Beckhoff's XTS drive system combines rotary and linear systems for mechanical engineers.

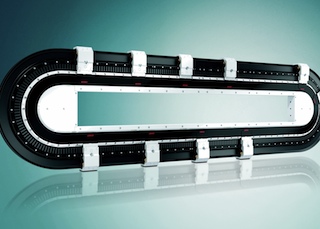

The XTS drive system (eXtended Transport System) from Beckhoff offers completely new freedom for mechanical engineering. XTS combines the previously separate advantages of two proven drive principles: Rotary and linear systems. The result is a new drive system that effectively turns the previous linear motor principle around. The motor is completely integrated together with power electronics and displacement measurement. One or more wireless movers can be controlled with high dynamics at up to 4 m/s on an almost arbitrary and flexible path. The XTS, with its compact design, revolutionises Drive Technology and makes completely new machine concepts possible.

XTS is an advanced mechatronic system containing all functions necessary for operation:

- A modular, fully integrated linear motor with power electronics and displacement measurement in one device;

- one or more wireless movers as the moving parts;

- a mechanical guide rail;

- an Industrial PC with TwinCAT control software

The desired geometries, lengths and radii are determined by the number and type of the components selected. Complex wiring and drag chains can be eliminated. In addition, the position measurement system is already integrated. The machine footprint is fully and efficiently utilised, since the outward and return path as well as the curves can be used for active material transport. In this way, not only is hardware saved, but so is expensive production space. Speeds of up to 4 m/s can be achieved with XTS while maintaining maximum positioning accuracy.

The new linear motor principle

There are virtually no limits to the application possibilities of XTS: The movers can accelerate, brake, position and synchronise themselves. They can take up absolute positions and positions relative to each other; they can group themselves and accumulate; they can create clamping forces in motion, drive through curves and along straights, recover energy through regenerative braking and use both the return paths and the outward paths for transport purposes.

This new linear motor principle gives rise to completely new possibilities in Drive Technology:

- Linear motor characteristics on an endless path;

- any desired number of movers on a common path;

- modular structure, simple adaptation to the application;

- low spatial and power requirements;

- simple implementation of demanding transport tasks;

- low project engineering and assembly expenditure

Plug-and-play: The XTS system components

The XTS system is simple and modularly configurable: the motor modules form a complete unit with the movers and guide rails. They contain the electromagnetic coils and all other active functions necessary for the operation of the system. The only further requirements are a power supply and an EtherCAT connection. The motor modules contain no moving parts and are not subject to any wear.

The mover contains magnetic plates which, together with the coils in the motor modules, can generate propulsive forces. It absorbs the attractive forces of the magnets on both sides and compensates them as far as possible. This means that the rollers on the movers, which are equipped with a particularly low-wear plastic surface, can move at high speed in the guide rails. A mechanically robust encoder flag conveys the mover position to the motor module.

Flow of material in packaging and assembly technology

XTS can be used in an unlimited number of ways in the most diverse industries. The solution is predestined for high-speed material handling:

- Push product, adapt product spacing, reduce or increase product speed;

- clamp and move product;

- transport and discharge product;

- manipulate product: lift out, close, rotate, screw cap on.

An irregular product flow is isolated and transferred at a constant interval and constant speed to the next workstation. Products are picked up and transported from one workstation to the next.

The distances in between are traversed at high speed if the path is free, or the products move in a travelling buffer to the destination. The products can be processed in parallel in groups at slow workstations. Fast stations only process one product at a time. The return path can always be actively used.