Increase worker safety in semiconductor fabs

Risk mitigation begins with the workforce

Without the proper safety precautions in place, working in a semiconductor fabrication facility can be dangerous. On a day-to-day basis, semiconductor personnel face many different potential hazards. These range from the simple: body strains caused by ergonomic risk factors and slips and falls; to the extreme: exposure to pressurized sources like hazardous chemicals and gasses, and shocks from high electrical voltage.

But this needn’t be the case. If proper management and safety standards are put in place to minimize risk to workers, the entire operation will run smoothly. Some of the ways semiconductor facility managers can improve worker safety include conducting sitewide risk analysis, properly training technicians, prioritizing worker safety over keeping to a schedule, and performing routine safety audits.

Before beginning any work, it’s important to conduct a comprehensive risk analysis audit. This includes analyzing what tasks and processes are needed, determining the risks associated with each, and scoring them using failure mode and effect analysis (FMEA). FMEA is system that assigns numerical values to each potential process failure based on the probability of the occurrence, severity and detection of the failure. Using FMEA helps facility managers put safer processes into place and determine which tasks may need additional support and resources to guarantee safety.

Usually, sitewide risk analysis audits also include a job safety analysis (JSA), which is used to list all potential health and safety hazards associated with each task and dictate the best methods to avoid those hazards.

Off-site and on-site training

The best risk mitigation measure semiconductor facility managers can possibly take is investing in a thorough, careful and confident workforce. That is only possible by providing workers with extensive training, both before they begin working as well as on-site. Each worker should understand exactly what is expected of them and have a firm grasp of all the relevant safety procedures before they touch the equipment. Injuries are often caused by sloppy technique or general uncertainty, both of which can be avoided with the proper training.

Even when the actual work begins, it needs to be done in a constant coaching environment, especially for inexperienced technicians. Managers need to follow up with personnel daily to address various safety concerns.

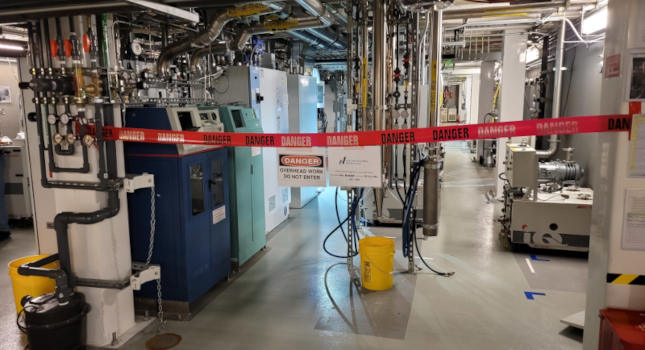

The biggest mistake manufacturing facility managers make that leads to injuries and other hazards is trying to stick to an unrealistic schedule. Rushing to meet deadlines and quotas leads to reduced worker oversight, sloppiness and procedural shortcuts, all of which increase the risk of accidents.

Rushing to meet deadlines and quotas can lead to oversights, sloppiness and other causes of accidents. Courtesy: NSTAR.

While missing deadlines may cost manufacturers time and money, it is nothing compared to the amount of time and money workplace injuries cost. Severe injuries can derail production for a long time, and come with hefty medical and legal bills.

Instead of rushing through procedures, the best way to meet deadlines is through careful planning and taking calculated steps to increase operational efficiency. Taking shortcuts may work initially, but it’s only a matter of time before the hazards catch up.

Perform routine safety audits

Another way to decrease the risk of accidents is by performing routine safety audits. Every facility should have dedicated safety officers whose job is to conduct periodic observations and audits to ensure all personnel are working safely and all tools are working properly. These audits allow facility managers to catch and fix potential problems before they occur and correct them in a timely manner.

Facility services partners in the semiconductor industry can help fab managers reduce worker risk and increase safety across the board by providing well-trained and experienced workers, implementing efficient yet careful procedures, and conducting sitewide risk analysis and routine safety audits.

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Click here to start this process.