Proper testing, adjusting and balancing (TAB) of ventilation systems in manufacturing systems is critical and is even more so when it comes to semiconductor manufacturing.

Learning Objectives

- Understand where ventilation systems are used in semiconductor manufacturing.

- Understand the key differences between testing TAB for building HVAC systems vs. production lines.

- Understand the most critical challenges for TAB in semiconductor manufacturing.

Semiconductor insights

- Semiconductor manufacturing demands precise and balanced ventilation systems, especially in areas below cleanrooms, where hazardous chemicals are handled, posing significant safety challenges.

- Coordinating adjustments to exhaust systems during tool upgrades is crucial to prevent production line disruptions, safeguarding against costly microchip rejects. This requires meticulous planning and expertise.

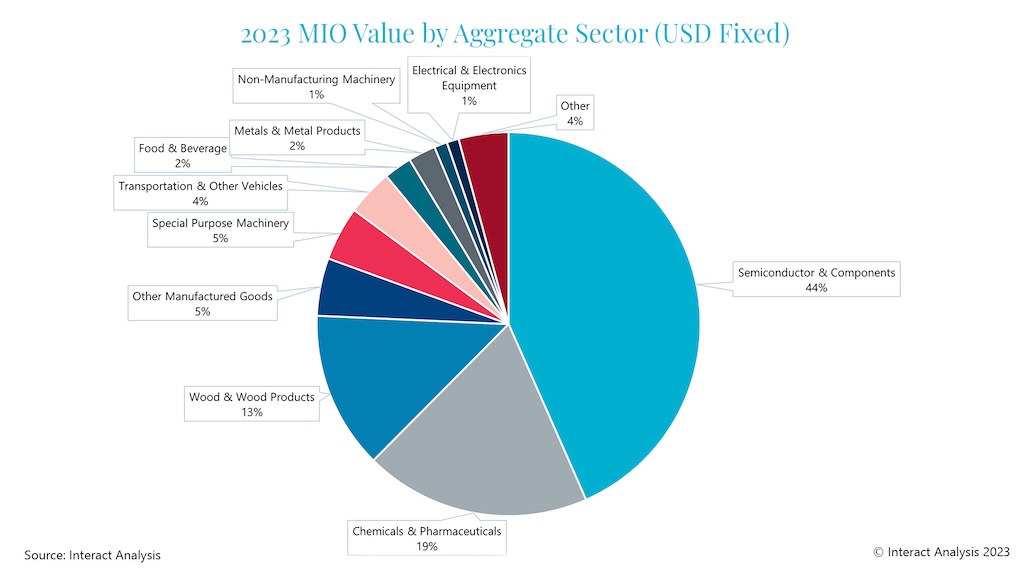

Semiconductor production is a hot business these days. Consumers have been experiencing this firsthand with tremendous lead times for durable goods, such as household appliances and automobiles. Repairs, including safety recalls, have been delayed for weeks or simply have not been worth waiting for, leading to premature retirement of equipment. Used automobiles are often worth more than their owner paid for them because the shortage of new vehicles has been so acute during the last few years. Large construction projects have been delayed and costs escalated as much of the equipment used in modern buildings is dependent on semiconductor availability.

In the United States, semiconductor manufacturing factories are being built as fast as companies can bring them online [1, 2, 3, 4]. One reason is supply and demand. The CHIPS and Science Act of 2022 [5] is another, promising $39 billion in manufacturing incentives.

The importance of TAB for semiconductor facilities

Testing, adjusting and balancing (TAB) for HVAC is critically important to energy engineers, as buildings use 40% of the energy in the United States [6]. It’s vital for facilities engineers, who need to make sure building occupants are comfortable and have sufficient fresh air to meet ASHRAE guidelines [7]. Hospitals have long been held to strict ventilation requirements for infection control and operating rooms [8]. Most recently, COVID-19 brought the importance of ventilation into discussions around the coffee machine in offices and schools, leading to a heightened emphasis on the need for certified TAB contractors. This is even more so when it comes to semiconductor manufacturing.

