Key concepts Misconceptions about fires often come from what we have seen on television or in movies. Many widely held beliefs about fire protection are untrue.

Key concepts

Misconceptions about fires often come from what we have seen on television or in movies.

Many widely held beliefs about fire protection are untrue.

Properly installed and maintained systems in all areas of a plant can drastically reduce damage potential.

Most fire protection engineers would agree that there are many misconceptions about fire damage and suppression equipment. While no amount of fire protection can guarantee absolute immunity, a careful analysis of hazards, combined with the proper selection of fire protection systems, can drastically reduce potential damage.

Unfortunately, laymen often misunderstand the recommendations given by fire protection professionals. And since “unfriendly” fires do not happen to most of us on a regular basis, we have images of fires seen in movies or on television. In order to offer the viewer a clear picture, movie directors typically use clean-burning natural gas flames in the fire scenes, which are unrealistic at best. To accurately portray most fires, the director would have to show a black screen. Misconceptions like these often make people confused about fire protection. The following are some of the most common fire protection-related myths.

Myth 1. Keep sprinklers away from electricity

Electrical fires can produce large quantities of opaque, corrosive, and toxic smoke. This smoke makes any manual fire fighting efforts-such as using a portable extinguisher-extremely difficult. Most electrical and electronic equipment exposed to sprinkler water can be cleaned, rinsed with deionized water, and dried.

Almost always, the fire protection layman opposes the presence of sprinklers in an electrical room because of “personnel hazard.” This argument is weak because everyone should already have left the room long before a sprinkler actuates. In most cases, hazards caused by the fire and its products of combustion are much greater than that of the water discharge or potential for contact with a live circuit. Even in a case where sprinklers actuate with a person in the room, such as if he was unconscious, the chances of being harmed by the water discharge are much less than from the deadly smoke.

Myth 2. Don’t use water on flammable liquid/oil fires

While it is true that a straight stream of water when applied to a flammable liquid fire can actually spread the burning liquid, it is a poor reason to exclude the use of water at all. Water is an excellent fire suppression agent used to successfully control and extinguish flammable liquid fires, if properly applied.

Let’s take a brief look at the physics of burning liquids. Every flammable/combustible liquid has a flash point-the temperature at which the liquid gives off a flammable vapor in sufficient concentration with ambient air to generate an ignitable mixture. So in reality, it is not actually the liquid that burns, but the vapor.

The proper application of water to a flammable liquid or oil fire has several effects.

1. Water absorbs convective heat above the fire. If it is not absorbed, this heat can cause structural damage and ignite other nearby combustibles.

2. When applied to structural members, water provides a cooling effect to keep the materials from failing (for example, structural steel begins to weaken at 800 F).

3. Water extracts heat from the liquid itself, so that when the liquid is cooled to below its flash point, the fire self-extinguishes.

The method of water application is the key to properly extinguishing a flammable liquid fire. Trained fire fighters use a spray or fog pattern from their hoses in order to accomplish the three items discussed above. Fixed sprinkler and waterspray systems achieve the same effect, but begin suppression earlier, distribute water more evenly, and cause much less damage than the fire department would, assuming that they even attempt offensive fire fighting.

Another important aspect of flammable liquid fire control is proper spill containment. If a pool or “burning” liquid flows outside a sprinkler-protected area, no sprinkler system will do the job. Therefore, containment must be limited to the areas protected by the fire suppression system, and for ease of control, the area should be subdivided into smaller sections.

Myth 3. Sprinklers do more damage than fire

Sprinklers provide early control of a fire, thus providing safety and limiting the damage. With the exception of the deluge sprinkler/waterspray system (which is only used for specific high-hazard applications), sprinkler heads only operate when heat released by a fire melts the fusible link that keeps the sprinkler closed, and the open sprinklers can be expected directly above the fire seat. Every individual head must be triggered in that fashion.

Myth 4. Sprinklers may go off accidentally

The failure rates for sprinkler heads are extremely small (on the order of 1 in 16 million or a probability of 6.25×10 -8 ). Inadvertent discharge of sprinklers is extremely rare and usually attributed to mechanical damage or poor system design. It is so rare, in fact, that there are not enough data to be more precise. It is estimated that 1 in 2.5-million installed sprinkler systems will discharge inadvertently (probability of 4.0×10 -7 ).

To ensure reliability and performance, sprinkler system components, design, and installation are meticulously controlled by the National Fire Protection Association (NFPA) standard, NFPA 13, Installation of Sprinkler Systems, the nation’s foremost design and installation standard on the subject. Proper selection and location of sprinkler heads, and proper system design, minimize the possibility of inadvertent discharge.

Myth 5. Plants that meet fire and building codes don’t need additional protection

Fire and building codes objectives are to get the occupants out safely before conditions become hazardous, rather than to protect the building from fire. Since industrial fires have not historically resulted in extensive loss of life, most building and fire codes tend to be fairly lenient in industrial facilities. In addition, these codes usually do not concern themselves with the adequacy of fire suppression systems, but merely address whether or not their presence is required.

