Although offline or static testing is an important part of a routine maintenance program, dynamic testing of motors can be done more frequently and, in many cases, with greater benefit.

When properly installed in the correct application, electrical motors fill a particular need. If well cared for, they can operate safely and economically for many years. In fact, they were designed to work indefinitely. However, in most cases issues are going to occur that need to be addressed. After all, the motors may operate in a facility that subjects it to any number of different environmental or operational problems. This could place stress on the motor and potentially result in motor failure.

When the electrical systems fail at a place of business, regardless of whether it is a motor failure or a power failure, it can result in unexpected losses. Those losses can be felt financially, as well as through the level of production. The problems are more likely considered when the failure occurs unexpectedly which is why it is so important to have a preventative maintenance program in place.

A preventative maintenance program can test the motors at a facility to determine if they are operating within acceptable limits. In many cases, the testing of the equipment will determine if problems do exist even before they become apparent with a visual inspection. A maintenance program should not be thought of as a system to diagnose the problem after it takes place. It should be an ongoing process to reduce the likelihood of a catastrophic failure along the way.

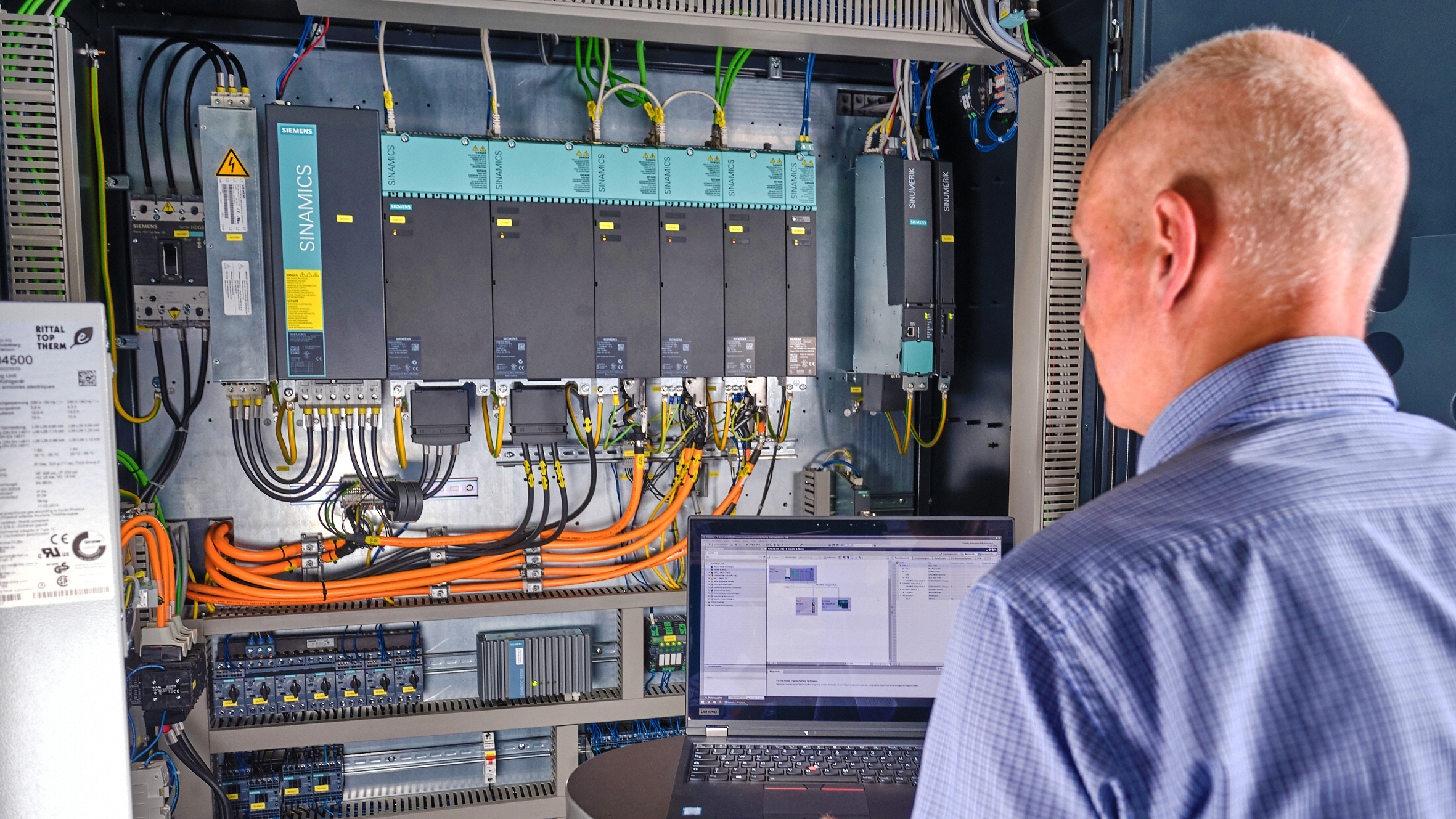

Although there are several ways to test industrial motors, one of the better options to consider is online motor testing. There may be a need for periodic off-line motor testing, but online or dynamic testing typically yields the most benefit with a preventative maintenance program. This type of testing is done while the motor is operating within its normal environment at standard loads. It provides a variety of information including the existence of undesirable conditions such as imbalance, high or low voltage levels, and distortion.

The biggest benefit of online motor testing is watching how the test is performed. Since the motor does not need to be taken out of service to be tested, it is a nonintrusive type of test. It can typically be done without any interruption in productivity, and depending upon the kind of test that is done, it can be done quickly. This type of data collection is also safe with some of it even being performed without coming into contact with the motor itself.

Online motor testing can not only determine if there are any electrical problems with the motor, but it can also test a variety of other issues within the system as well. This includes any misalignment, vibration, or problems with the bearings.

Although offline or static testing is an important part of a routine maintenance program, dynamic testing of motors can be done more frequently and, in many cases, with greater benefit.

-David Manney is a marketing administrator at L&S Electric. This article originally appeared on the L&S Watts New blog. L&S Electric is a CFE Media content partner.