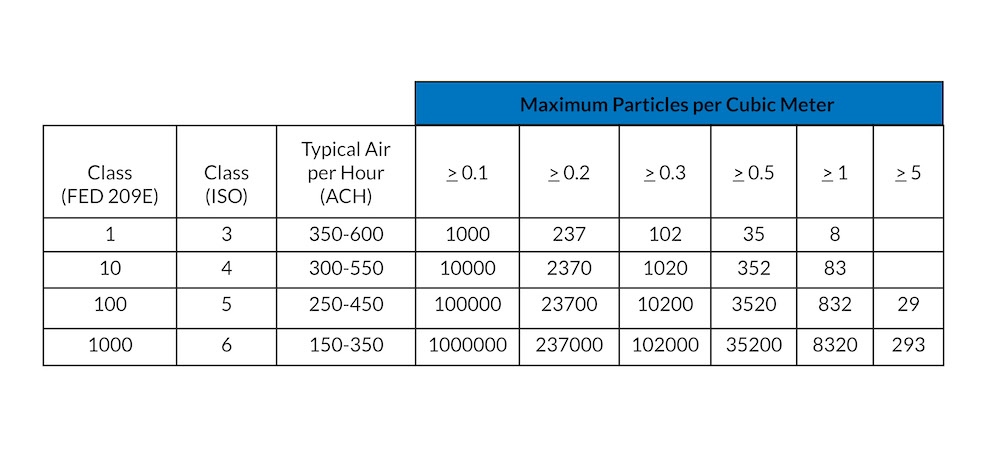

Anyone who has seen photos of semiconductor factories immediately thinks of cleanrooms, with people in white gowns, hoods, and gloves. Semiconductor manufacturing often requires Class 1, 10 or 100 levels of filtration, the requirements for which are shown in Table 1. This is attained with expensive filters and large quantities of air circulation, thus requiring a measured and balanced ventilation system.

From the TAB professional’s standpoint, this is the easy part of semiconductor manufacturing.

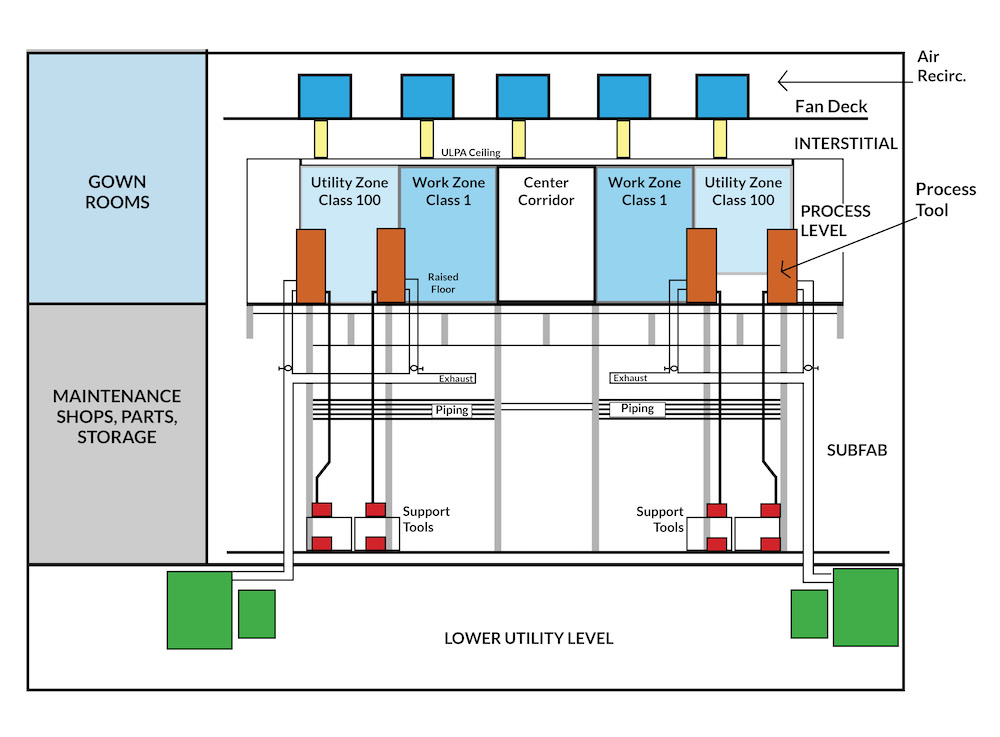

Cleanrooms take up very little space in the sprawling campuses typical of semiconductor factories. Most of the work done by specialized personnel takes place in the levels above and below the cleanroom floor where the process tools are located, as shown in Figure 1. For the TAB professional, the most vital work takes place in areas commonly termed the interstitial (one level above the cleanroom) and subfab (one level below the cleanroom). In particular, the level below the cleanroom (or in some factories, between cleanrooms) is the most challenging. This is where all the equipment required to operate the tool is placed, consisting of a multitude of cabinets and utilities delivering electricity, gases, and liquids to the cleanroom. The TAB professional’s job is primarily to balance several types of the tool’s exhaust products, some with chemicals that are hazardous to human health. Safety issues also arise because the ductwork typically requires ladders and harnesses, climbing in and around dozens of other wires, ducts, and tubes to get to the dampers and valves.