Industrial fire losses do, however, constitute a high percentage of the annual property losses, a factor that the codes usually do not address. Also, model codes used by most jurisdictions only contain minimum requirements, even though builders and owners often look at them as maximum requirements.

If the “codes” don’t address property loss prevention, how can you make sure that your plant is adequately protected? Industrial insurance carriers with a technical background can offer a wealth of information and support ranging from management loss prevention programs to special hazard fire suppression protection.

Myth 6. It is better to rely on manual fire suppression

Manual fire fighting efforts are a last resort when attempting to confine and contain a fire within a plant. By the time the local fire department is notified and arrives at the scene of a working fire, extensive damage to the building and contents has already occurred. Add to that the extensive water damage from 1-3/4 or 2-1/2-in. hose streams (250-500 gpm). In the case of large fires or high-hazard buildings, the officer in command may decide to take the defensive position of letting the fire burn itself out and protecting neighboring structures rather than jeopardizing the safety of firefighters.

Effective fire fighting is much harder than portrayed on television and in movies. Few people realize that a typical fire extinguisher provides only 10-15 sec of agent discharge. Unless the fire extinguisher is used in the incipient stage of a fire and the operator is familiar with the extinguisher’s proper use, they are of little benefit to facility protection. Often, valuable time is wasted emptying fire extinguishers when the fire department should have been notified immediately.

Using a fire hose can be much harder than it looks. Many 1-1/2-in. “occupant” hoses are inadequately maintained and could result in injury if used. Smoke quickly impairs visibility, and products of combustion can turn a room into a deadly trap within minutes.

For anything other than small, incipient fires, the best thing to do is to leave the area immediately, notify the fire department from a safe location, and let the suppression system (if installed) do its job.

Myth 7. Firefighters know fire protection systems

While surveying an industrial plant, the inspector noted that the preaction sprinkler system valve protecting a fairly large building of wood construction had been turned off. When questioned, the facility’s safety officer replied that he would check with another employee who was a retired firefighter, which he did promptly. The retired firefighter informed the safety officer that the impaired sprinkler system was “legal” because plant personnel were concerned about inadvertent sprinkler discharge and that someone would open the system valve (located in the fire area) in case of fire.

This incident reaffirms the misconception that firefighters know all about sprinklers and other fire suppression systems. Had the retired firefighter been familiar with the operation of the plant’s suppression systems, he would have known that the concerns were unsubstantiated because preaction sprinkler systems are virtually unsusceptible to inadvertent discharge and that the valve would not be safely accessible during a fire.

The fact is that firefighters are trained to deal with fire fighting tactics and rescue; their training and knowledge on fixed fire protection systems is usually limited. Fire protection systems are engineered mechanical, electrical, and structural systems whose evaluation should be left to fire protection engineers and their care to experienced contractors.

Myth 8. If the plant has sprinklers, it’s protected

While sprinklers have an excellent record of protecting people and buildings from fire, the mere presence of a sprinkler system does not mean that it can adequately deal with a fire. This point is especially true in facilities with often-changing hazards.

Sprinkler systems are matched to the occupancy of a building, meaning that the higher the expected heat release of a fire, the more water a sprinkler system must be able to deliver. The density, or water flow over a unit area, is a balance between the available water supply (flow and pressure) and friction resistance of the sprinkler piping. Engineering calculations are used in the sprinkler system layout and the pipe selection. Therefore, a sprinkler system that was adequate 10-yr ago may not necessarily offer adequate protection today.

Myth 9. Halon is toxic and illegal

At this time, no laws or regulatory agencies in the U.S. prohibit the use of Halon as a fire suppressant. When used as intended as a total flooding or local application fire suppression agent, no adverse health effects have been reported from the use of Halon 1301 and 1211 over the past 30 yr. At the typical 5-7% concentration, the volume of Halon is insufficient to displace a significant percentage of oxygen. Exposure to Halon at high concentrations only causes temporary adverse health conditions.

Decomposition products of Halon from exposure to flame or surface temperatures over 900 F can be harmful. However, products of combustion from the fire itself (carbon monoxide and hydrogen chloride) are a greater danger. As long as occupants leave the area within 15 min of a Halon system discharge, do not reenter it immediately after a fire, and the space is well ventilated after a discharge, Halon is a safe fire suppression agent.

Myth 10. Testing diesel fire pumps is bad

I have heard numerous comments from maintenance personnel, such as: “We have reduced the speed of the diesel driver to lessen wear on the engine.” “We would like to install a clutch between the engine and pump, which we can disengage during our weekly tests to minimize wear on the engine.” “We want to install a high-temperature cut-out to prevent the engine from overheating.”

