | EP gear lubricant | Worm gear lubricant |

|

View guide (PDF format) Note that this guide covers only mineral oil-based products. A similar triennial guide is published for synthetic lubricants (PE, July 2003, p 30, File 8010). Click here to view the 2003 synthetic lubricants guide. |

|||||

| 2 | 1.98-2.42 | 32 | – | – | – |

| 3 | 2.88-3.52 | 36 | – | – | – |

| 5 | 4.14-5.06 | 40 | – | – | – |

| 7 | 6.12-7.48 | 50 | – | – | – |

| 10 | 9-11 | 60 | – | – | – |

| 15 | 13.5-16.5 | 75 | – | – | – |

| 22 | 19.8-24.2 | 105 | – | – | – |

| 32 | 28.8-35.2 | 150 | – | – | – |

| 46 | 41.4-50.6 | 215 | AGMA 1 | – | – |

| 68 | 61.2-74.8 | 315 | AGMA 2 | EP 2 | – |

| 100 | 90-110 | 465 | AGMA 3 | EP 3 | – |

| 150 | 135-165 | 700 | AGMA 4 | EP 4 | – |

| 220 | 198-242 | 1000 | AGMA 5 | EP 5 | – |

| 320 | 288-352 | 1500 | AGMA 6 | EP 6 | – |

| 460 | 414-506 | 2150 | AGMA 7 | EP 7 | Comp 7 |