In the large factories typical of production scale fabrication, there may be dozens of tools connected to the same exhaust lines and each finely balanced on a system constantly running at maximum capacity to feed all the tools on the line.

The real challenge in today’s competitive environment is tools are constantly being upgraded or exchanged to permit newer technology microchips to be manufactured. This requires coordination among the equipment providers’ teams, factory production engineers, site facilities personnel, and TAB professionals as the exhaust systems are adjusted to ensure all other tools in active production continue operating within specifications.

An entire line can be brought down by a “tap of the hammer” that moves the damper 10% too far or a wayward bump of the elbow while crawling in and among the utilities. The result is a major financial loss as those semiconductor microchips must be rejected.

Added to this, a half-dozen other craftsmen, working on high and low voltage electrical, pipefitting, sheet metal, and other mechanical changes may be working in the same physical space at the same time. This is often referred to as “trade stacking” and everyone is under schedule pressures. The potential for hazards is much greater than it is in the cleanrooms, where people in white gowns work with automated equipment in discrete manufacturing cells. A few feet underneath them, a small city is humming with work as dangerous as those found on many large, heavy construction projects.

Another challenge is finding the right equipment to work on when aisle after aisle of the subfab appears nearly identical (see Ref. 1 for an idea of the scale of the buildings). This requires serious planning by the design and facilities teams, and rigor among every subcontractor, year after year, as tools are upgraded, new branches are attached to existing utilities, and new support equipment is brought online. Finding the right damper to turn frequently requires a pre-walk safety review, drawings which may or may not be correct, and in the case of the best-in-class companies, rigorous paperwork and comparison to drawings and tool owner work requests.

These are the reasons the trickiest part of TAB in semi-conductors is much more than meeting and validating cleanroom specifications. The limited number of TAB companies specializing in this type of business maintain databases that go back to when the plant was built. They hire and train technicians for a “no mistakes ever” mentality, and work with the customer and all the trade partners to make sure the work gets done safely and on schedule.

TAB in a semiconductor factory is tedious and hazardous. With the numerous configurations of ductwork in older and newer sections of the production line, they need to understand the intricacies of how flowrates, velocity profiles, and pressures are affected by ducting more convoluted than typically found in building construction. Worker and plant safety, keeping the production line operating and staying on schedule are major priorities.

So why do TAB companies choose this line of work instead of limiting themselves to more typical projects, balancing building HVAC systems? There is a financial aspect, of course, as regular work on one site is more efficient than hauling people and equipment to different job sites for short periods of time.

There’s a sense of pride in the importance of working in the high-tech industry, especially in a time when semiconductors are a key to strengthening the economic recovery after the COVID-19 pandemic. Perhaps the most important reason is the client is counting on them to be the experts in a rather obscure niche of the TAB industry and their decades of experience gives them a unique perspective.

Tom Prevish is a mechanical engineer and president of NWESI.

References:

- https://www.intel.com/content/www/us/en/newsroom/news/intel-announces-next-us-site-landmark-investment-ohio.html#gs.5ocjq3

- https://www.cnbc.com/2023/07/20/texas-becomes-chip-hub-with-47-billion-investment-from-samsung-and-ti.html

- https://www.azcentral.com/story/money/business/2022/12/07/what-to-know-phoenix-taiwan-semiconductor-factory/69707994007/

- https://www.micron.com/boise

- https://www.whitehouse.gov/briefing-room/statements-releases/2022/08/09/fact-sheet-chips-and-science-act-will-lower-costs-create-jobs-strengthen-supply-chains-and-counter-china/

- https://www.energy.gov/sites/prod/files/2017/03/f34/qtr-2015-chapter5.pdf

- ASHRAE/ANSI Standard 62.1-2022, Ventilation and Acceptable Indoor Air Quality, 2022.

- https://www.hfmmagazine.com/articles/1755-hvac-design-requirements-for-medical-spaces