These points may be appropriate reasoning for a truck or industrial engine, but they could be the cause for catastrophic losses if a diesel fire pump fails when needed. The main focus behind any fire protection equipment is maximum reliability when needed. As such, fire pumps and their diesel engine are intended for emergency service, not for maximum mileage and wear, as in the case of the truck engine. Therefore, it is imperative that only the minimum necessary mechanical and electrical systems be provided, as deemed necessary by the manufacturer, listing agency, and fire protection experts.

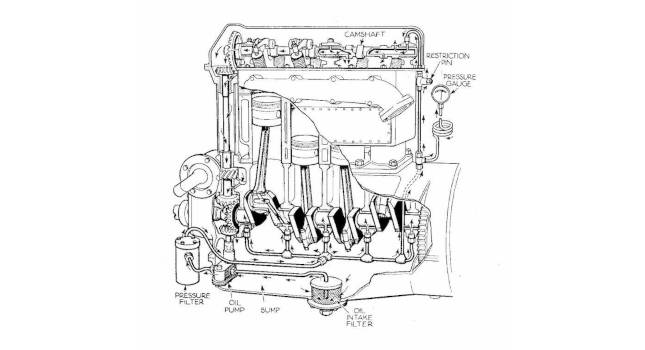

While it is true that wear increases due to poor lubrication when the diesel engine is started under full load and brought up to its rated speed within 1-2 sec, a fire pump engine should not log more than 30 hr/yr, including weekly and annual testing. Excessive wear over the engine’s life should not be an issue.

When problems with diesel drivers are occasionally encountered, it is usually due to poor maintenance and/or operating procedures. For example, infrequent oil changes can result in corrosion, due to the moisture content in the oil; or leaks in hoses can result in overheating, due to low coolant level. With the proper care, as recommended by the manufacturer and NFPA, a diesel fire pump assembly should give many years of troublefree service. This service is the case with thousands of fire pump installations throughout the U.S. and the world.

-Edited by Cheryl Firestone, Senior Editor, 630-320-7136, [email protected]

&HEADLINE>Do sprinklers cause more damage than the fire itself?&/HEADLINE>

According to a study conducted by Factory Mutual, 56% of fires are controlled and extinguished by three or fewer heads, making the extent of damage from sprinklers relatively small.

A typical sprinkler head discharges about 20 gpm, meaning that three heads would discharge approximately 60 gpm. The required waterflow alarm notifies the fire department and plant personnel so that sprinklers can be secured after the fire department has established that the fire is out. Thus, in the majority of cases where sprinklers actuate, fire damage can be expected to be small, and water damage would be confined to approximately 400 sq ft. Often, total damages due to sprinkler discharge are less than $5000, and they go unreported.

In contrast, fires have destroyed entire buildings and plants where sprinklers were absent.

&HEADLINE>Role of changing hazards&/HEADLINE>

A building constructed as a metal assembly plant had a sprinkler system approved and installed to adequately protect the occupancy. Several years later, this company moved out and a plastics manufacturing company moved in.

Their raw materials are thermoplastics, which are stored in racks. The heat release of a fire involving plastics in a rack storage arrangement is many times higher than a fire involving metal production operations. In this case, the hazard has just been increased to the point where the existing sprinkler system would be ineffective.

This deficiency would not likely be picked up during a fire prevention inspection, nor by the technician who performs the routine testing of the sprinkler system. The proper evaluation of a fire protection system necessitates information about the occupancy, the sprinkler system design, and the water supply.

&HEADLINE>More about Halon&/HEADLINE>

At this time, this author knows of no laws or regulatory agencies in the U.S. prohibiting the use of Halon as a fire suppressant. In accordance with the Montreal Protocol on Substances that Deplete the Ozone Layer of 1987, a complete phase-out of Halon production is mandated by 1/1/2000. However, all U.S.-based firms producing Halon voluntarily stopped the production of Halon several years ago. Halon is still commercially available mainly from recycling.

In most cases, the installation of a new Halon system would not be justified due to the availability of alternative agents. Existing users of Halon can still get cylinders refilled through many fire protection contractors, although one system discharge could end up costing almost as much as the installation of a new alternative system. To have Halon cylinders recharged, estimate about $25/lb, however, this figure may increase due to future additional taxes.

Note: Halon should not be confused with carbon dioxide (CO2) as a fire suppressant. Because of the larger required concentrations of CO 2 (34-50%) to extinguish fires, human life cannot be sustained. The threshold level of CO 2 at which harmful effects become noticeable is about 7%. Therefore, CO 2 is best used only in unoccupied areas as a total flooding fire suppressant.

&HEADLINE>More info&/HEADLINE>

The author is available to answer technical questions regarding this article. Mr. Dieken can be reached by e-mail at dominique_dieken@ hsb.com. HSB Professional Loss Control can be reached at 423-376-1131. The company web site is www.hsbplc.com.

For more information, visit the web site of the NFPA at www.nfpa.org, or the Factory Mutual web site at www.factorymutual.com.

For general information about this subject, visit the “Fire protection, safety, and health” channel at www.plantengineering.com.