Newport News Shipbuilding is constantly seeking new technology and innovative ways to improve safety, quality, cost, and schedules. Since 2007, they have explored augmented reality as a means to shift away from paper-based documentation in the work environment.

Over the next decade nearly 3.5 million manufacturing jobs likely need to be filled. The skills gap is expected to result in 2 million of those jobs going unfilled. More than 75 percent of manufacturers say the skills shortage has negatively impacted their ability to expand and 69% of manufacturers expect the shortage in skilled production to worsen.

To address the 21st century skills gap challenges, businesses are looking at innovative ways to become more competitive to sustain and win the global economic marathon. The Association for Manufacturing Excellence (AME) has adopted a new vision for a "Manufacturing Renaissance" driven by "People Centric Leadership coupled with Enterprise Excellence". This initiative is seeking innovative new ways to enable the transfer of knowledge quickly to the workers so they can affectively do the job right the first time and every time.

During WWII there was a critical need to train replacements of an industrial workforce that went off to fight the war. It was in a time of crisis that Training Within Industry (TWI) programs proved its worth to win WWII. Using a common "lean" language, TWI levels the flow of training to smooth the transfer of knowledge, and now organizations are turning to TWI again.

Newport News Shipbuilding (NNS) was an early adopter of the TWI programs during WWII and is now enhancing its effectiveness by coupling TWI principles with augmented reality application coined "Augmented TWI". Shipbuilding has been the perfect environment for industrial innovation for hundreds of years. Sails to steam, wood to iron, rivets to welds, blueprints to CAD, stick-built to modular construction-all major innovations to building extraordinarily complex vehicles. Newport News Shipbuilding is constantly seeking new technology and innovative ways to improve safety, quality, cost, and schedules. Since 2007, they have explored Augmented Reality as a means to shift away from paper-based documentation in the work environment.

These efforts are being led by Patrick Ryan the founding leader of the Augmented Reality (AR) Program at Newport News Shipbuilding (NNS). He also leads the development and engineering functions of AR at both NNS and their commercial teaming partner, Index AR Solutions in Williamsburg, Virginia.

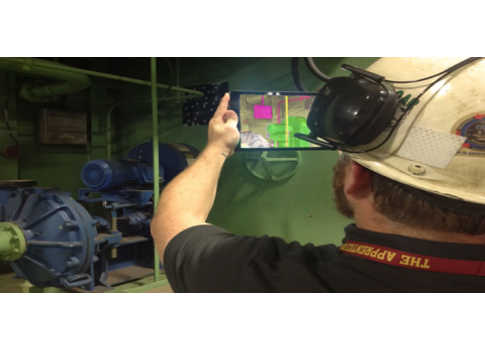

Mobile AR technologies can create solutions that include step-by-step instructions using visual overlays of the right information on equipment, machine, and panel operations. AR solutions visually enhances a worker’s access to information required to perform a job including steps, cautions, knowledge from expert workers, schematics and any other digitized data. It provides seamless and timely transfer of knowledge and key points to workers on the job.

AR is much easier to understand once experienced. AR overlays digital information onto the physical world through a window—like an iPad. In shipbuilding, the potential applications are enormous, including comparing a 3D product model to its physical counterpart, planning and training for future work, step-by-step maintenance instructions, and highlighting potential safety concerns. AR delivers more information in an intuitive way—making every shipbuilder and sailor more knowledgeable and capable.

-Glenn Marshall is a member of Association for Manufacturing Excellence (AME). This article originally appeared on www.ame.org. AME is a CFE Media content partner. Edited by Erin Dunne, production coordinator, CFE Media, [email protected]