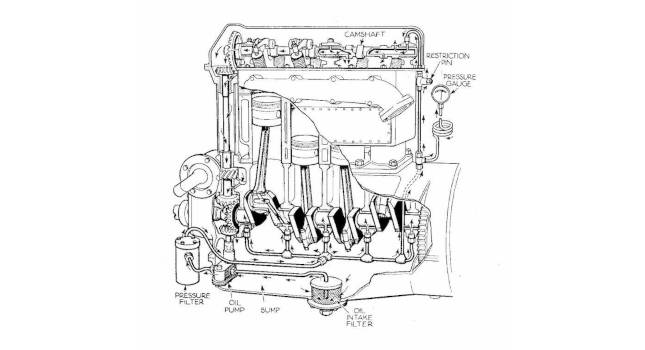

Machines require rotating shaft seals to retain lubricants and prevent foreign particles from entering sealed cavities, which damage machinery and lead to premature failure.

Machines require rotating shaft seals to retain lubricants and prevent foreign particles from entering sealed cavities, which damage machinery and lead to premature failure. Application conditions can vary considerably, and many seal designs have evolved to satisfy these conditions. Some applications tolerate a small amount of leakage, while others cannot allow any leakage. In general, seal complexity and cost increase as the need for zero leakage increases.

Shaft seals make up two groups: contacting and noncontacting. Contacting seals make direct contact between the sealing component and the rotating shaft. Because there is rubbing contact, leakage is minimal and friction and seal wear occur.

The sealing element in noncontacting seals allows a certain amount of leakage. It is controlled by clearance gaps. Because there is no rubbing contact, leakage is higher, but seal friction and wear are eliminated.

Contacting

There are three types of contacting seals.

Mechanical face seals prevent leakage in applications that exceed the capabilities of elastomeric radial lip and packing designs. They provide long life without shaft wear. Shaft finish, hardness, and material are not critical. The seal can handle a wide variety of fluids, pressures up to 3000 psi, speeds to 50,000 rpm, and temperatures from -425-1200 F. This type of seal has become popular on pumps where leakage is not allowed.

Radial lip seals are primarily used to retain lubricants and exclude contaminants. The seals function at temperatures from 60-400 F. Advantages include low cost, small space requirements, and simple installation.

Packings are not designed to produce a leak-free seal. They are tightened enough to allow a minimum, but positive, leakage. The leakage is intended to lubricate the packing material. The modest leakage reduces friction and wear. Packing material is supplied in many shapes, including impregnated yarn, continuous strands, square-sections, and interlocking shapes. This seal is generally used on pumps.

Noncontacting

Four types of noncontacting seals are available.

Bushing seals are classified as fixed, floating, balanced, and floating ring. The bushing seal is a close-clearance version arranged stationary to the housing or floating with the shaft. The fixed bushing is a sleeve attached to a housing, surrounding a rotating shaft with a relatively close clearance.

Floating bushing seals follow shaft gyrations and have closer tolerances than fixed bushings. Balanced bushing seals eliminate or reduce spring forces and still retain the advantages of a floating bushing seal. Floating ring seals overcome the pressure and alignment problems of single floating bushings by splitting the bushing into several rings. This seal is only suited for sealing liquids.

Labyrinth seals are used mainly in high-speed applications where relatively high leakage rates can be tolerated and simplicity is necessary. A properly designed seal does not require lubrication or maintenance. If wear occurs, the only damage is an increase in leakage.

Visco seals have grooves or screw threads machined on the shaft or in the housing to provide a positive pumping action. Viscosity of the pumped fluid in the clearance gap produces the seal effect. These seals function at certain minimal speeds. For low shaft rotation, a secondary-sealing device, such as a lip seal, must be provided. This type of seal is used where liquids are continuously transferred.

Magnetic seals use a colloidal suspension of magnetic particles, focused by permanent magnets, to create a seal. In addition to providing a nearly perfect seal with negligible wear or friction, they are tolerant of shaft runout. They can be used at speeds up to 120,000 rpm, temperatures up to 400 F, and pressures of 7 psi/stage. Seals are used primarily with gases and exclude moisture, mist, and fine solids.

