Embrace digital manufacturing and use data to provide customer value.

Manufacturing’s digital revolution arrives with a fundamental change in exactly what manufacturers deliver.

That was the message from ThyssenKrupp senior vice president Nihar Satapathy during his opening remarks at the 2019 ARC Industry Forum on Feb. 5 in Orlando. Satapathy told the 900 attendees at the annual forum that performance data available from any manufactured product will be just as valuable as the product itself.

“Data is going to be the currency of the future,” Satapathy said. “Data is what’s driving most of the value. The data already exists; we just have to figure out how to use it in a different way. The customers of tomorrow will not expect you just to build something for them. They will want you to help them anticipate changes.”

Take a fresh perpsective

Embracing those changes are important for customers. Satapathy added it is also a business imperative, as well. “The reason you need to digitally transform is that you are at the risk of being out-competed in the market,” he said. “We find ourselves having to compete every day.”

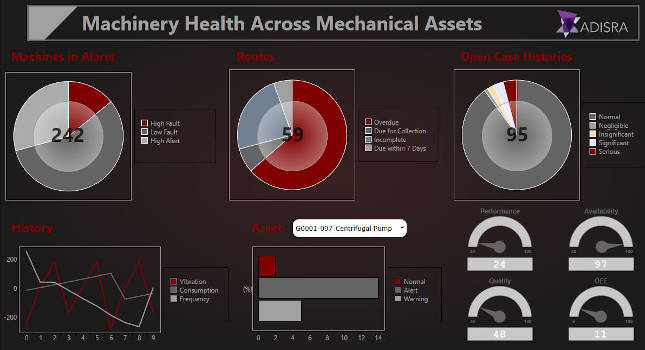

For ThyssenKrupp, that meant taking a fresh look at fundamental product offerings like elevators. It also meant transforming the elevator into a device that constantly communicated its machine health and availability. This allows companies to intelligently deploy maintenance teams and efficiently use equipment.

“With data, companies are interested in understanding the flow of people within a building,” Satapathy said. “So, what exactly is the product we’re selling?”

Satapathy said ThyssenKrupp learned several lessons that applied to manufacturers in general such as:

- Digitalization is inevitable whether you like it or not. Embrace it sooner than later.

- Technology is available today. Manufacturers need to find a relevant business case to create customer value.

- Partnerships are important, so leverage relationships and be open to new ways of engagement. “We realized early on we did not have resources to do it ourselves,” Satapathy said.

- Stay the course—it will be worth it, and it will also be game changing.

- It’s a journey, so prepare for the long haul with time, effort, and resources.

Part of that journey is to remain aggressive about moving forward because technology continues to accelerate. “We, as all of you have, went through the process trying to stay one step ahead,” he said. “We focused on customer value-add. If you can do that, you can find a way to monetize it.”

ONLINE

See additional stories from ARC Industry Forum on the Control Engineering and Plant Engineering websites.