&HEADLINE>Rotating shaft seals&/HEADLINE>

&BYLINE>Joseph L. Foszcz&/BYLINE>

&TEXT>

Contacting seals

Mechanical face

Radial lip

Packing

Noncontacting seals

Bushing

Labyrinth

Visco

Magnetic

Troubleshooting mechanical face seals

SymptomCauseCure

Narrow wear pattern

Excessive pressure

Reduce pressure or change to higher pressure-rated seal

Wide wear pattern

Cocked stationary face Pump or pipe misalignment Pump cavitation or vibration

Clean and reassemble seal Realign pump Check system piping

No wear pattern

Rotary seal interference

Disassemble and remove obstruction

Intermittent wear pattern

Distortion of stationary face

Check stuffing box face for flatness Tighten gland bolts evenly Check seal faces for flatness

Uneven wear pattern

Pump/motor misalignment

Realign pump and motor

Heat checking

Seal faces overheat

Add flushing to seal faces Change seal design or material

Cracked hard face

Thermal or mechanical shock

Change seal material Handle seals with care

Chipped edges

Fluid vaporization Pump cavitation

Properly flush seal Check system piping

Flaking and peeling

Defective coating Chemical attack

Switch to solid seal material Change seal material

Deep wear on hard face

Fluid is abrasive or crystallizes

Flush to remove abrasive products Add heat to inhibit crystallizing

Troubleshooting radial lip seals

SymptomCauseCure

Leakage

Nicks, cuts, or tears in seal lip

Remove burrs and sharp edges from shaft Use mounting tool to protect seal lip from keyways, sharp shoulders, and splines Handle with care

Scratches or nicks on shaft surface

Finish shaft to 20 (omega)in. rms Protect shaft after finishing

Lead marks on shaft

Plunge grind shaft surface

Shaft whip or runout

Locate seal close to bearing

Cocked shaft

Use correct mounting tool and procedure

Damaged spring

Use correct mounting tool and procedure Handle seals with care

Damaged case

Use correct mounting tool and procedure Handle seals with care

Paint on shaft or seal

Mask seal and shaft before painting

Turned under lip

Rough chamfer

Machine chamfer to 32 min. and blend into shaft surface

Chamfer angle

Check for correct lead angle

Careless handling

Use correct mounting tool and procedure

Excessive lip wear

Pressure

Provide vents in housing

Rough shaft

Finish shaft to 20 (omega)in. rms

Dry running

Provide proper lubrication for seal

Element hardening or cracking

Temperature

Reduce sump temperature Upgrade seal material Provide proper lubrication for seal

Shaft wear

Abrasives

Use dust lip in dirty atmospheres Harden shaft to Rc 30 minimum Change oil frequently to remove dirt Install wear sleeve

Troubleshooting packings

SymptomPossible causes/actions

No leakage

Incorrect installation- negative stuffing box pressure requiring lantern ring Slight overtightening- follow installation procedure

Excessive leakage

Wrong packing Incorrect installation procedure Shaft runout excessive

Packing reduced under horizontal shaft

Shaft misaligned with stuffing box Worn bearings- packing acting as bearing

Packing reduced over horizontal shaft

Shaft misaligned with stuffing box Worn bearings

Whole or part of end ring missing

Excessive clearance between shaft and stuffing box neck or gland follower, allowing extrusion

Wear on outside of one or more rings

Rings rotating with shaft, packing section too small

Rings next to gland follower worn, others all right

Incorrect installation procedure, gland follower overtightened

Ring IDs burnt, dried, or charred, remaining material all right

Incorrect packing selection for temperature or speed Inadequate lubrication

Innermost ring deteriorated

Incorrect packing selection, check compatibility with product

Packing seizure on shaft after shutdown

Product crystallizing or solidifying in packing bore through inadequate lubrication or lack of cooling or heating

Troubleshooting noncontacting seals

ProblemCausesCorrective action

Excessive leakage at startup

Excessive radial clearance

Decrease radial clearance

Excessive pressure

Improve or add vent

Excessive lubricant fill

Decrease fill or increase cavity

Excessive temperature

Decrease fill or increase cavity

Excessive vibration

Increase lube cavity

Excessive end play

Increase lube cavity

Radial contact

Fill scratches and voids

Bypass leakage

Replace damaged secondary seals

Excessive leakage after a period of time

Loss of lubricant viscosity

Improve lubricant

Excessive relubrication

Decrease lubrication

Contaminant ingress

Add contaminant shield

Loss of magnetic fluid

Replace magnetic fluid

Water ingress

Static leakage

Add static seal

Partial vacuum

Clean or add vent

No lube leakage

Increase lube fill

Excessive wet environment

Add water shield

Dirt ingress

Excessive radial clearance

Decrease radial clearance

Excessive dirty environment

Add dirt seal

Partial vacuum

Clean or add vent

No lube leakage

Increase lube fill